Cutting-Edge Tech for the Most Demanding Needs

Metal contamination in production is a challenge impacting many industries, from food manufacturing to plastics and recycling.

Sesotec metal detectors use inductive technology to reliably detect all types of metal foreign bodies. When combined with a separating unit, contaminated products can be automatically removed.

We see metals you don't...

- Metallic foreign bodies

- Smallest Metal Pieces

Our systems reliably detect all types of metal – from ferrous and non-ferrous to stainless steel.

Sesotec metal detectors detect even the tiniest metal particles, ensuring maximum purity and product quality.

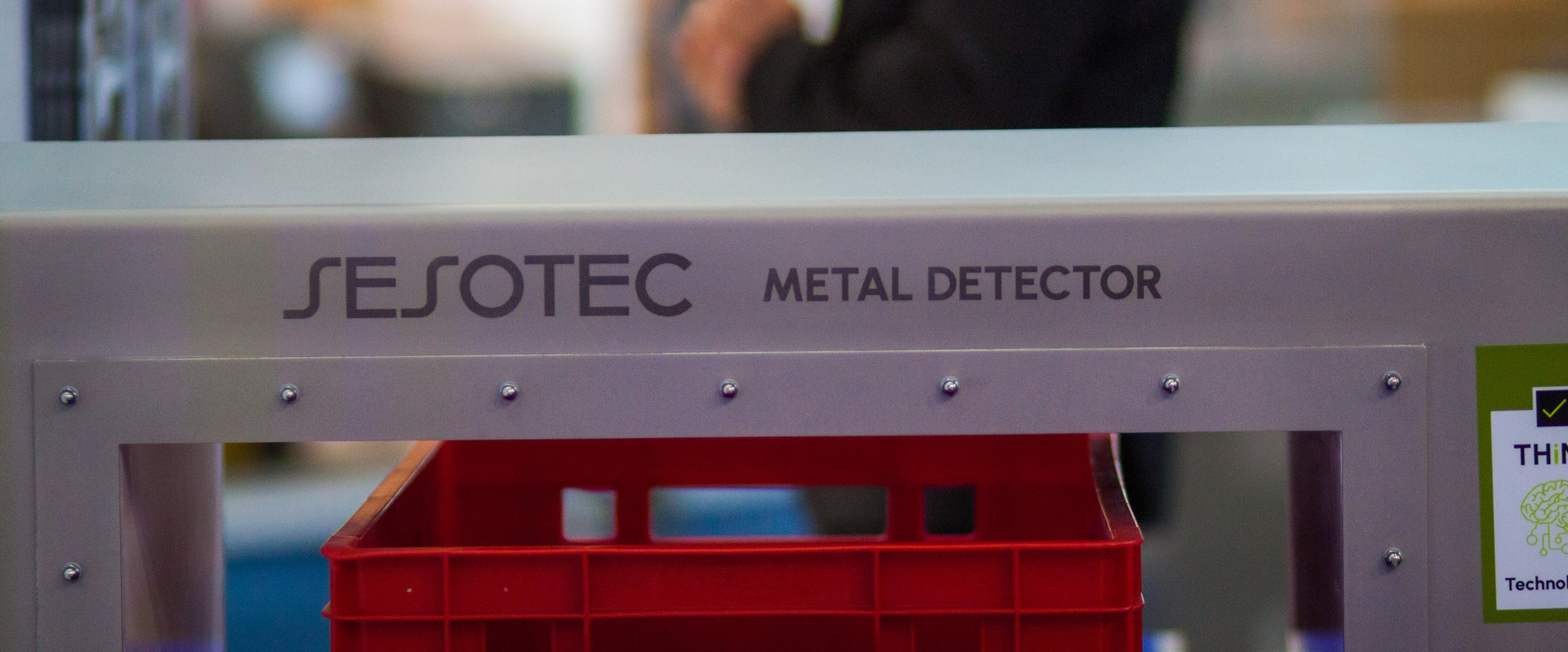

Metal Detectors for the Most Demanding Standards

