Rubber at Its Best

For manufacturers of vehicle tires and other rubber products, the accidental introduction of metal parts into production can lead to costly consequences. Risks include damage, machine downtime, and the delivery of substandard products. Sesotec's metal detection systems help minimize this risk.

Remove What Doesn't Belong

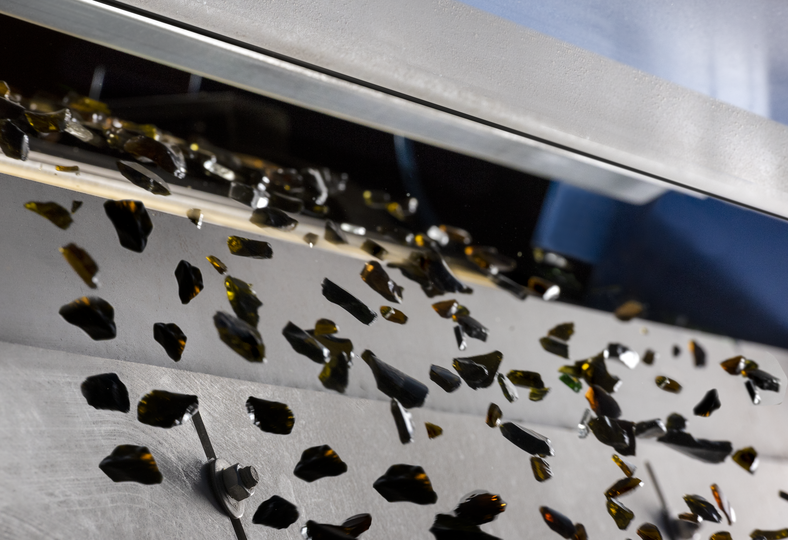

Iron

Metal parts can cause significant damage to extrusion equipment or vulcanizing molds in rubber and tire production, leading to weaknesses in the final product.

Stainless Steel

Stainless steel particles, due to their hardness, can compromise the precision and surface quality of tires or rubber products.

Copper

Copper particles can compromise material stability or cause long-term damage through corrosion.

Aluminum

Aluminum particles can compromise the structural integrity and durability of rubber products and tires.

Brass

Brass disrupts the uniformity of rubber, potentially leading to uneven vulcanization.

Iron

Metal parts can cause significant damage to extrusion equipment or vulcanizing molds in rubber and tire production, leading to weaknesses in the final product.

Stainless Steel

Stainless steel particles, due to their hardness, can compromise the precision and surface quality of tires or rubber products.

Copper

Copper particles can compromise material stability or cause long-term damage through corrosion.

Aluminum

Aluminum particles can compromise the structural integrity and durability of rubber products and tires.

Brass

Brass disrupts the uniformity of rubber, potentially leading to uneven vulcanization.

Having trouble with these or other foreign bodies?

