Ideas that Shape the Future

For us, innovation means thinking one step ahead. Every development—past, present, or future—reflects our commitment to elevating quality, efficiency, and sustainability to new heights.

Ideas become solutions that build trust and transform entire processes. Our innovations are not just for their own sake; they are a promise: We make the difference that empowers our customers and partners to succeed—today and in the future.

Innovations by Sesotec

What Sets Us Apart

Artificial Intelligence

THiNK and SUSTAiN – our AI technologies for maximum efficiency and sustainability in foreign body detection and material sorting.

Compliance Package

The Compliance Package is our solution for seamless and efficient documentation in food production

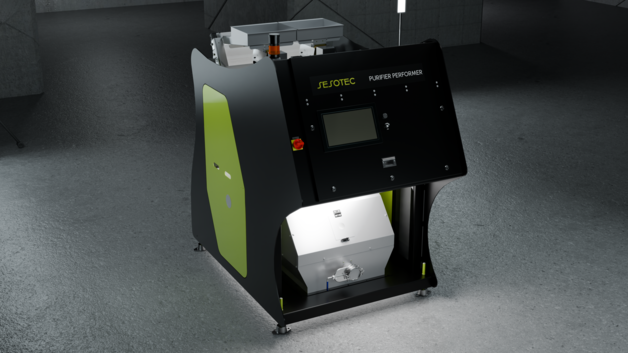

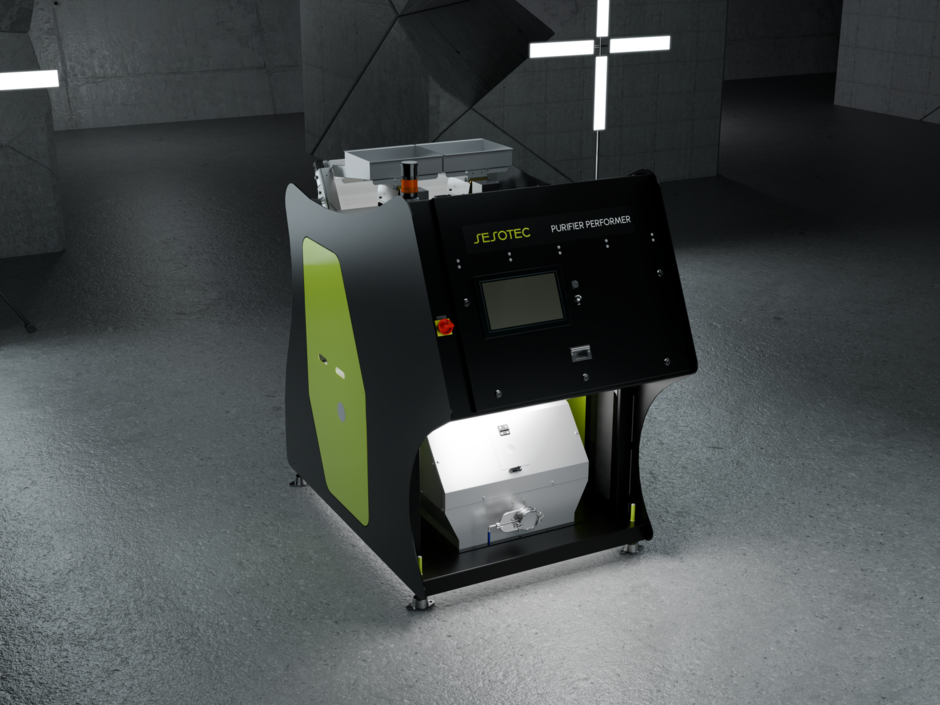

PURIFIER PERFORMER

The new PURIFIER PERFORMER is our latest sorting system for plastic flakes. With dual-sided inspection, it reliably detects even opaque materials, labels, prints, or attachments.

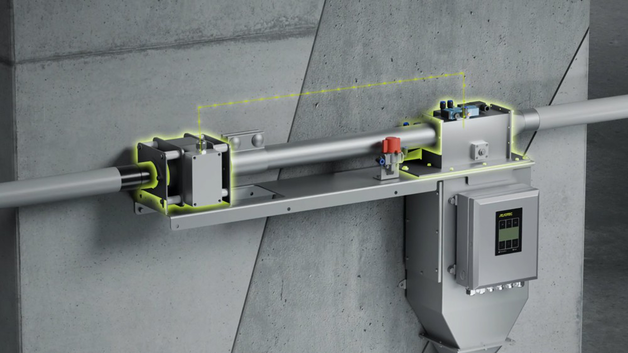

Monitoring.Package

The new "Monitoring.Package" for PROTECTOR metal separators tackles challenges like fluctuating product quality, diverse input materials, and complex process parameters.

