FOREIGN BODY DETECTION

Precise Food Inspection. Pure Pleasure.

The safer and more efficient food production becomes, the better it is for people and the planet. With smart technologies and services, Sesotec helps the food industry achieve this goal. For safe and sustainable food production free from foreign bodies – and quality without compromise.

Product Inspection: Why It Matters

To eliminate foreign bodies in delivered goods, responsible food producers rely on machine product inspection. This is an integral part of every HACCP concept and a prerequisite for successful certification, such as IFS or BRC. Moreover, it protects manufacturers and brands from liability claims, recalls, and reputational damage.

Early detection and removal of metal contaminants and other foreign bodies through inspection systems prevent damage to production facilities.

Reducing waste and recalls minimizes production downtime and food waste, boosting customer trust and positively impacting your long-term revenue.

YOUR INDUSTRY

Tastes better without foreign bodies

Sesotec empowers food producers to achieve uncompromising food safety. Our systems are especially suited for the following products:

Enhanced Security, Fewer Hassles

272

Food Recalls

occurred in Germany alone in 2024

2.

most common reason

for food recalls in Germany 2024 is foreign bodies in the product

Our solutions for the food industry ensure you're not part of the problem.

Source: Lebensmittelrückrufe.de

.We see what you don't...

- Control Accessories

- Metal Wear

- Stones

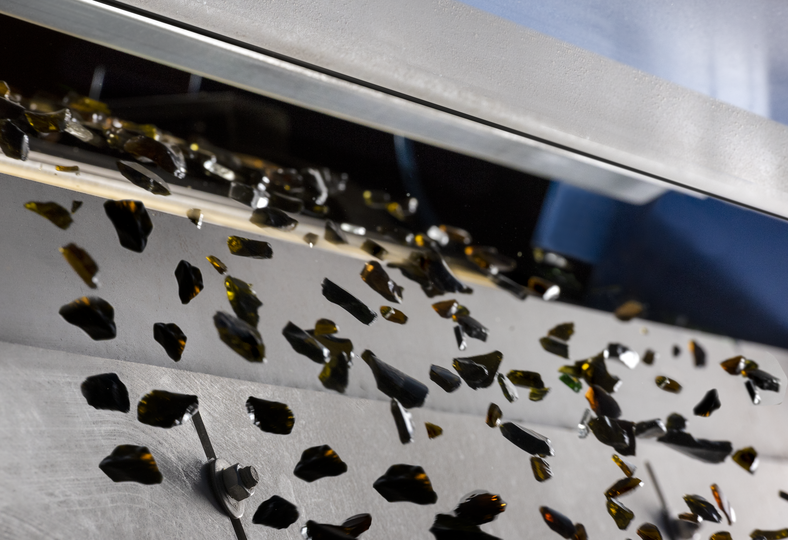

- Glass

- Bone

Small objects such as parts of chainmail gloves, hairpins, or ballpoint pen tips can unintentionally enter the food during production and pose a significant risk to the consumer safety.

Abrasion or tiny metal particles from machines and conveyors can silently infiltrate food products, posing a significant contamination risk.

Stones introduced through raw materials are a common foreign body in food processing and can significantly compromise product quality.

Glass shards from broken lamps or containers pose a significant threat to food safety and can lead to serious health consequences.

In meat, fish, and poultry products as natural or processing-related residues.

Pure food, pure safety

After a food safety incident,

68%

of consumers would stop buying from a brand.

Sesotec's state-of-the-art detection systems prevent food recalls caused by foreign bodies.

Source: NielsenIQ survey 2022

Know What Matters

Food must be safe and pure—a fundamental industry mandate. However, contamination from machine wear or handling tools can never be completely ruled out. Consumers and retailers demand the highest quality and certifications.

Our systems reliably detect and remove metals, foreign bodies, and quality defects.