- Metal Detection and Separation

- Magnetic Systems

- Material Management

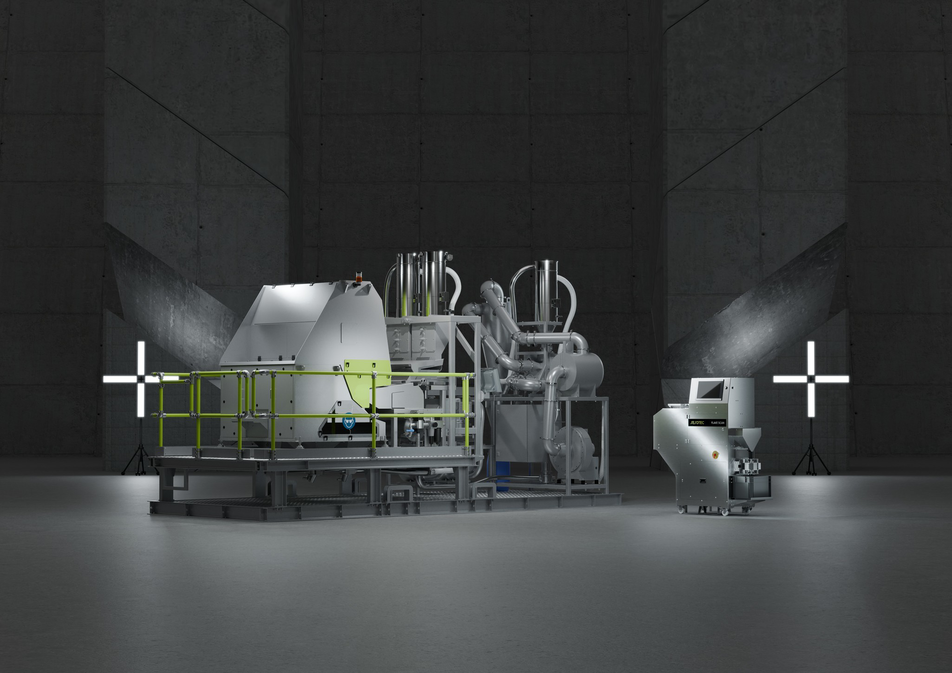

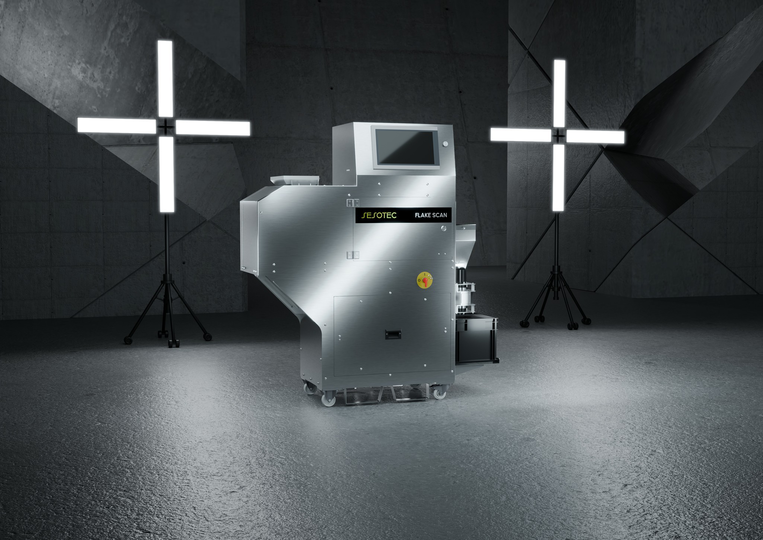

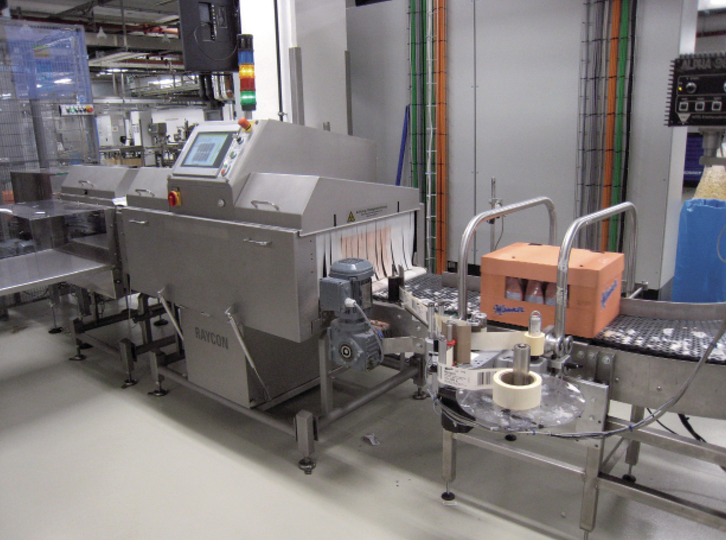

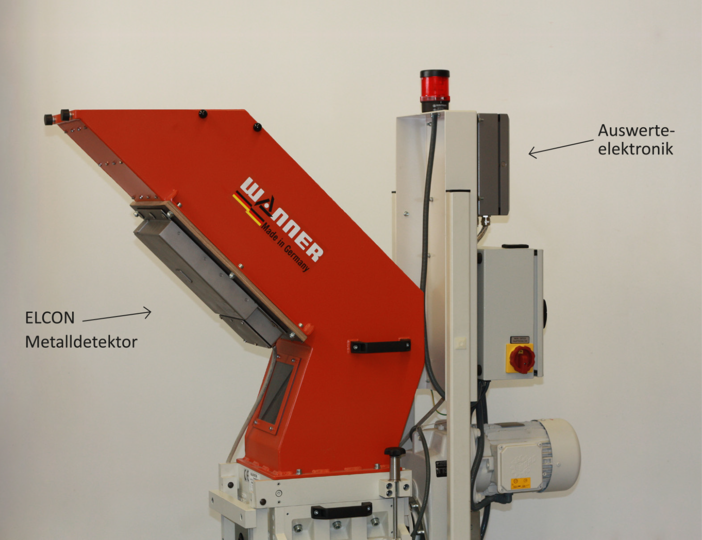

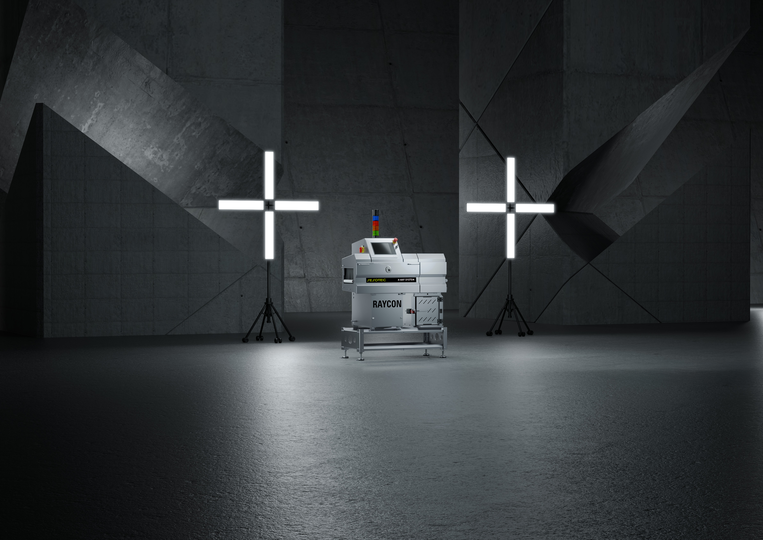

Metal Detection and Separation

Using inductive technology, Sesotec metal detection systems identify all metallic foreign bodies in rubber and tire production.

Magnetic Systems