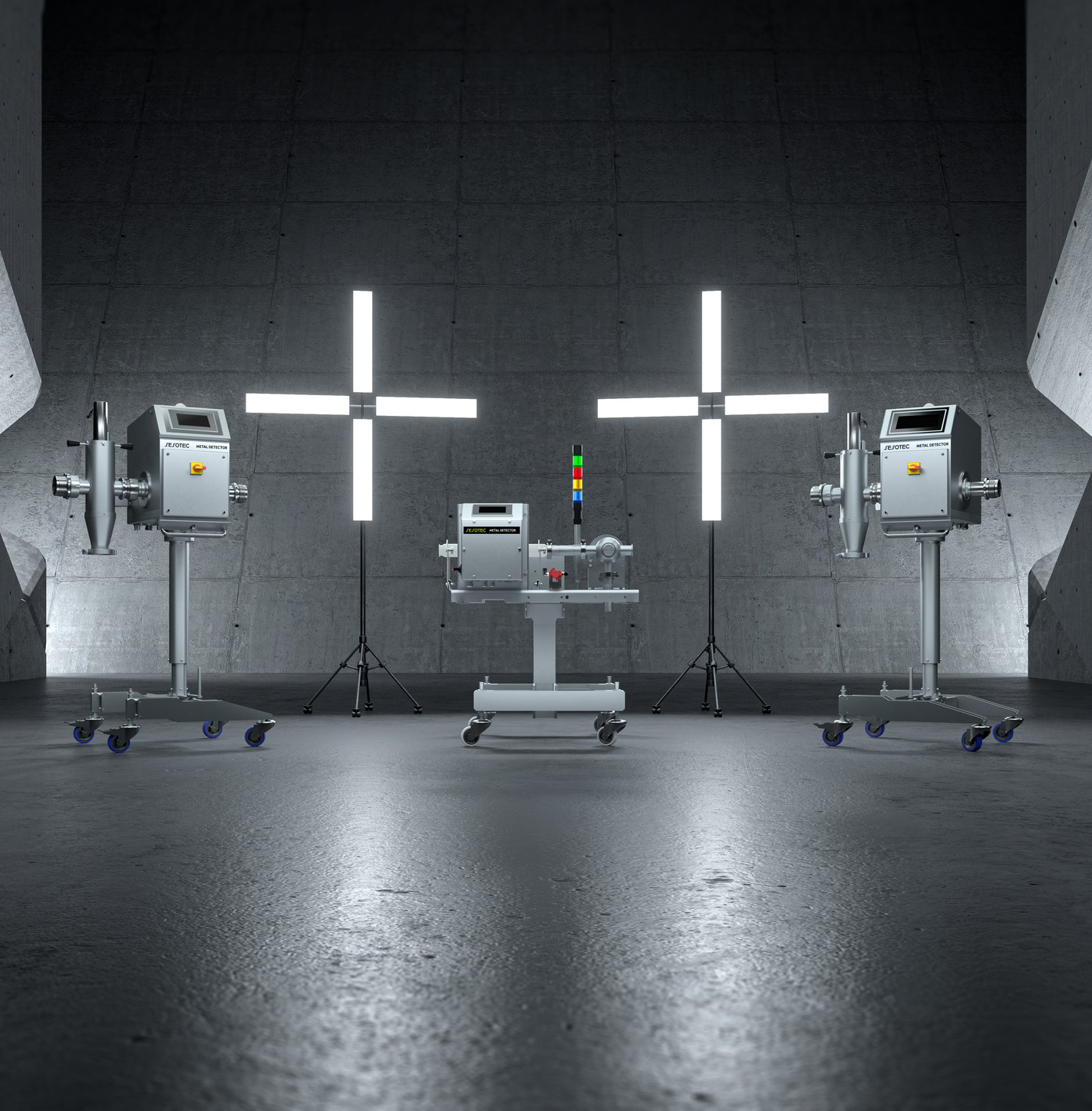

Discover Our Product Families

Why Choose Metal Detection & Separation with Sesotec

Sesotec metal detection systems identify not just iron or magnetic materials, but all types of metal.

Sesotec systems for metal detection and separation identify even the smallest metallic foreign bodies, ensuring that only top-quality products reach your customers – together, we protect your brand.

With THiNK, the AI-powered software for Sesotec metal detectors, the product effect in food can be significantly better masked than with conventional metal detectors.

Metallic foreign bodies in production can damage machinery and, in the worst case, lead to a shutdown. Detection systems from Sesotec reliably help prevent these scenarios.