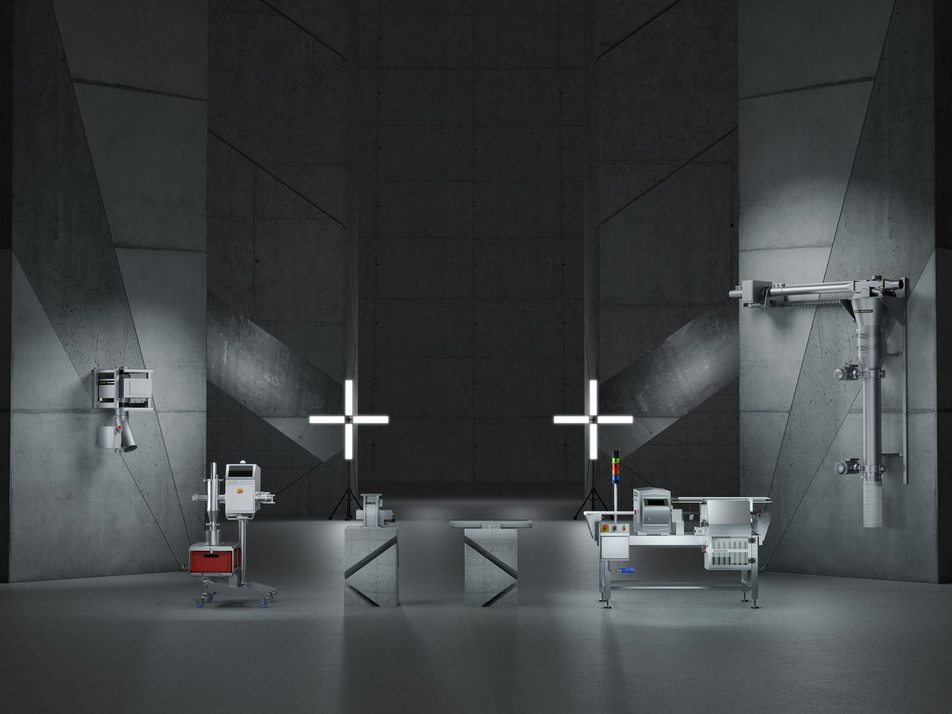

OUR TECHNOLOGIES FOR THE FOOD INDUSTRY

Modular Solutions for Every Application

No matter which of our three focus industries you're in or what specifications your machines require, our technology helps you conquer every challenge. Explore our use cases and key solutions to discover the perfect Sesotec solution for you.

