FEED

Wildly Effective Foreign Body Detection

Feed production is all about crafting the perfect blend of ingredients like meat, vegetables, grains, and hay to create a high-quality final product. However, each ingredient carries its own risk of contamination that can slip unnoticed into the manufacturing process.

The Most Common Foreign Bodies in Feed Production

Metal abrasion from conveyor lines or processing machines

Tiny metal parts that detach from machines and conveyors can unknowingly end up in feed products.

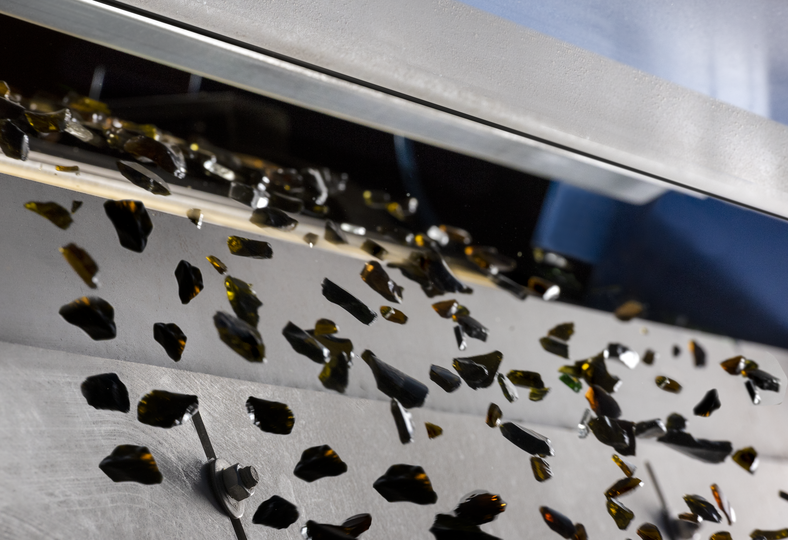

Shattered Glass

Glass shards, such as those from broken containers, pose a significant risk to feed safety.

Plastic Components

Plastics can enter feed through packaging materials, for example.

Machine Failure

When components like metal pieces break off, they can enter the feed and contaminate the product.

Operator Items

Small items can unintentionally enter the feed during production.

Metal abrasion from conveyor lines or processing machines

Tiny metal parts that detach from machines and conveyors can unknowingly end up in feed products.

Shattered Glass

Glass shards, such as those from broken containers, pose a significant risk to feed safety.

Plastic Components

Plastics can enter feed through packaging materials, for example.

Machine Failure

When components like metal pieces break off, they can enter the feed and contaminate the product.

Operator Items

Small items can unintentionally enter the feed during production.

Foreign bodies in your feed?

Three Technologies. For Unmatched Quality.