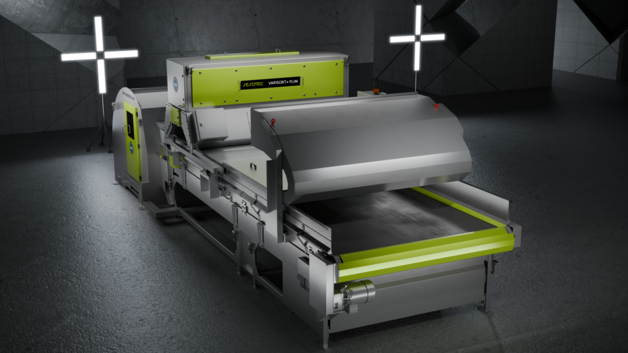

VARISORT+ FILM

The unique feature of the VARISORT+ FILM is its specially designed laminar airflow, ensuring optimal handling of flexible packaging and films.

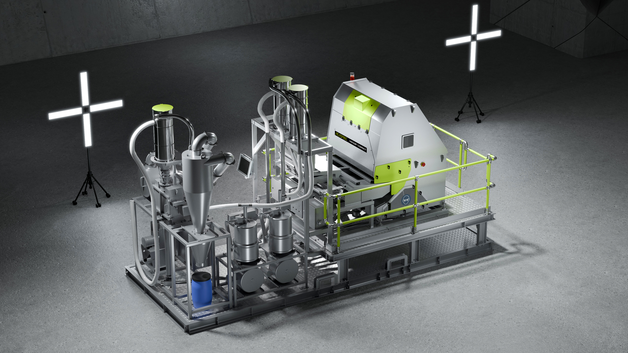

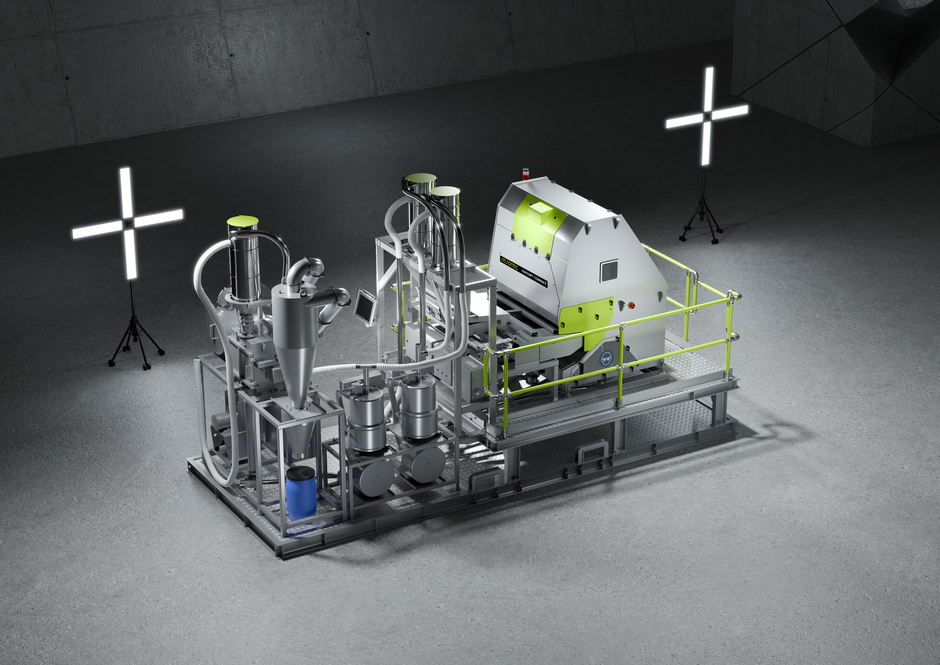

PRE-SORT

With our mobile multisensor sorting platform PRE-SORT, plastic processors have full control over the quality of their regrind.

Insight.HMI

Insight.HMI user-centric interface software transforms every production line to be more efficient, effective, intuitive, and secure.

INTUITY NEX

The new INTUITY NEX represents a coil concept for tunnel metal detectors with an optimized housing design, meeting the highest hygiene standards and complying with IP 66/69K protection ratings.

Speed.Tracking

Revolutionary sensor technology and data analysis—integrated into the GF metal separator—now enable Speed.Tracking for the first time.

The best way to predict the future is to invent it.