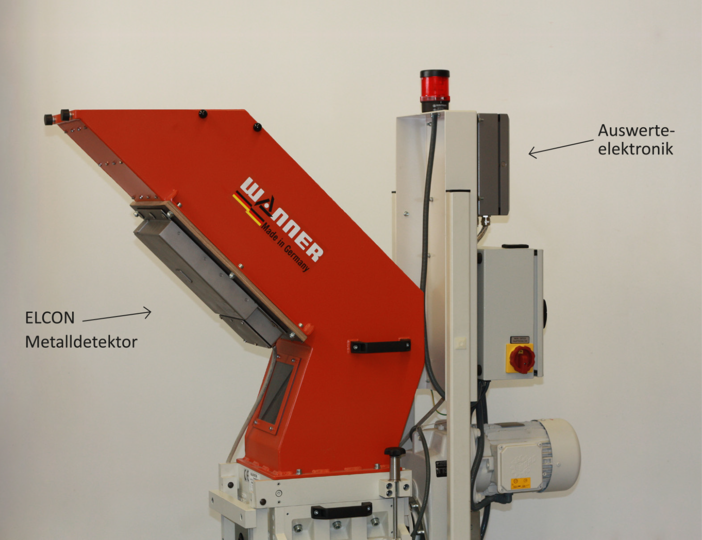

- METAL DETECTION

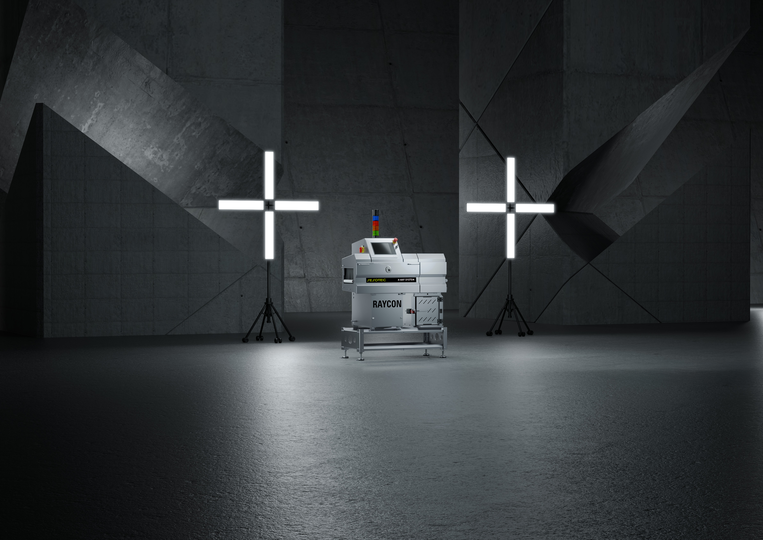

- X-RAY INSPECTION

- Magnetic Solutions

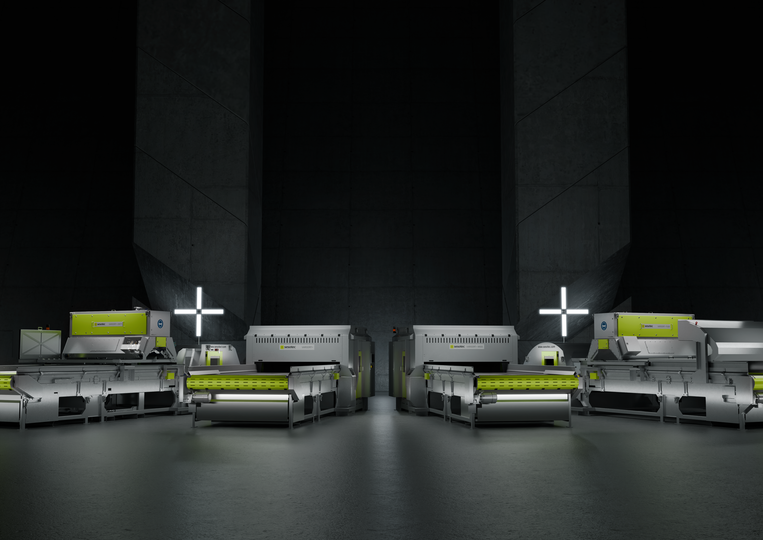

Our Solutions for Metal Detection

Whether it's iron, stainless steel, or non-ferrous metals like aluminum, copper, and brass, our metal detection systems use inductive technology to identify any type of metallic foreign bodies. Sesotec devices comply with industry standards such as IFS, BRC, and FSMA, enabling the fully automatic removal of contaminated products.

