METAL SEPARATION IN FREE-FALL CONVEYOR LINES

Efficient Metal Detection for Bulk Materials

Chunky, powdery, fine, or coarse—bulk materials are everywhere in the industry. With our RAPID series metal detection systems for free-fall applications, you achieve optimal results in quality assurance, incoming goods inspection, and machinery protection. Even under the highest hygiene standards.

Who Benefits from RAPID Free-Fall Metal Detectors?

Free-fall metal detectors inspect free-flowing bulk materials in vertical conveyors for metal contaminants. They reliably detect and separate both magnetic and non-magnetic metals, even when embedded in the product. They are especially crucial in industries with stringent purity standards, such as food and feed production.

Common applications include the food and feed industry, chemical and pharmaceutical production, and plastics processing. They are used wherever bulk materials need to be inspected for metal contaminants.

Metal detectors excel at detecting tiny metal particles, making them the most reliable devices in this field. Compared to X-ray inspection systems, they are more cost-effective to purchase and operate, and they don't require complex radiation protection measures. Integration into existing production lines is simpler and more adaptable.

Custom Kit Tailored to Your Needs

Unmatched Sensitivity to All Metals

Compliant and Secure: Easier Than Ever

Interested?

We see what you don't...

- Iron

- Steel

- Stainless Steel

- Non-Ferrous Metals

Common foreign bodies made of iron include machine parts, screws, nails, wires, or abrasion from conveyor belts and production equipment.

Food products can contain production residues like shavings, screws, or broken tools from mechanical processing.

Stainless steel often enters production through worn or damaged machine parts, pipelines, or cutting tools.

Aluminum, copper, or brass often come from packaging materials, cable scraps, piping, or worn machine parts.

