Processes in Focus. Quality in Control.

Efficient processing and top-tier product quality demand more than just powerful hardware—they require intelligent software. Our software solutions for visualization and control of foreign body detection and sorting systems give you complete command over your production lines.

Process data is transparently displayed, system statuses are monitored in real-time, and all essential information for quality assurance is consolidated. At the same time, intuitive control functions allow for targeted interventions—ensuring smooth operations, minimized downtime, and maximum efficiency.

Anytime, anywhere -

remote or browser-based access

Upload feature for

your own product images

Regular updates for

maximum security

Visualization Solutions

Control Software

Our device control software empowers you to smartly operate our equipment while delivering enhanced performance for your systems.

COMPLETE TRANSPARENCY

Analytics & Visualization

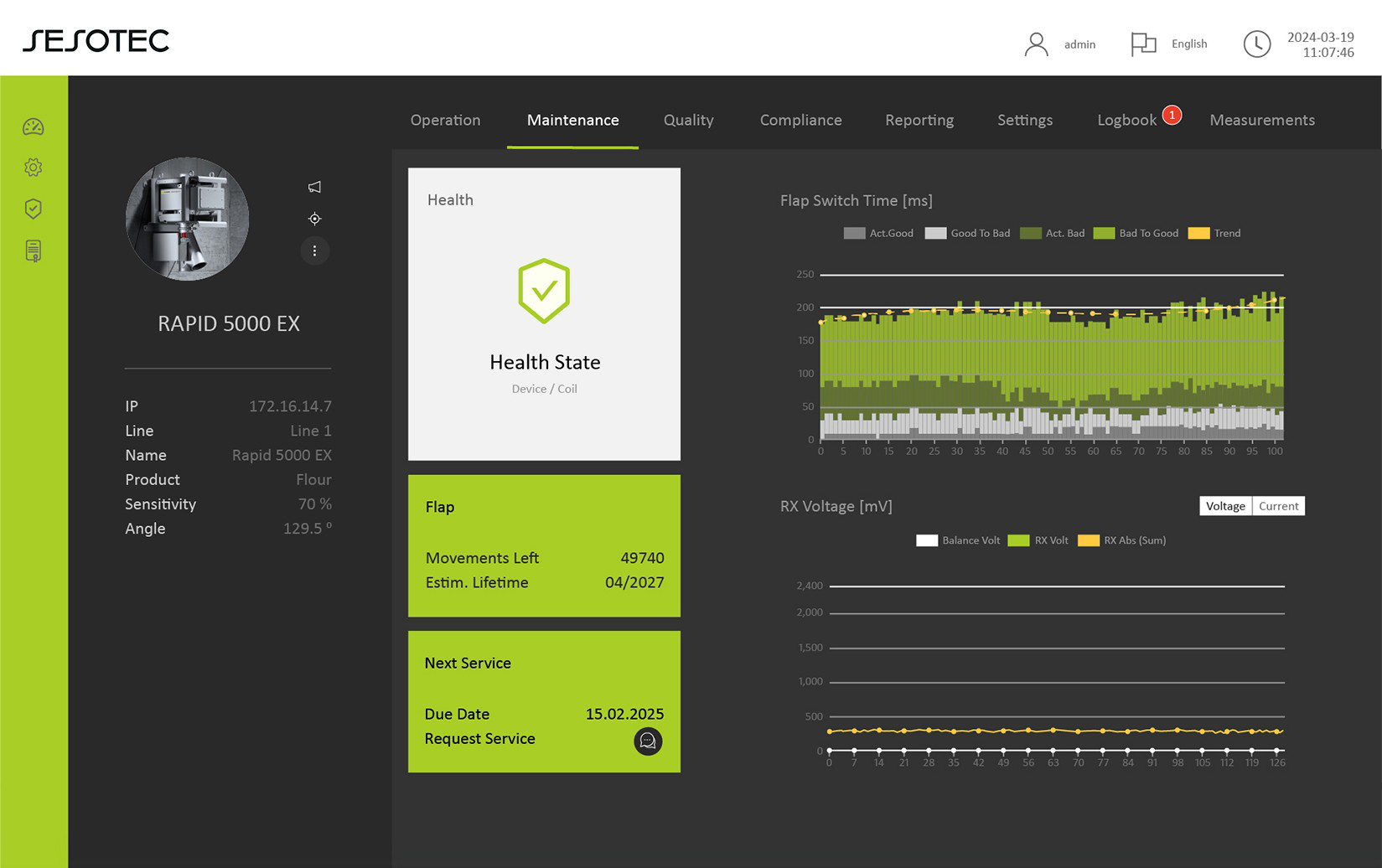

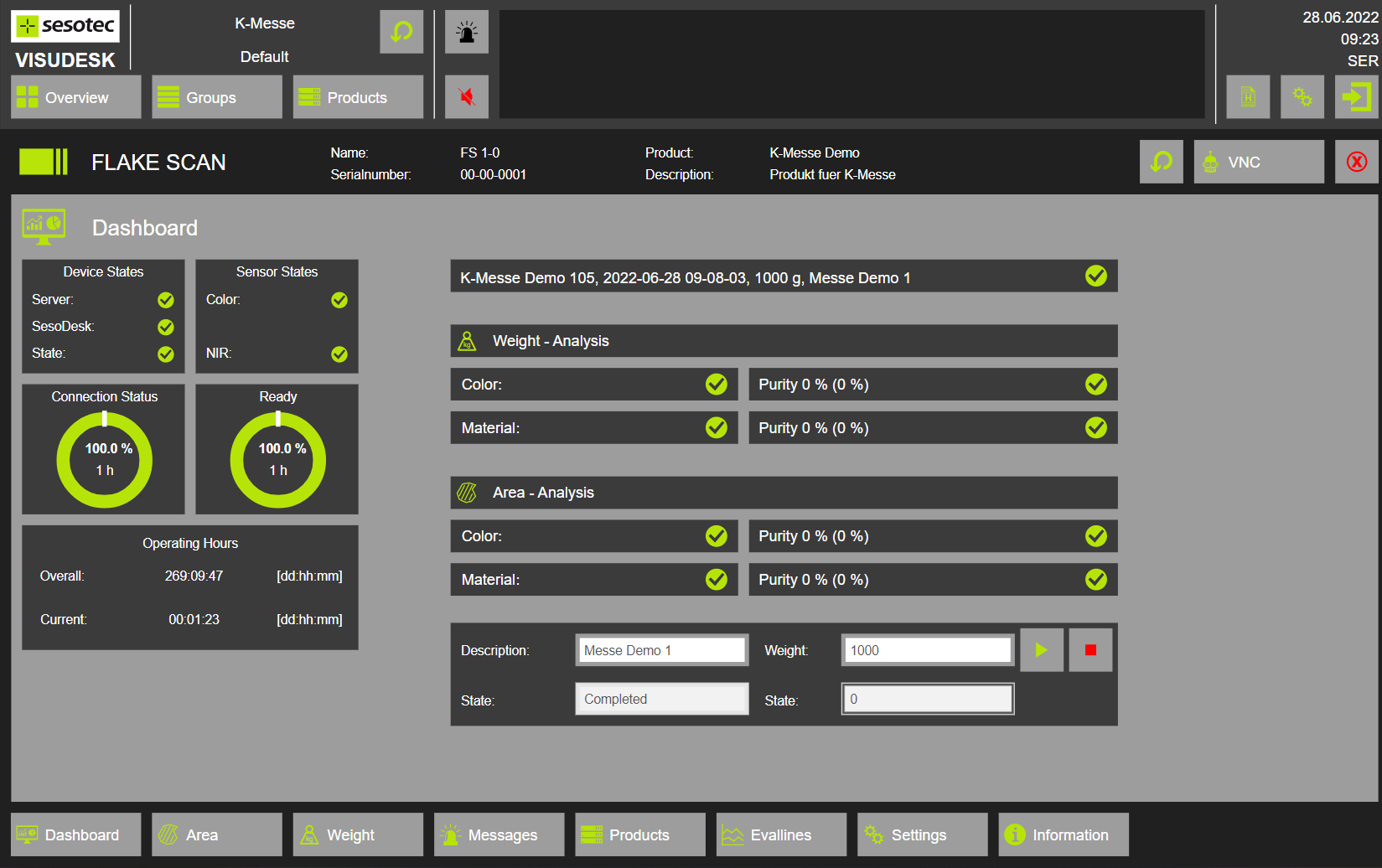

Insight.WEB and VISUDESK bring your Sesotec device data to life: Tailored dashboards transform complex information into clear, actionable visuals. Capture and document key production milestones with comprehensive PDF reports.

- Production efficiency analysis

- Effortless optimization of various influencing factors

- Comprehensive overview of device parameters like temperature and transmitter/receiver voltage

- Logbook with comment feature

- Customizable filters and view settings

Insight.WEB

Software for Product Inspection Systems

VISUDESK

Software for Sorting and Analysis Systems

Your Benefits

- Effortless and rapid process optimization

- Data-driven decisions for ongoing improvement

- Facilitates cross-line benchmarking

- Enables preventive maintenance and minimizes downtime

- Browser-based dashboard for easy access via desktop, tablet, or smartphone