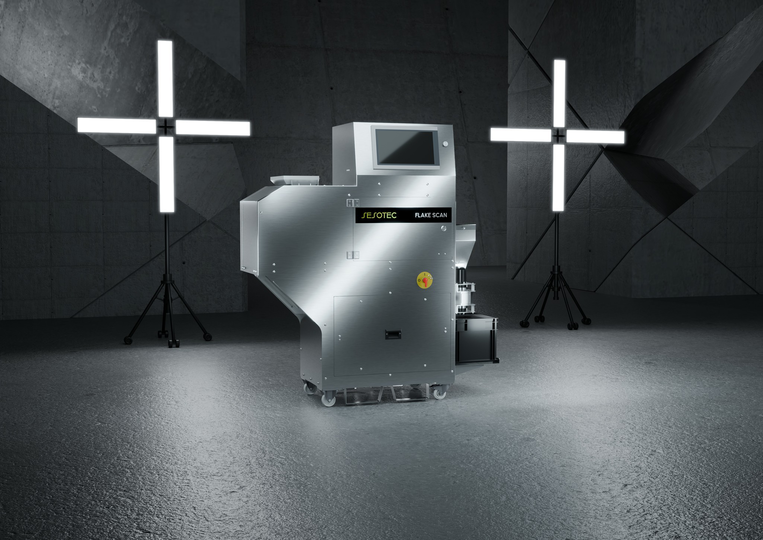

- X-ray Inspection

- Metal Detection

- Magnetic Systems

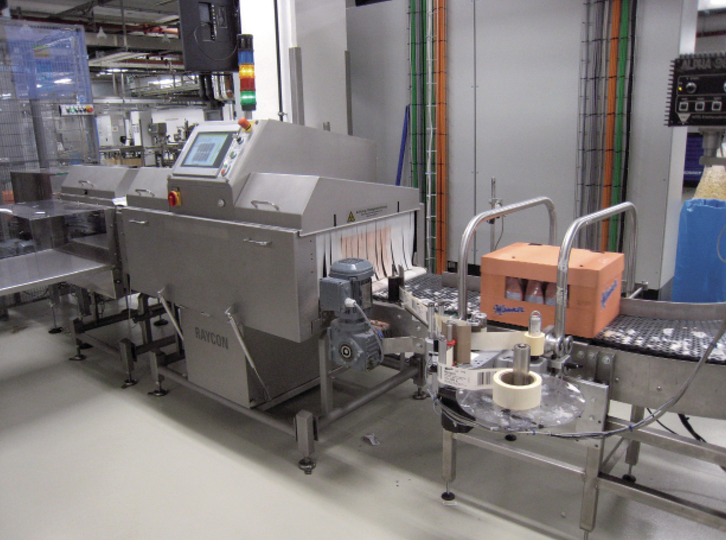

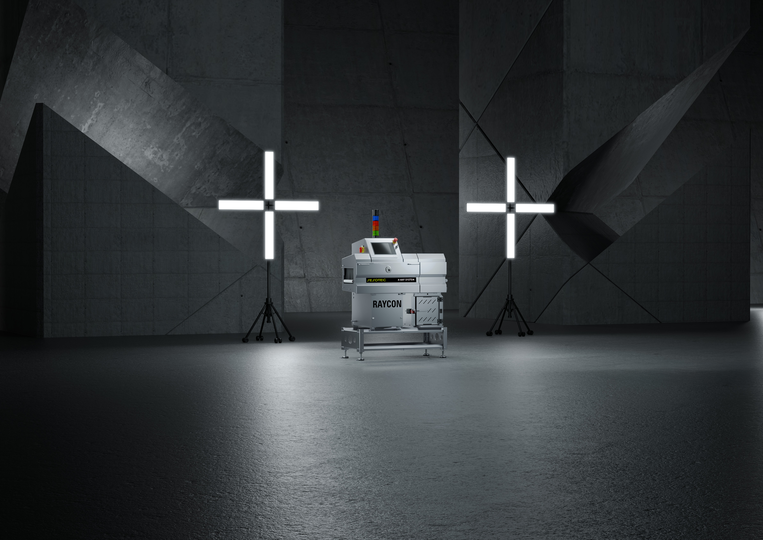

X-ray Inspection

Our X-ray inspection systems ensure the highly precise detection of foreign bodies such as metal, glass, or bone in animal feed.

