100% Quality, 0% Foreign Bodies

Detect foreign bodies in your products? We've got it covered.

Foreign bodies like glass and plastic particles, stones, or metal shavings are unfortunately common in bread and bakery production. Our X-ray inspection, metal detection, and magnet systems help identify and remove them before they reach your products.

We understand how crucial it is for you to meet regulatory standards and avoid recalls, so we develop our products with your practical needs and requirements in mind. For seamless production, premium baked goods, and satisfied customers.

The Most Common Foreign Bodies in the Bakery and Bread Industry

Operator Items

Foreign bodies like pens, hairpins, or gloves must be detected and removed to prevent injuries and contamination.

Metal Wear and Machine Failure

Metal debris and broken machine parts can enter production due to wear, material fatigue, or improper handling, posing health risks.

Little Stones

Detecting and removing small stones from raw materials like grains is essential to protect consumers from harm.

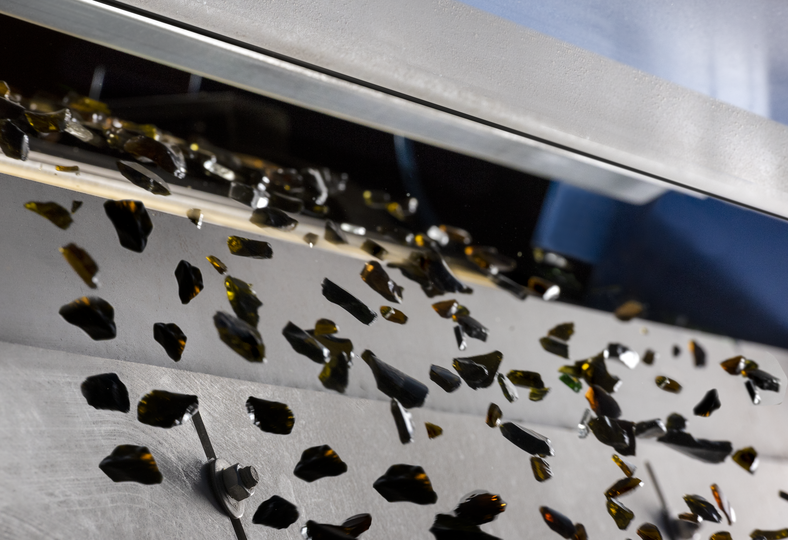

Glass Shards

Identify and remove glass shards from broken lighting or containers to prevent injuries.

Plastic Components

Identify and remove plastic components from packaging or machinery to prevent contamination and allergic reactions.

Operator Items

Foreign bodies like pens, hairpins, or gloves must be detected and removed to prevent injuries and contamination.

Metal Wear and Machine Failure

Metal debris and broken machine parts can enter production due to wear, material fatigue, or improper handling, posing health risks.

Little Stones

Detecting and removing small stones from raw materials like grains is essential to protect consumers from harm.

Glass Shards

Identify and remove glass shards from broken lighting or containers to prevent injuries.

Plastic Components

Identify and remove plastic components from packaging or machinery to prevent contamination and allergic reactions.

No more foreign bodies in your baked goods. Sounds good?

Discover how it works from our experts.

Savor the Joy of Bread and Baking—With Confidence!