Artificial Intelligence

Our adaptive AI software THiNK virtually eliminates the product effect, enabling the effective detection of even the smallest foreign bodies.

Sesotec SUSTAiN Technologies set new standards for intelligent sorting and recycling solutions for the circular economy. NIR-Ai and OBJECT-Ai open up new opportunities for the global recycling industry.

Compliance Package

We ensure you sleep soundly at night with our Sesotec Compliance Package—a comprehensive solution for food safety. Not only do we guarantee regulatory-compliant food production, but you also benefit from secure processes when launching new products. Ensure your machines operate flawlessly at all times, reduce product waste, and stay protected from tampering with paperless in-machine documentation.

PURIFIER PERFORMER

Our new PURIFIER PERFORMER sorting system for plastic flakes sets the standard for efficiency and precision:

With dual-sided inspection, even opaque materials, labels, prints, or attachments are reliably detected. Enhanced C- & NIR resolution allows for the detection of the smallest impurities—ensuring minimal loss and maximum purity. Offering customizable sensor combinations (C, N), working widths from 768mm to 3072mm, and throughput rates from 2.3 to 9.0 t/h, the system provides ultimate flexibility for diverse applications.

Monitoring Package

The Monitoring.Package is an optional sensor unit that attaches directly to injection molding machines and extruders, capturing parameters like moisture, temperature, and color variations of the processed material. This allows deviations to be reported to higher-level systems, enabling process adjustments to ensure top-tier product quality. The Monitoring.Package offers swift integration into the production line, minimizes plastic waste, and maintains a consistent melt point of the material. Additionally, it reduces the energy required for the melting process, promoting environmental sustainability and boosting profitability.

VARISORT+ FILM

The standout feature of the VARISORT+ FILM is its specially designed laminar airflow, ensuring optimal handling of flexible packaging and films.

Materials are stabilized for precise detection and sorting. Another innovative aspect of the VARISORT+ FILM is its aerodynamically constructed ejection housing, which prevents air turbulence that typically hampers sorting efficiency, guaranteeing effective sorting.

PRE-SORT

Achieve sustainable and reliable production with external materials by ensuring product purity from the start. Our mobile multisensor sorting platform, PRE-SORT, empowers plastic processors to control the quality of their regrind. This compact, all-in-one system automatically identifies and separates different types of plastics, colors, and metals from regrinds of varying qualities—fully automated and tailored to your production line needs.

INSIGHT.HMI

Insight.HMI is user-centric control software that optimizes every production line from the initial setup, making it more efficient, effective, and ultimately safer. With the machine operator in mind, control is managed through widget modules that provide all essential information at a glance—soon to be enhanced with intuitive shortcuts for additional settings.

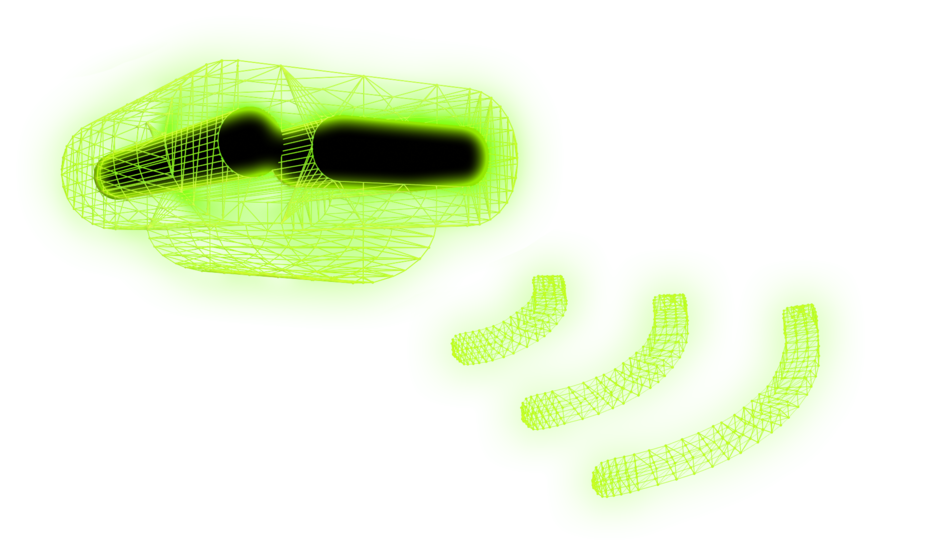

INTUITY NEX

The new INTUITY NEX represents a coil concept for tunnel metal detectors with an optimized housing design that meets the highest hygiene standards and complies with IP 66/69K protection ratings. Combined with the new capacitive touchscreen and the intuitive Insight.HMI user interface, it offers an exceptionally user-friendly, future-ready system: Featuring gesture control and remote visualization. The new Multisimultaneous Quattro Frequency Technology with four parallel operating search frequencies, along with the advanced AI-based THiNK technology, ensures even higher detection accuracy.