Sesotec magnetic systems deliver exceptional magnetic performance and efficient design to eliminate even the finest ferrous metal contaminants.

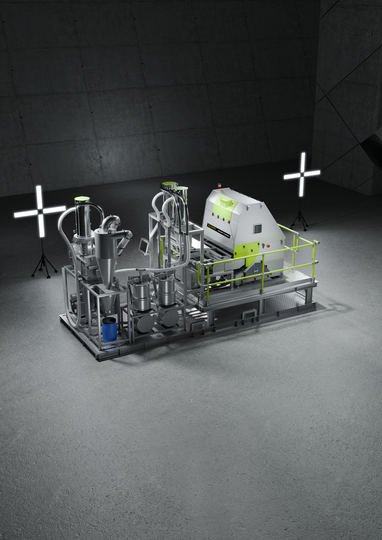

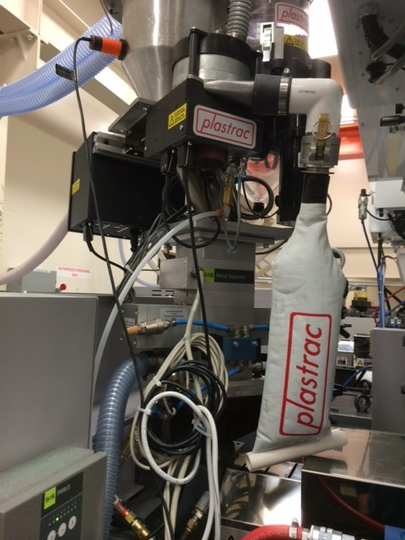

Material Management

FLAKE SCAN and PRE-SORT systems ensure top-tier material quality for plastic processors.

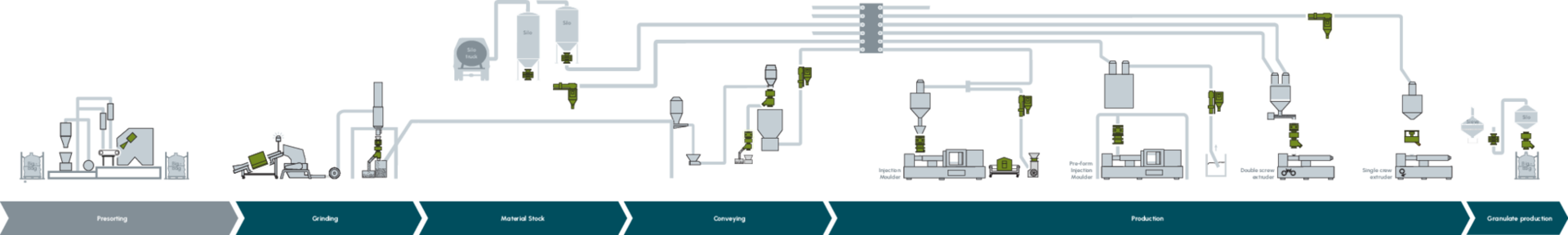

Where are Sesotec solutions used in the rubber and tire industry?