- X-ray Inspection

- Metal Detection

- Magnetic Systems

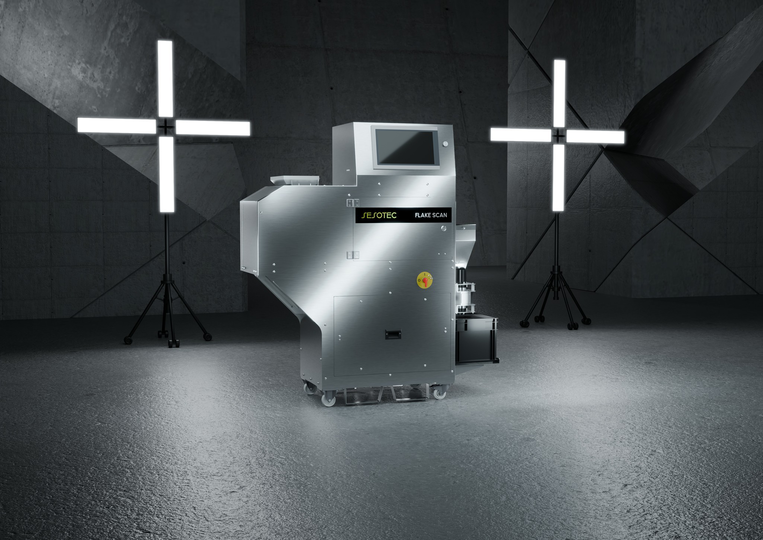

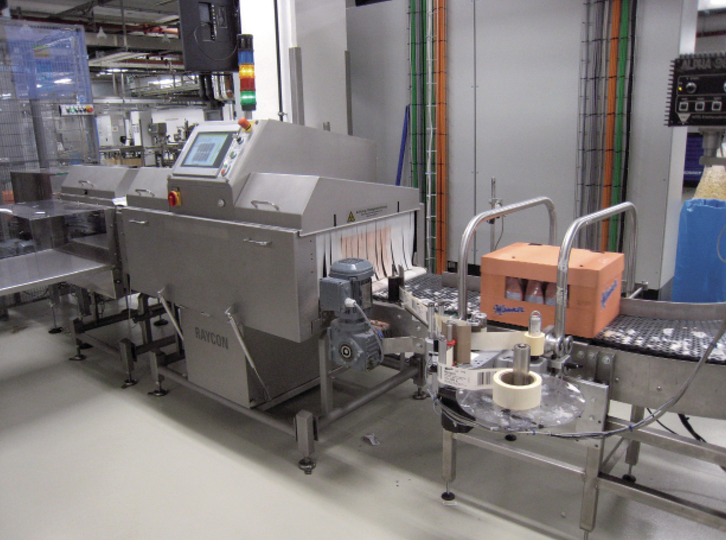

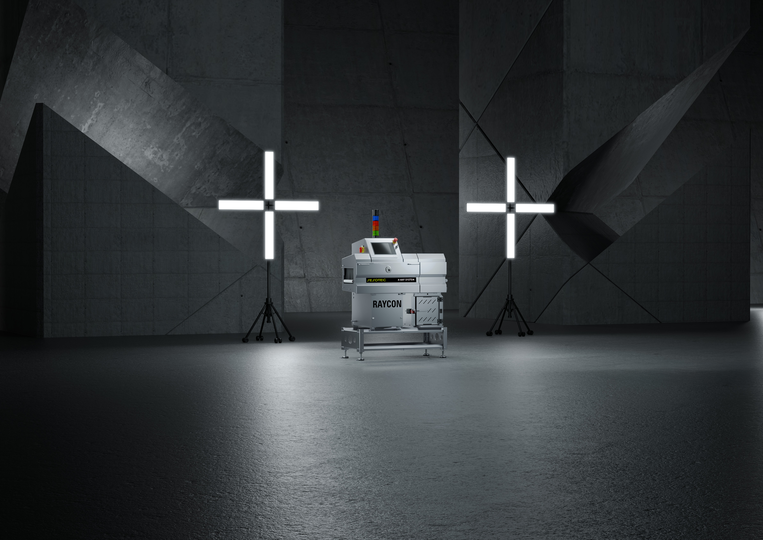

X-ray Inspection

Our X-ray inspection systems ensure the ultra-precise detection of foreign bodies such as metal, glass, or bone in bread and baked goods.