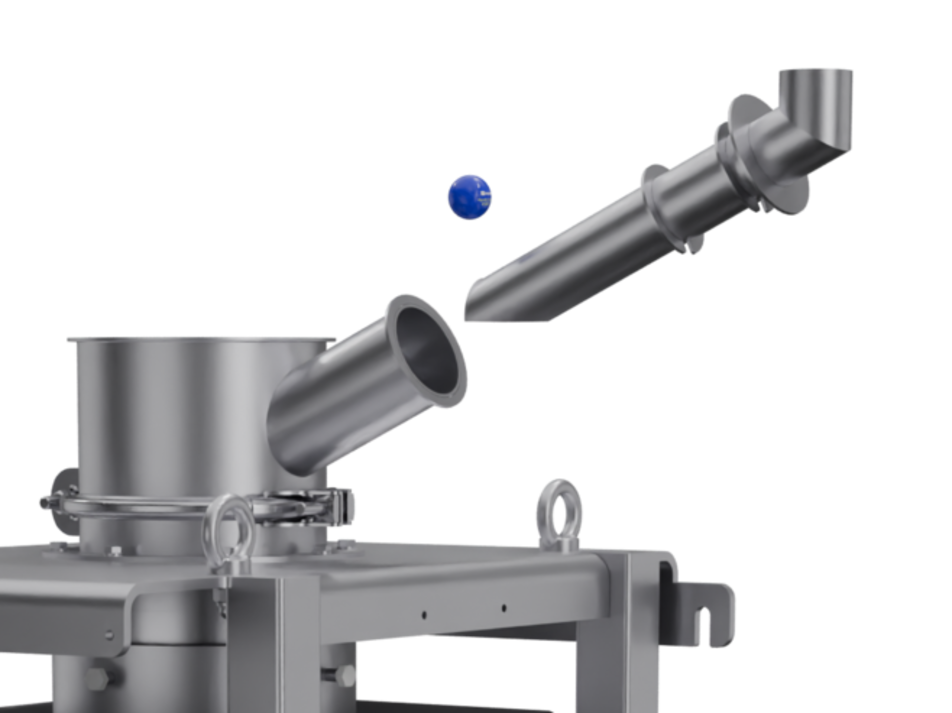

RAPID Metal Detectors in Detail

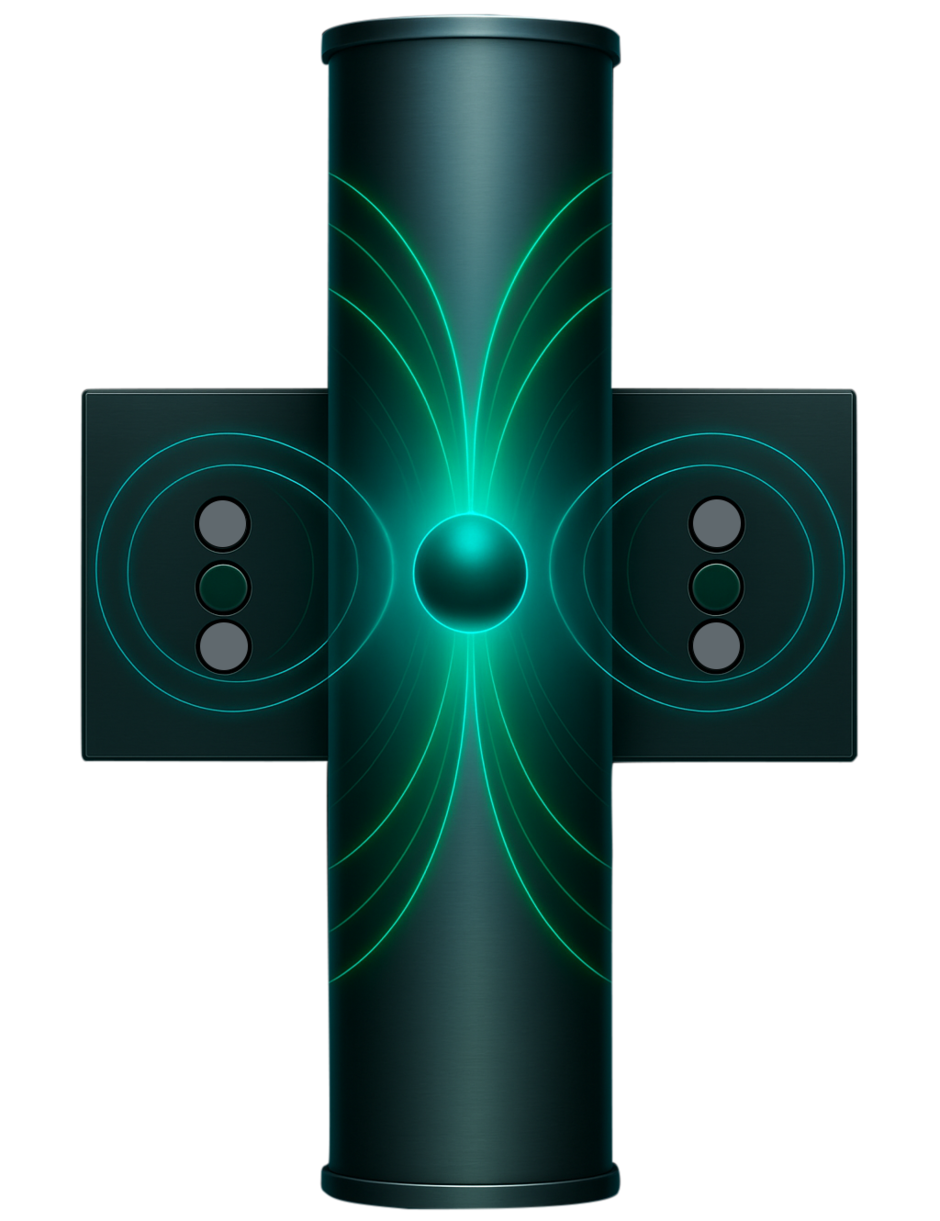

P-SCAN Metal Detector

Experience ultra-precise detection of magnetic and non-magnetic metals with single or dual-frequency technology.