- Centralized monitoring, visualization, and control of processing operations

- Valuable reports and statistics to boost product quality and enhance process efficiency

- Clear overview of entire production lines

- Integrate Sesotec metal detectors, separators, X-ray devices, sorting systems, and third-party equipment with OPC UA

- Effortless dashboard design and automatic product changeovers

- Secure data communication via OPC UA protocol

- Expert support from Sesotec technicians for process optimization when needed

Insight.WEB - Software as a Service

SMART DEVICE CONTROL

Control Software

Insight.HMI, our user-centric control software, transforms every production line from the first setup—making it more efficient, effective, simpler, and ultimately safer. With operators in mind, control is managed through widget modules that provide all key information at a glance—soon to be enhanced with intuitive shortcuts for additional settings. Graphic displays enable quick and intuitive understanding of device and production performance.

Excellence

Tailored Solutions

Performance

Take Charge from Anywhere

Insight.HMI takes device operation to an entirely new level. Gone are the days when adjustments and analyses had to be performed and viewed directly on the device in the line. Simply connect the Control Unit and mobile device to the same network, scan the QR code on the device, and the display is fully accessible on your mobile device. Anytime. Anywhere.

7'' Color Touch Display

The expansive screen size fulfills every desire for cutting-edge design. Its premium surface ensures reliable device cleaning in any production environment.

Compliance Package

Always Compliant. Always Safe. The Compliance Package is our solution for seamless and efficient documentation in food production – featuring Audit-Check, Sensitivity Prediction, Compliance Mode, Integrated Compliance Monitoring, and Integrated Validation Process.