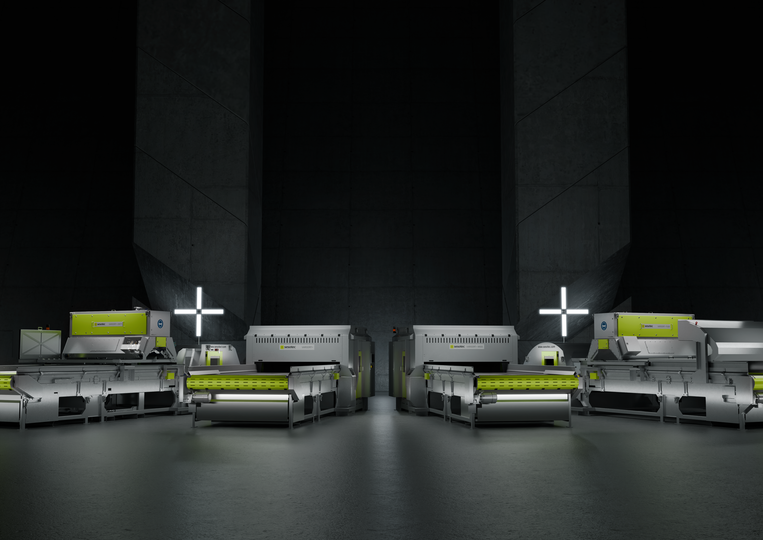

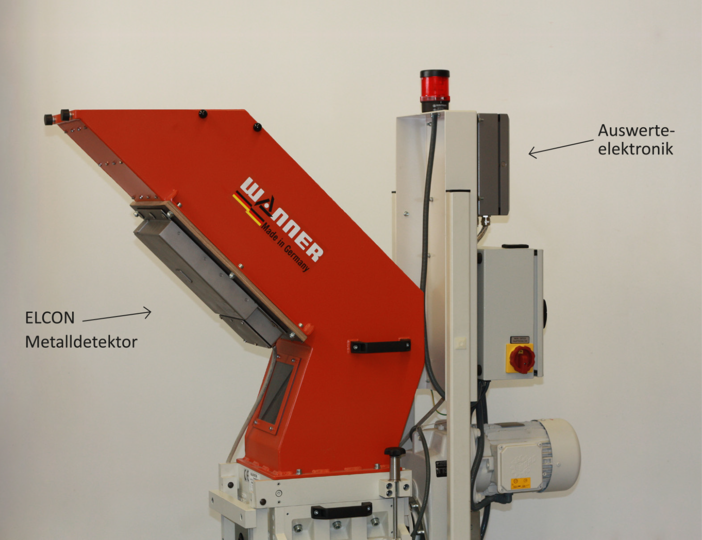

Metal Detection

Sesotec metal detection systems ensure the reliable identification of metallic contaminants in bread and baked goods.

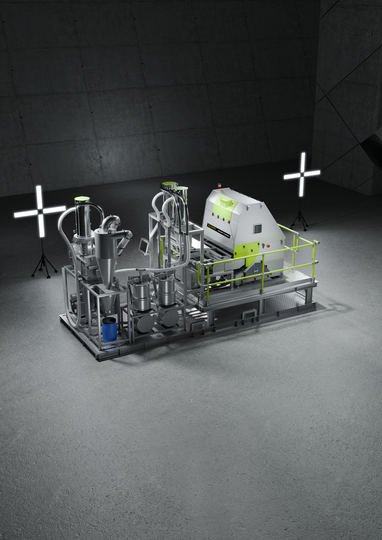

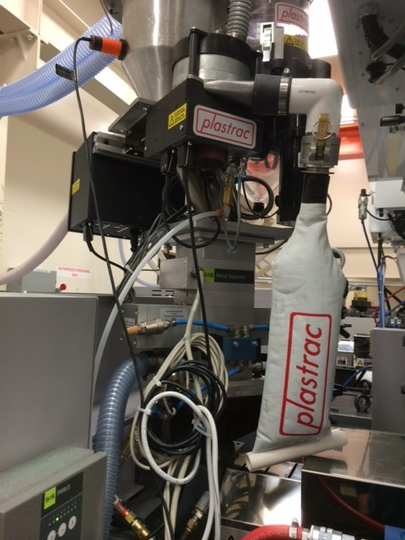

Magnetic Systems

Sesotec's magnetic systems efficiently eliminate metallic contaminants like iron filings from raw materials before processing.