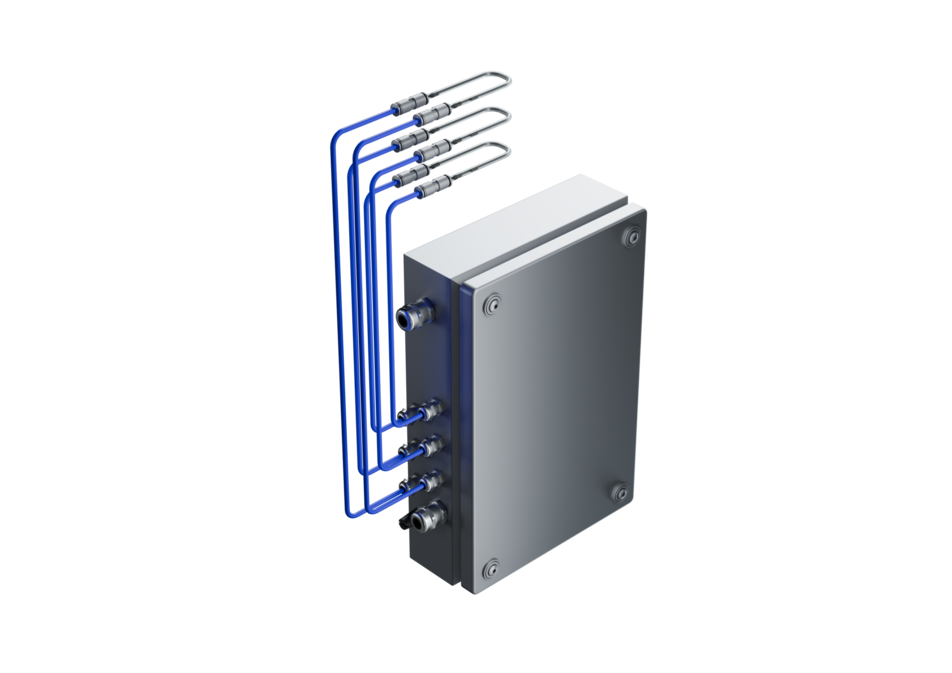

Control Unit

Intuitive touch-display operation with continuous self-monitoring of all critical system functions

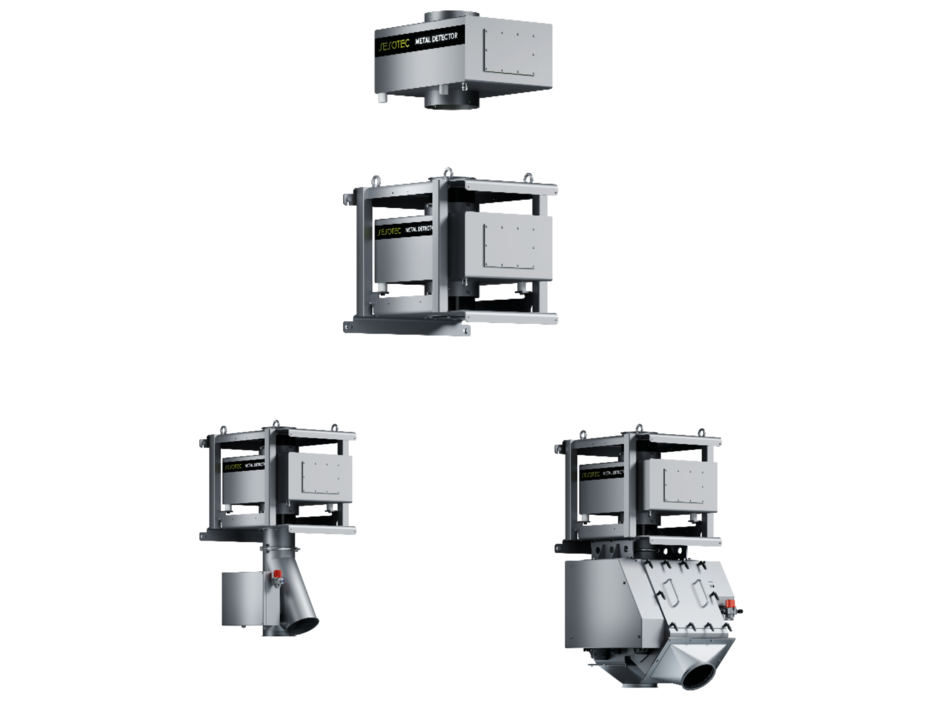

Various Reject Mechanisms

Versatile systems for diverse bulk materials and optimal metal separation

Tailored Designs for Every Need

Hygienic design for the food industry and ATEX options for explosive environments

P-SCAN Metal Detector

Experience ultra-precise detection of magnetic and non-magnetic metals with single or dual-frequency technology.

