Compendium of Foreign Body Detection - Part 3

Determination of Critical Control Points

What people consume must be pure. This is one of the most important commandments of the food industry. A crucial criterion in this regard is that your products are delivered free from metal contamination and other foreign bodies. The inspection of products for metallic foreign bodies has become an indispensable element of responsible food production and an integral part of an HACCP concept (Hazard Analysis and Critical Control Points) or a prerequisite for successful IFS certification.

What are critical control points?

Within the framework of a comprehensive and systematic HACCP concept, it is not sufficient to only examine the end product for contamination, as there is a risk that impurities in the raw material may be fragmented during processing to the extent that they can no longer be reliably detected during the final inspection. Therefore, controls must be carried out at various points in the production process to ensure optimal food safety. The HACCP concept involves identifying all points where a lack of monitoring poses an unacceptable health risk to the consumer. These points in the production process are referred to as CCP (Critical Control Point). To establish the correct CCPs and thus achieve a safe HACCP concept, an analysis of potential hazards in the production process must first be created - the so-called hazard analysis.

The hazard analysis

In the course of the hazard analysis, all physical, chemical, and biological hazards that could potentially occur must be identified. Physical hazards include, for example, contamination of the product with metals, glass shards, bones, etc. Furthermore, a risk assessment must be conducted. On one hand, it analyzes how likely contamination is estimated to be, and on the other hand, what impact such contamination would have. In summary, the following questions should be answered in the hazard analysis:

- What contaminants could occur during production?

- How likely is it that these contaminants will occur?

- What possible consequences would these

- contaminations have?

Identification of Critical Control Points

The use of a decision tree has proven to be a useful aid for the targeted identification of critical control points. At the identified CCPs, inspection systems such as metal detectors or X-ray scanners are used to detect and signal possible contaminants or automatically separate them.

Critical Limits

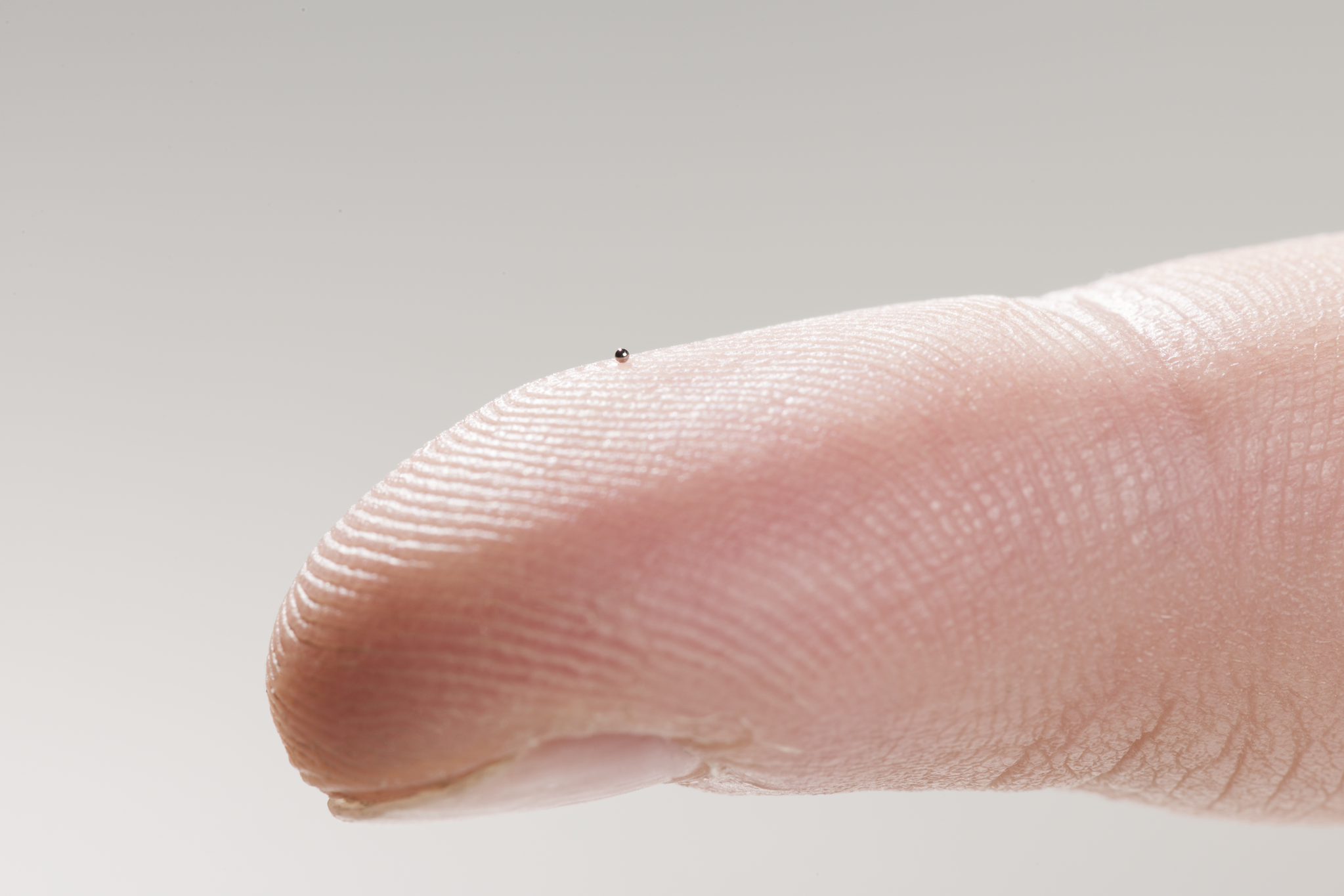

Once the critical control points are established, specific limits are defined for each of these control points. Only if these limits are adhered to is food safety ensured. When using metal detectors or X-ray scanners, the limits mainly refer to the sensitivity, i.e., the size of the detectable contamination, and the associated signal or ejection devices.

Setting up a monitoring system

For each critical control point, monitoring systems are established to check compliance with the specified limits and indicate any loss of control. This is done with metal detectors and X-ray systems, for example, using test bodies with which the functionality of the devices is checked at regular intervals.

Taking corrective actions

If it is determined at a critical control point that the limits are not being adhered to, previously established corrective actions must be carried out.

Explore the four parts of our compendium.

PART 1

Basics of Metal Detection

This chapter provides an overview of the role and effectiveness of industrial metal detectors in the food industry.

PART 2

X-ray Inspection Systems for Food

Learn how X-ray detectors identify organic and inorganic contaminants in food products.

PART 4

Testing Contaminant Detectors According to BRC Standards

This guide explains how and when to test the performance of your inspection technology.