Common applications include incoming goods inspection of rubber and additives, examining rubber sheets on conveyor belts (before feeding into extruders and calenders), and final quality control of finished products before packaging.

Vehicle Tires

Foreign body detection ensures that no contaminants compromise the safety and durability of the tires.

Rubber

Detecting foreign bodies ensures the purity of rubber and prevents quality defects in the final product.

Seals

Foreign body detection ensures that seals meet their requirements for functionality and sealing power without compromise.

Hoses

Impurities are eliminated to ensure the flexibility and pressure resistance of rubber hoses.

Conveyor Belts

Detection prevents foreign bodies from compromising the stability and durability of rubber conveyor belts.

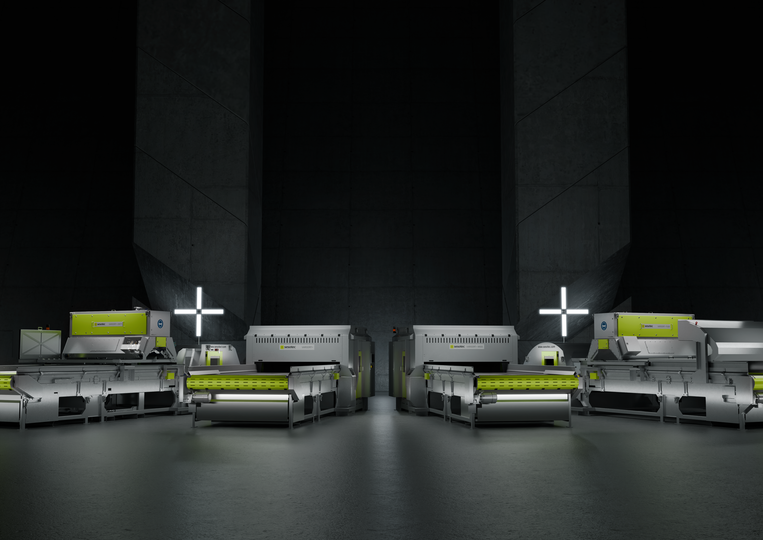

Across the Entire Production Line

Maximum security for your entire production: Our metal detection and magnet systems identify and remove foreign bodies throughout the production line. This keeps processes stable, products compliant, and your productivity high—from material input to the finished product.

Discover the Perfect Sesotec Solution Here

Are You Interested?

ADD-ONS & SERVICES

Smart Add-ons for Enhanced Performance

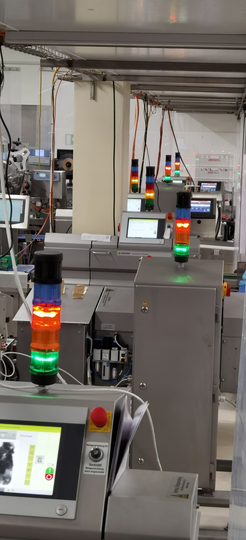

Insight.WEB, the visualization software for metal detectors, -separators and product inspection systems, brings transparency to your production processes, offering a clear overview for enhanced efficiency and increased profitability. Our smart machine monitoring reduces downtime and maximizes your OEE (Overall Equipment Effectiveness).

Centralized Control of

All Sesotec and Third-Party Devices

Clear Visualization & Control

of Your Processes

Maximize Profitability with

Data-Driven Process Optimization

We understand the challenges of the rubber and tire industry.

Overall Equipment Effectiveness

Foreign bodies in production can lead to unexpected delays, increased maintenance, and reduced output.

Customer Demands and Quality

The rubber and tire industry is under pressure to deliver products of the highest purity and quality. Foreign bodies in the final product jeopardize customer satisfaction and can lead to complaints or loss of orders.

