LIQUID AND PASTY APPLICATIONS

Smart Metal Detection for Liquid Processes

Whether you're producing or processing sausage meat, processed cheese, jam, mustard, or soups, our metal detectors reliably protect machines and consumers from metallic foreign bodies. LIQUISCAN metal detection systems for liquid and pasty products are quickly and easily integrated into existing pipeline systems and are compatible with all standard vacuum fillers, pumps, clipping machines, and sausage filling systems.

Who Benefits from LIQUISCAN Metal Detectors

A metal detector identifies foreign bodies in production, making it essential for quality assurance and compliance with food standards (IFS/HACCP). LIQUISCAN metal detectors are specifically designed for use in pipeline systems with stringent hygiene requirements. They reliably detect and separate metallic contaminants from liquid or viscous products.

Metal detectors for liquid and pasty applications are ideal for food industry manufacturers processing products like sausages and meats, dairy goods, soups and sauces, fish products, pet food, gourmet salads, as well as spreads and pastes.

Metal detectors deliver high detection accuracy for both magnetic and non-magnetic metals—even with strong product effects. Compared to X-ray technology, they are often more cost-effective, require no radiation protection measures, and are easier to integrate into existing production lines.

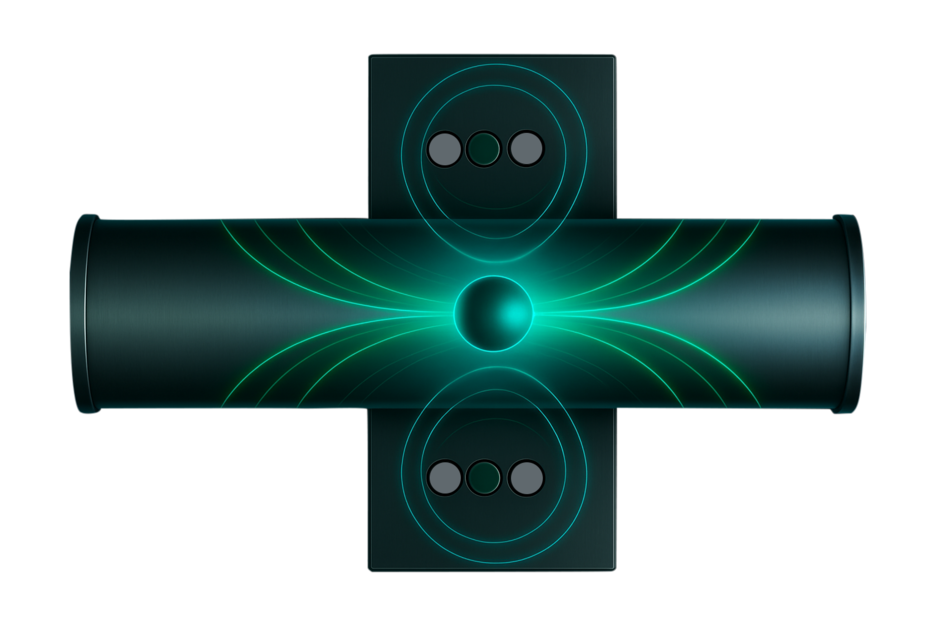

Unmatched sensitivity for all metals – magnetic or not

Effortless Compliance with Top Quality and Hygiene Standards

Unmatched Precision – Even Under High Pressure

Are you interested?

We see what you don't...

- Iron

- Steel

- Stainless Steel

- Non-Ferrous Metals

Common foreign bodies made of iron include machine parts, screws, nails, wires, or wear from conveyor belts and production equipment.

Food products can contain production residues like shavings, screws, or broken tools from mechanical processing.

Stainless steel often enters production through worn or damaged machine parts, pipelines, or cutting tools.

Aluminum, copper, or brass often come from packaging materials, cable scraps, piping, or worn machine parts.

LIQUISCAN in Detail

Stable and Mobile

Stable, height-adjustable stand with rubberized wheels for flexibility and secure support.