Control Unit

Intuitive touch-display operation with continuous self-monitoring of all critical system functions

Various Reject Mechanisms

Versatile systems for diverse bulk materials and optimal metal separation

Tailored Designs for Every Need

Hygienic design for the food industry and ATEX options for explosive environments

We deliver the perfect solution for every application—standard or customized

Durability through

Quality "Made in Germany"

10 years of parts availability,

rapid service response times

Metal Detection Systems for Your Industry

Sesotec's free-fall metal detectors ensure maximum product purity across diverse industries. They meet the highest hygiene standards, protect machinery from metal particle damage, and help prevent production downtime and recalls. Select Your Industry:

Food Industry

Metal detectors effectively eliminate contaminants from bulk goods like flour, sugar, nuts, spices, or dried fruits. They ensure compliance with hygiene and quality standards at various production stages.

Plastics Industry

Free-fall metal detectors safeguard production equipment like extruders and mills from damage caused by metal particles. They detect and separate metals from granules, regrind, flakes, and fibers.

Free-Fall Metal Detectors for the Food Industry

Your Priorities, Our Solutions

- Compliance

- Safety

- Control

- Hygiene

- Efficiency

- Service

Compliance and Precision

Achieve maximum detection sensitivity even with strong product effects through single or dual-frequency technology, automatic product compensation, digital signal processing and various test functions.

Safety for People & Products

Ensure the safe removal of metals with features like compressed air monitoring and separating unit oversight, delivering contamination-free products to your customers.

Easy-to-Use Interface

Configure our systems effortlessly for various applications using a 5" color touch display with intuitive menu navigation. Operating errors are virtually eliminated.

.png)

Sophisticated Hygiene Design

Durable and hygienic enclosures ensure effortless cleaning and maintenance.

Efficiency Across All Areas

Secure removal of metallic contaminants ensures contamination-free products. Intelligent sensitivity adjustment and high interference resistance prevent false rejects and boost profitability. Additional safety is provided by optional function test modules.

Reliable, Fast Service

With warranty services, a blend of on-site and remote support, and targeted training, you receive optimal assistance for seamless operations.

0

Grain Size0

Throughput0

detection accuracy

Innovative Technology

Reliable detection of magnetic and non-magnetic metal contaminants with single or dual-frequency technology.

Inline Test Device in XS

Comfortable and compact for enhanced compliance

One Product Family – Diverse Solutions

Our Free-Fall Metal Detectors for the Food Industry

Brochure

Download

Discover a comprehensive overview of all technical details for our product family designed for free-fall applications in our brochure.

Free-Fall Metal Detectors for the Plastics Industry

Your Priorities - Our Solutions

- Material Efficiency

- Process Reliability

- Quality Assurance

Material Efficiency

Recyclers and plastic manufacturers and processors face fluctuating material availability amid high demand. The higher the quality of the raw material, the more efficient the processing.

Process Reliability

Contaminated raw materials often lead to equipment failures and material waste. Advanced detection technologies ensure pristine raw materials, paving the way for smoother production.

Quality Assurance

Consistent product quality is the foundation of economic success. Streamlined production processes with minimal waste enhance your competitive edge.

0

detection accuracy0

Throughput0

Grain Size

Innovative Technology

Reliable detection and separation of magnetic and non-magnetic metal contaminants from granular, fibrous, and powdered bulk materials.

Customizable for Every Need

Choose from over 30 spool variants to meet diverse needs. The modular design lets you customize the drop height and outlet position for optimal contamination control.

One Product Family – Diverse Solutions

Our Free-Fall Metal Detectors for the Plastics Industry

Brochure

Download

Discover a comprehensive overview of all technical details for our product line designed for free-fall applications in our brochure.

ADD-ONS & SERVICES

Smart Add-ons for Enhanced Performance

Insight.WEB, the visualization software for metal detectors, -separators and product inspection systems, brings transparency to your production processes, offering a clear overview for enhanced efficiency and increased profitability. Our smart machine monitoring reduces downtime and maximizes your OEE (Overall Equipment Effectiveness).

Centralized Control of

All Sesotec and Third-Party Devices

Clear Visualization & Control

of Your Processes

Maximize Profitability with

Data-Driven Process Optimization