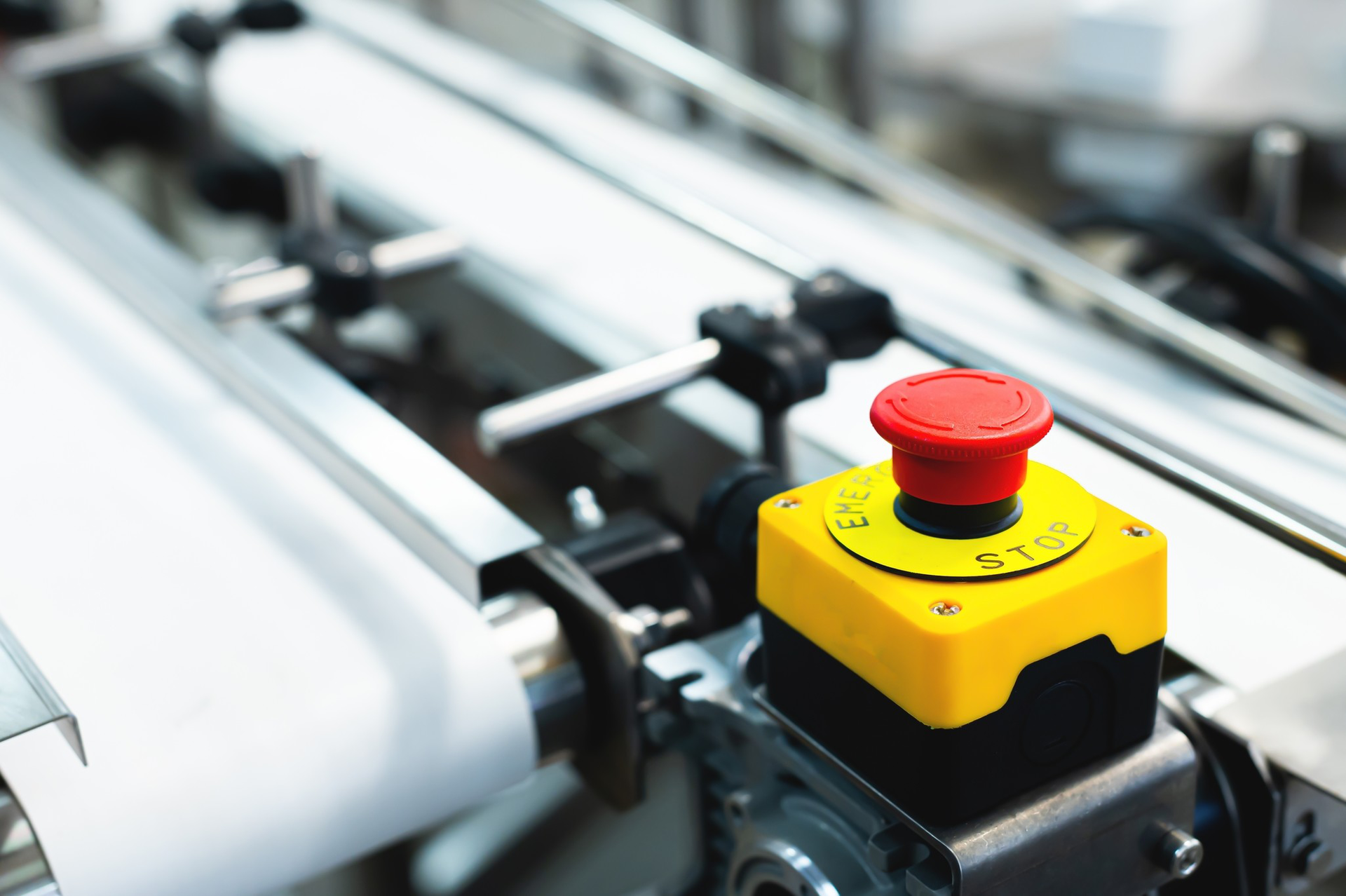

Prevent Production Downtime

Even small foreign bodies can halt production processes, leading to costly downtime and, in the worst case, the loss of entire batches.

Protect Against Machine Damage

Foreign bodies like metal parts or debris can damage sensitive production machinery. The result: high repair costs and production delays.

Sesotec metal detectors play a crucial role in making our tire production facilities among the best in the world

VIEW CASE STUDIES

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.jpg)

.jpg)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.JPG)

.jpeg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.jpg)