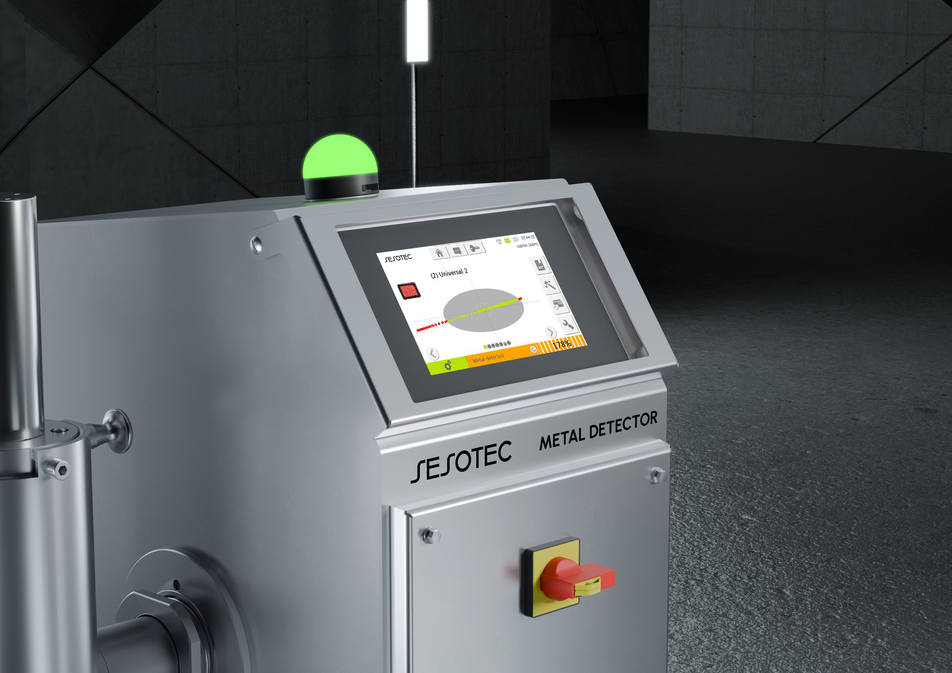

Powerful Control Units

GENIUS ONE Control Unit with single or dual-frequency technology for excellent detection accuracy or INTUITY Control Unit with multi-simultaneous frequency technology for superior detection performance.

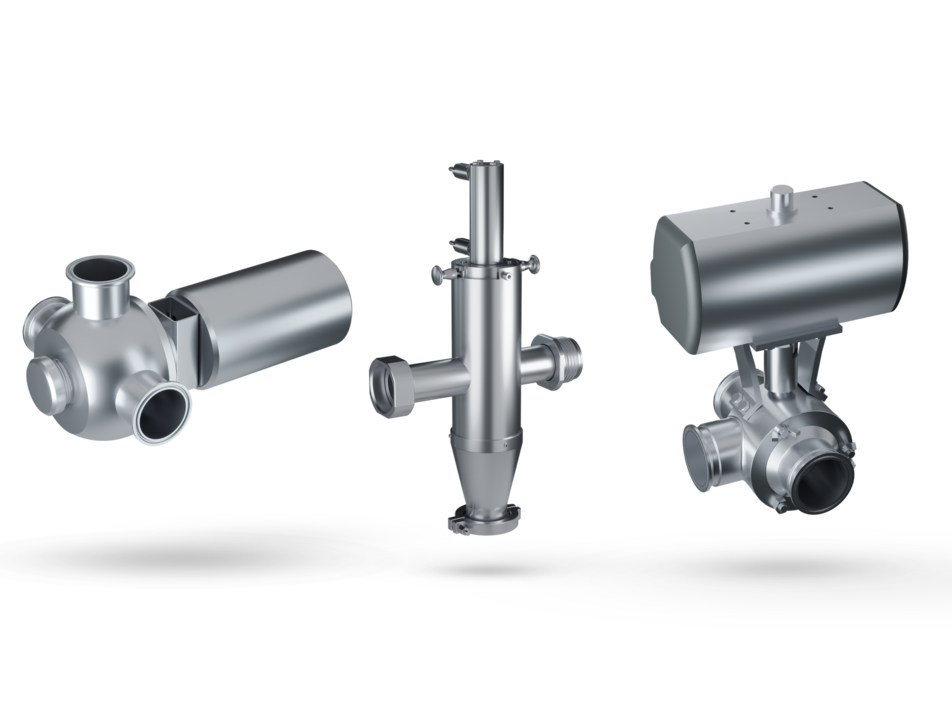

Various Separation Systems

Customizable valves for safe discharge tailored to product consistency

Robust Construction and Durable Design

Durable stainless steel casing for exceptional stability and longevity.

Stable and Mobile

Stable, height-adjustable stand with rubberized wheels for flexibility and secure support.

Powerful Control Units

GENIUS ONE Control Unit with single or dual-frequency technology for excellent detection accuracy or INTUITY Control Unit with multi-simultaneous frequency technology for superior detection performance.

Various Separation Systems

Customizable valves for safe discharge tailored to product consistency

Robust Construction and Durable Design

Durable stainless steel casing for exceptional stability and longevity.