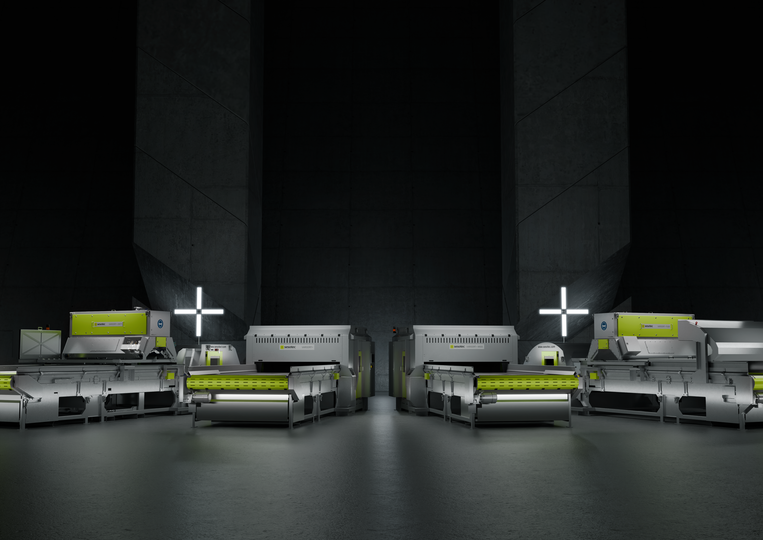

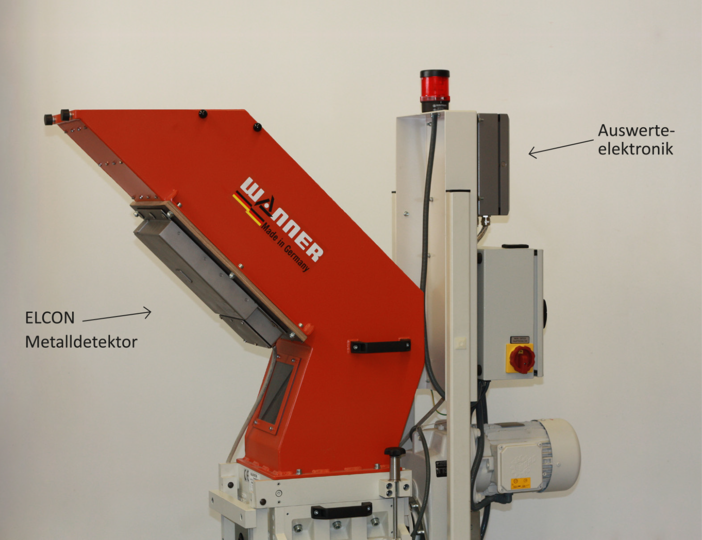

Metal Detection

Sesotec metal detection systems ensure the reliable detection of metallic contaminants in pet food.

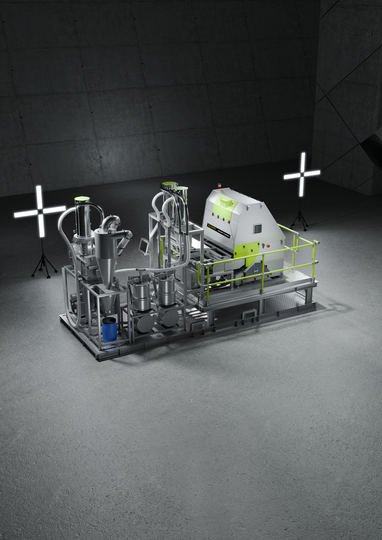

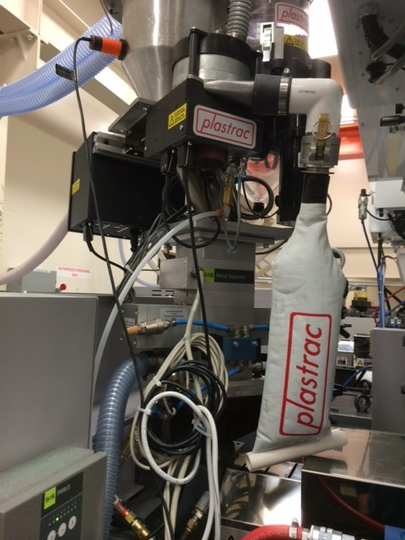

Magnetic Systems

Sesotec's magnetic systems efficiently eliminate metallic contaminants like iron filings from feed materials before further processing.