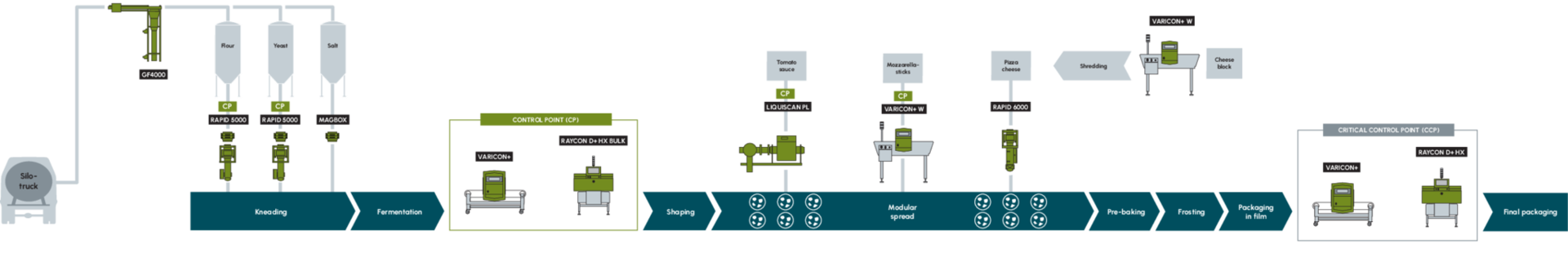

Powerful Solutions for Every Aspect of Bread and Bakery Production

Our modular systems deliver solutions for the entire bread and bakery industry. Whether your business revolves around fresh rolls, cake bases, or frozen pizzas:

With industry-leading detection technology and advanced AI features, Sesotec ensures maximum safety and product quality in your production.

Dough and Dough Pieces

Early foreign body detection in dough and dough pieces prevents contaminants from entering further processing. This ensures unwanted particles are removed from the base mixture.

Frozen Products

In frozen baked goods, foreign body detection prevents the introduction of foreign bodies that would be difficult to identify during further processing. This ensures quality and safety throughout the entire cold chain.

Fresh/Open Products like Bread or Rolls

Foreign body inspection in fresh baked goods minimizes the risk of contaminated products reaching the market. This reduces health risks while enhancing customer trust.

Intermediates

Testing intermediate products (e.g., flour blends, dough) safeguards subsequent production steps and prevents contaminants from spreading further in the process.

Ready-made products like cake bases, pizza dough, toast bread, and more

Consistent foreign body detection in the production of baked goods ensures the quality of the final product and the manufacturer's reputation.

Efficiency and Safety at Every Stage

From goods receipt to production to shipping, our metal detection and X-ray inspection systems ensure top-tier product purity and safe food production at every stage.

Discover the Perfect Sesotec Solution Here

Interested?

ADD-ONS & SERVICES

Smart Add-ons for Enhanced Performance

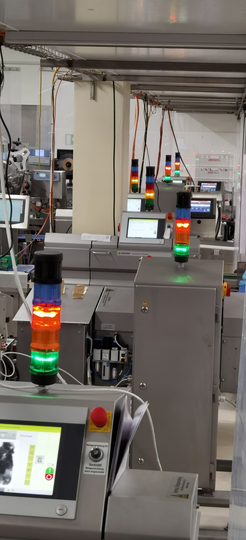

Insight.WEB, the visualization software for metal detectors, -separators and product inspection systems, brings transparency to your production processes, offering a clear overview for enhanced efficiency and increased profitability. Our smart machine monitoring reduces downtime and maximizes your OEE (Overall Equipment Effectiveness).

Centralized Control of

All Sesotec and Third-Party Devices

Clear Visualization & Control

of Your Processes

Maximize Profitability with

Data-Driven Process Optimization

We understand the challenges of the bakery industry

CERTIFICATIONS AND AUDITS

Effective foreign body detection is a crucial quality factor in bread and bakery production, especially regarding certifications and audits. Reliable foreign body detection plays a vital role in maintaining hygiene standards and meeting quality requirements according to international standards like IFS or BRC.

LEGAL REQUIREMENTS

Laws like the EU Regulation 178/2002 and national food laws require the bread and bakery industry to implement effective measures to prevent food contamination with foreign bodies. Failure to comply with these regulations can lead to consequences such as recalls, fines, or the revocation of operating licenses.

CUSTOMER REQUIREMENTS

Customers demand the highest level of product safety and quality when purchasing bread and baked goods. Consumers and trade partners increasingly require guaranteed safety, and even the smallest contaminants can severely damage brand trust.

PROTECT AGAINST RECALLS AND DAMAGES

Large bakeries must minimize all risks of recalls, reputation damage, and legal consequences.

Since implementation, we've significantly reduced foreign body complaints, as even the smallest impurities like stones are filtered out. This is our advantage: Greater safety for us as a company and for our customers.

Read the Case Study

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.jpg)

.jpg)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.JPG)

.jpeg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.jpg)