We deliver the perfect solution for every application—standard or customized

Durability through

Quality "Made in Germany"

10 years of parts availability,

rapid service response times

Your Priorities - Our Solutions

- Compliance

- Safety

- Operation

- Hygiene

- Efficiency

- Service

Compliance and Precision

Achieve unmatched detection sensitivity even with strong product effects using single or dual-frequency technology. Combined with the Sesotec Compliance Package, this ensures adherence to legal regulations and quality standards.

Safety for People & Products

Secure metal removal through features like compressed air monitoring and separating unit monitoring ensures consumers receive contamination-free products.

Easy-to-Use Interface

Configure our systems effortlessly for various applications using a 5" or 7" color touch display with intuitive menu navigation. Operating errors are virtually eliminated.

Sophisticated Hygiene Design

Durable and hygienic enclosures ensure effortless cleaning and maintenance.

Efficiency Across All Areas

Reliable removal of metallic contaminants ensures uncontaminated products. Smart sensitivity adjustment and high interference resistance prevent false rejects and boost profitability.

Reliable, Fast Service

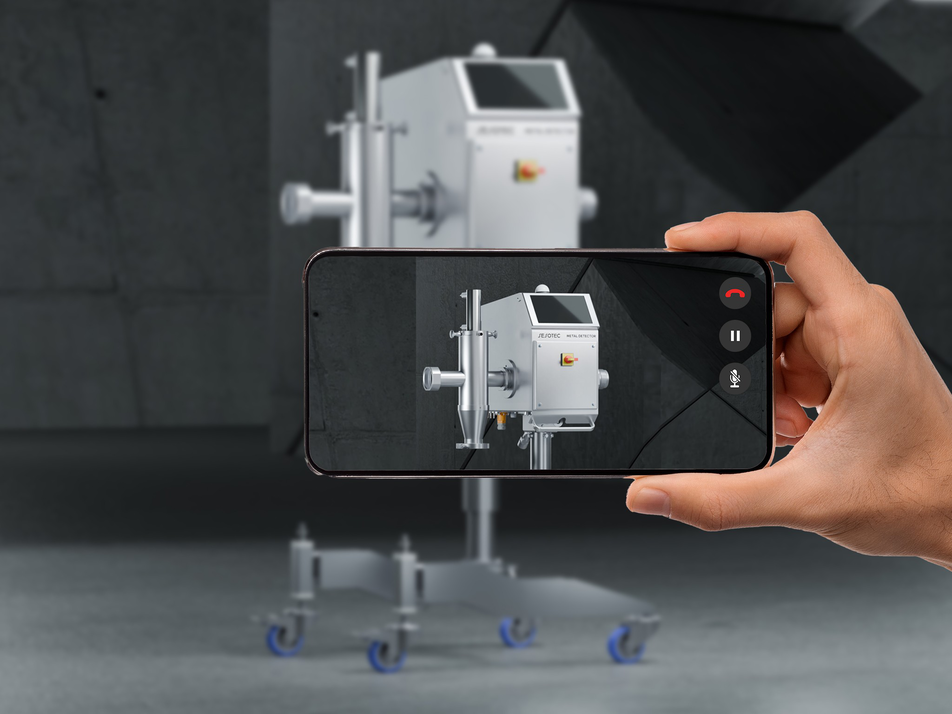

With warranty services, a blend of on-site and remote support, and targeted training, you receive optimal assistance for seamless operations.

0

Stainless Steel in the Product0

Pipe Diameter Sizes0

Product Temperature

Innovative Technology

The integrated detection coil with induction technology ensures optimal metal detection, high mechanical stability, and maximum interference resistance.

Seamless Integration

LIQUISCAN metal detection systems seamlessly integrate into existing pipeline systems and are compatible with all standard vacuum fillers, pumps, clipping machines, and sausage filling systems.

One Product Family – Diverse Solutions

Our Metal Detectors for Liquid and Viscous Applications

Brochure

Download

Discover a comprehensive overview of all technical specifications for our product line designed for liquid and paste applications in our brochure.

ADD-ONS & SERVICES

Smart Add-ons for Enhanced Performance

Insight.WEB, the visualization software for metal detectors, -separators and product inspection systems, brings transparency to your production processes, offering a clear overview for enhanced efficiency and increased profitability. Our smart machine monitoring reduces downtime and maximizes your OEE (Overall Equipment Effectiveness).

Centralized Control of

All Sesotec and Third-Party Devices

Clear Visualization & Control

of Your Processes

Maximize Profitability with

Data-Driven Process Optimization