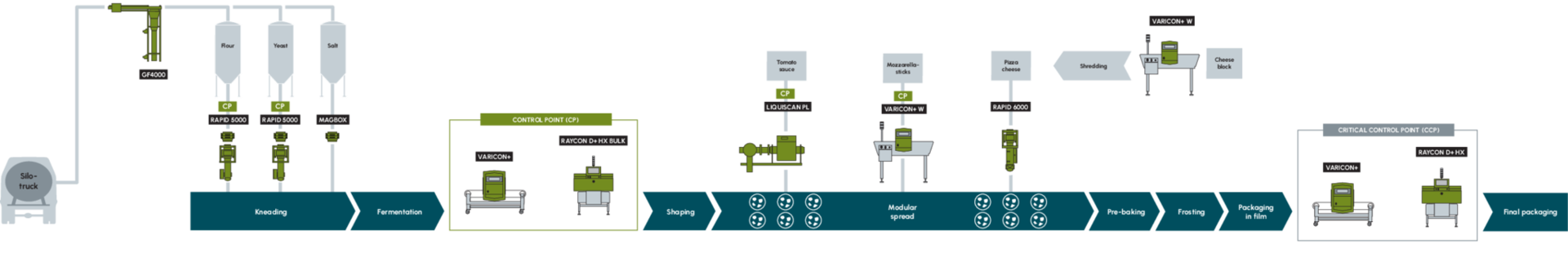

Where do feed manufacturers use our equipment?

In feed production, Sesotec devices are primarily used at the goods income and shipping stage:

Our metal detectors and X-ray systems inspect finished and packaged products for final quality assurance, detecting foreign bodies and removing contaminated packages.

Feed for Livestock

This includes feed for cattle, pigs, sheep, and poultry. These feeds demand rigorous checks as they directly enter the food chain.

Dog and Cat Food

Both dry and wet food for dogs and cats must be inspected for foreign bodies.

Fish Feed

Feed for aquaculture, such as pellets for farmed fish, must be free from foreign bodies.

Bird Feed

In bird feed blends containing various seeds and nutrients, it's crucial to eliminate harmful contaminants.

Across the Entire Production Line

From goods receipt to production to dispatch, our metal detection and X-ray inspection systems ensure top-tier product purity and safe food production at every stage.

Discover the Perfect Sesotec Solution with Ease

Interested?

ADD-ONS & SERVICES

Smart Add-ons for Enhanced Performance

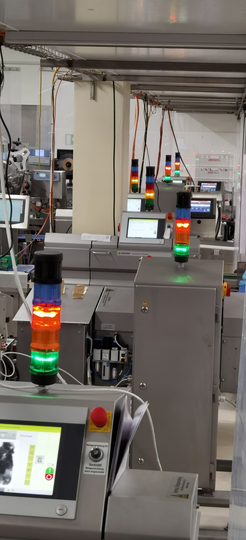

Insight.WEB, the visualization software for metal detectors, -separators and product inspection systems, brings transparency to your production processes, offering a clear overview for enhanced efficiency and increased profitability. Our smart machine monitoring reduces downtime and maximizes your OEE (Overall Equipment Effectiveness).

Centralized Control of

All Sesotec and Third-Party Devices

Clear Visualization & Control

of Your Processes

Maximize Profitability with

Data-Driven Process Optimization

We understand the challenges of feed production.

CERTIFICATIONS AND AUDITS

Effective foreign body detection is a crucial quality factor in the feed industry, especially regarding certifications and audits.

LEGAL REQUIREMENTS

Laws such as the EU Regulation 178/2002 and national feed laws require feed manufacturers to implement effective measures to prevent the contamination of animal feed with foreign bodies.

CUSTOMER REQUIREMENTS

Customers rightly demand the highest level of product safety and quality from feed producers. Even the slightest contamination can permanently damage trust in your brand.

PROTECTION AGAINST RECALLS AND DAMAGES

Feed companies must minimize all risks of recalls, reputation damage, and legal consequences.

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.jpg)

.jpg)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.JPG)

.jpeg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.jpg)