Speed.Tracking

The airflow speed within the closed pipe system is known. But how can you determine the actual product speed to optimize the production process and minimize the incorrect ejection of good material? It's simple with the innovative sensors and data acquisition of the GF.

Technological Milestones in Our Company History

AI Innovations NIR-Ai and OBJECT-Ai

Sesotec enhances its technology portfolio with AI-driven solutions NIR-Ai and OBJECT-Ai. These innovations significantly boost sorting accuracy and automation, marking a crucial step towards intelligent, self-learning systems.

PRE-SORT Sorting Platform

With PRE-SORT, Sesotec introduces a powerful sorting platform that significantly boosts efficiency and material quality in plastics processing. Its modular technology allows for flexible adaptations to various applications, enhancing cost-effectiveness in the recycling process.

FLAKE SCAN Material Analysis System

Sesotec introduces FLAKE SCAN, an innovative analysis system for plastic flakes. This technology delivers fast, precise, and reproducible results, setting new standards in quality assurance.

THiNK AI Technology

Introducing THiNK by Sesotec: a groundbreaking concept for intelligent inspection and sorting solutions. This platform integrates cutting-edge sensors, connectivity, and AI-driven features to ensure maximum efficiency and process reliability.

INTUITY sets new standards

The newly developed INTUITY metal detector by Sesotec sets new standards for unparalleled detection accuracy. At the same time, the system impresses with its intuitive operation and seamless integration into production processes.

Food Sorting

Sesotec introduces CAPTURA FLOW, an innovative sorting system for the food industry. This technology ensures exceptionally precise detection and removal of unwanted contaminants directly in the product stream.

FLAKE PURIFIER Plastic Sorter

S+S introduces the FLAKE PURIFIER sorting system, setting new standards in plastic recycling. This technology merges precise sensor technology with high throughput for optimal material purity.

Multisensory Solutions for Enhanced Efficiency

Introducing the VARISORT COMPACT: S+S's powerful multi-sensor sorting system. Its compact design allows for seamless integration into recycling processes, ensuring unparalleled sorting precision.

X-ray Technology Now in Our Portfolio

S+S expands its metal detector range with the RAYCON X-ray scanner, unlocking new possibilities in foreign body detection. At the same time, the introduction of the PRIMUS Control Unit offers a modern control system that can be flexibly combined with detectors and separators for the first time.

DSP Technology Becomes the Standard

S+S sets the DSP technology as the standard for all control units, ushering in a new era of high-precision, reliable, and fast metal detection across diverse industries.

Detection with GENIUS

With the launch of GENIUS metal detection technology, S+S introduces a new generation of powerful controls. This technology delivers exceptional sensitivity, adaptable solutions for diverse applications, and an intuitive user experience.

SMD 2 and SENSITY

S+S introduces cutting-edge metal detection technologies with SMD 2 and SENSITY, setting new standards in detection accuracy. These systems enable exceptionally precise detection of even the smallest metal contaminants.

DSP Signal Processing

With the Control Unit SMD 1, S+S introduces a DSP-controlled system for metal detectors and separators. This technology ensures maximum sensitivity and reliability in the packaging, food, chemical, and pharmaceutical industries.

Microprocessor-Controlled Metal Detectors

S+S introduces the first microprocessor-controlled metal detectors and separators for the food and packaging industry. This innovation allows for more precise detection and significantly enhances safety across production lines.

Revolutionary Recycling Innovation

With the MAG 4100 metal separator, S+S introduces a globally patented solution for the glass and wood recycling industries. This innovation sets new standards in the efficient detection and removal of metal contaminants.

Digital Electronics Sets the Standard

S+S is the first manufacturer to introduce digital electronics for industrial detectors and separators, revolutionizing sensor technology. At the same time, metal detectors specifically designed for the textile industry are developed and deployed for the first time.

Pioneering Glass Recycling

With the introduction of the first metal separators for the glass recycling industry, S+S opens up a new field of application. This innovation establishes the foundation for becoming a technology leader in sorting and separation solutions.

The First RAPID Series

With the launch of the first RAPID series, S+S sets the foundation for groundbreaking metal separation solutions. This innovation paves the way for the company's leadership in the plastics industry.