READ MORE

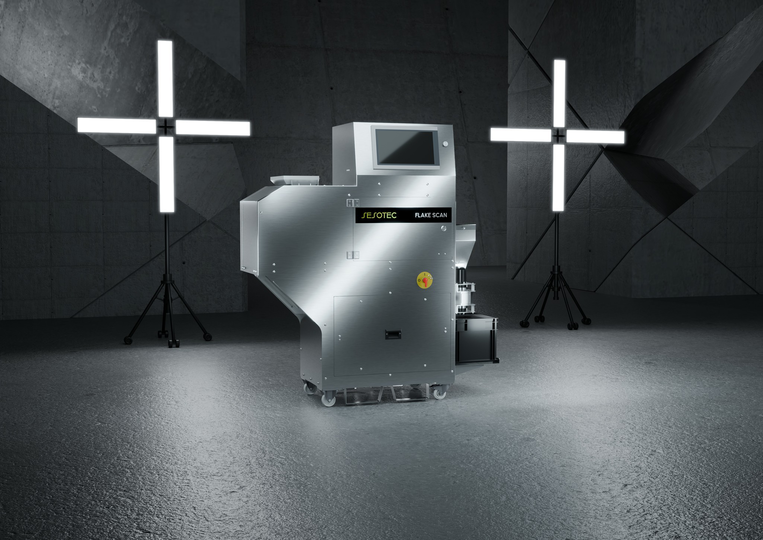

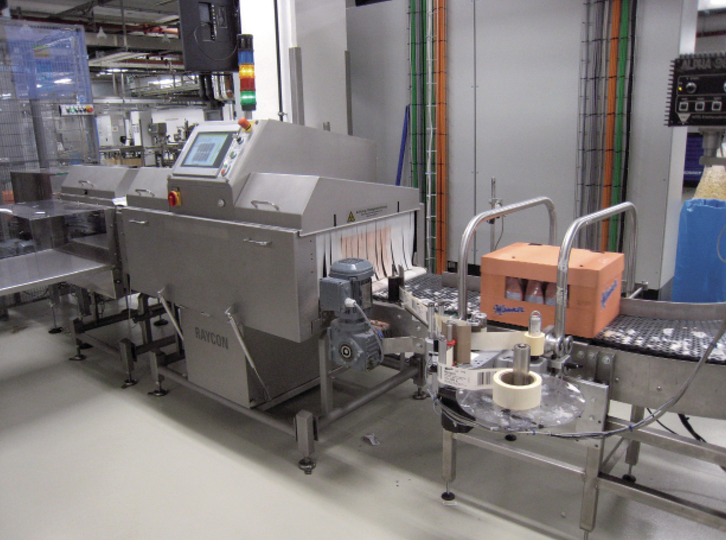

Smart Systems for X-ray Inspection

Our X-ray inspection systems offer a comprehensive solution for detecting foreign bodies and product defects in food. They enable non-invasive inspection and identify various types of contaminants and quality issues. This protects manufacturers from complaints and product recalls, ensuring consumer safety.

READ MORE

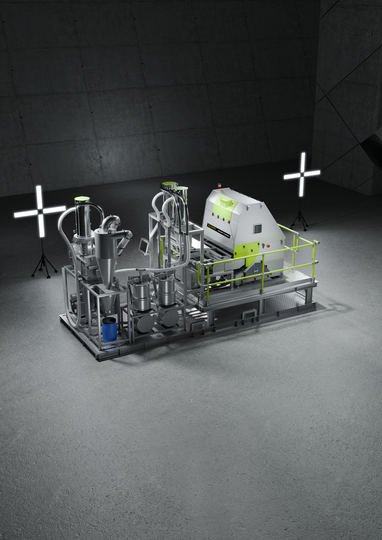

Separation of Magnetic Metals

Our magnetic systems deliver exceptional magnetic performance and efficient design to remove even the finest ferrous metal contaminants. Offset magnetic bars achieve maximum separation efficiency. They are easy and quick to integrate into piping systems, hoppers, or directly at material inlets—even in existing production lines.

READ MORE

ADD-ONS & SERVICES

Smart Add-ons for Enhanced Performance

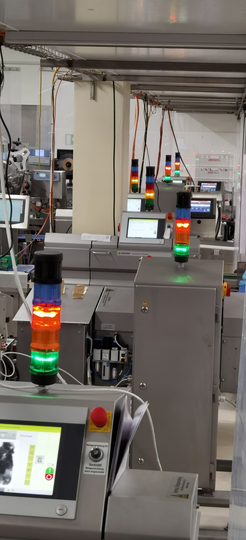

Insight.WEB, the visualization software for metal detectors, -separators and product inspection systems, brings transparency to your production processes, offering a clear overview for enhanced efficiency and increased profitability. Our smart machine monitoring reduces downtime and maximizes your OEE (Overall Equipment Effectiveness).

Centralized Control of

All Sesotec and Third-Party Devices

Clear Visualization & Control

of Your Processes

Maximize Profitability with

Data-Driven Process Optimization

Now Even Smarter: THiNK

Up to

1.500

Products per Minute

Up to

1.4

meters per second

Comprehensive

365

Days of Global Service

Sesotec is a member of the "Save Food" initiative

Sustainable, resource-efficient processes are at the heart of our company philosophy. That's why we're part of the "SAVE FOOD" initiative. Our mission: Delivering solutions for the food industry that reduce food waste while boosting productivity and enhancing product quality.

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.jpg)

.jpg)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.JPG)

.jpeg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.jpg)