How Metal Detection and Separation Works with Sesotec

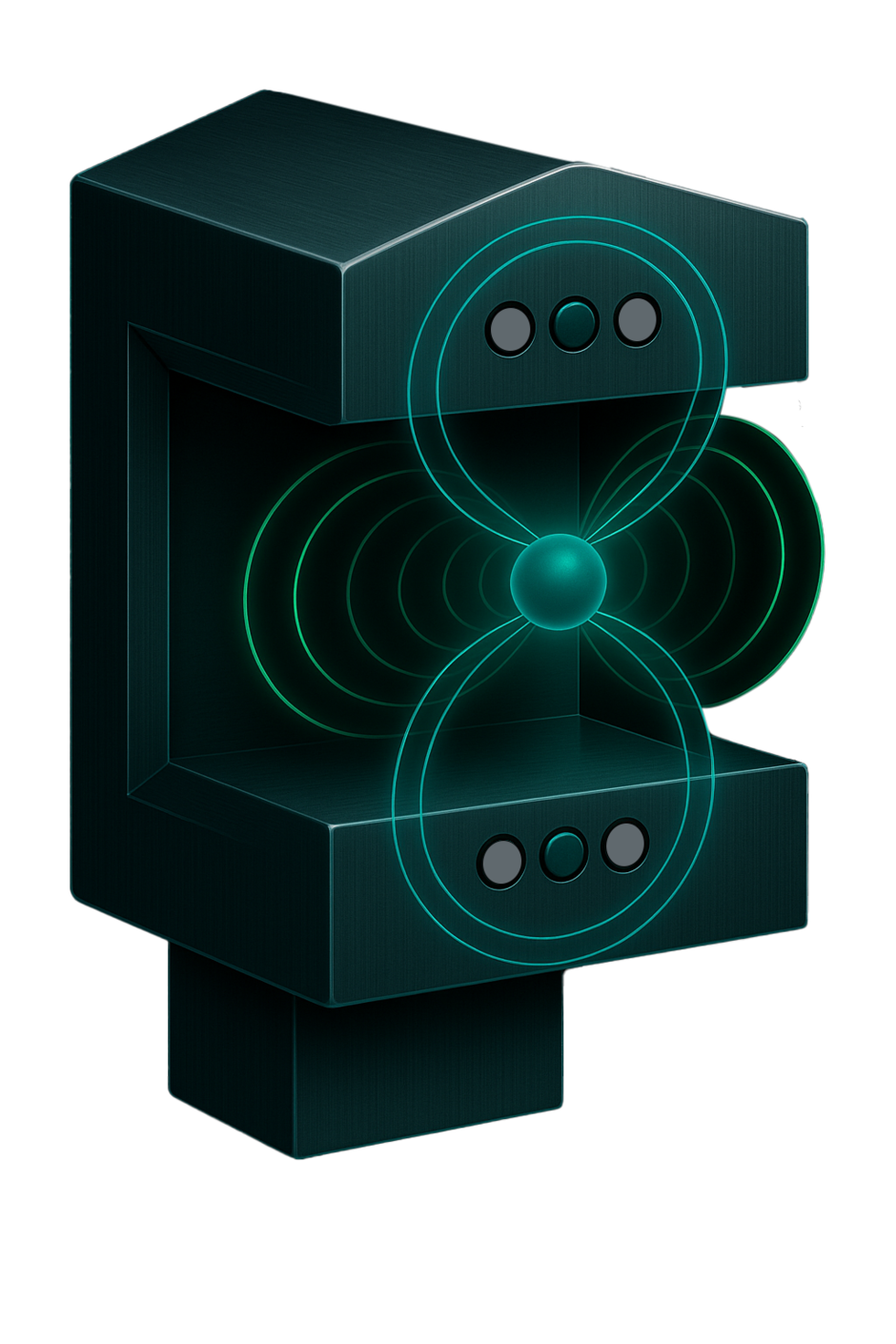

Detection through Induction

Sesotec metal detection systems utilize the transmitter-receiver method. This operates on the principle of electrical induction: when a metal object disrupts the electromagnetic field, it is logged as an error message.

Digital Signal Processing

The software analyzes the measured signals using algorithms, reliably distinguishing metallic foreign bodies from disruptive influences—whether from the environment or the product itself.

Low-Loss Separation

Choose from swing arms, air nozzles, pushers, drop gates, swivel chutes, and retracting belts to automatically, safely, and efficiently remove contaminated products.

0

Experience0

Types of Funding0

Sub-industriesInductive Metal Detection – Simplified

Metal Detection and Separation for Your Industry

Sesotec's metal detectors and separators are primarily used in the food, plastics, and recycling industries. These systems ensure maximum product safety, protect machinery, and enable precise material separation – enhancing quality and efficiency across all sectors.

Food

Metal contaminants must be consistently detected and removed during food production. This is essential not only to comply with standards like IFS, BRC, and FSMA, but also to protect consumers from health risks and prevent costly recalls.

Plastics/Recycling

Sesotec systems reliably detect and remove metallic contaminants across diverse areas of plastics processing and recycling. They protect machinery from damage, enhance product quality, and ensure efficient production.

ADD-ONS & SERVICES

Smart Add-ons for Enhanced Performance

Insight.WEB, the visualization software for metal detectors, -separators and product inspection systems, brings transparency to your production processes, offering a clear overview for enhanced efficiency and increased profitability. Our smart machine monitoring reduces downtime and maximizes your OEE (Overall Equipment Effectiveness).

Centralized Control of

All Sesotec and Third-Party Devices

Clear Visualization & Control

of Your Processes

Maximize Profitability with

Data-Driven Process Optimization

Compliance – Anytime, Anywhere

The Compliance Package for Food ensures seamless and efficient documentation of your production – featuring Audit Check, Sensitivity Prediction, Compliance Mode, ICM, and IVP.

AI-Powered Metal Detection

Experience the next generation of product safety: Our adaptive AI software THiNK virtually eliminates the product effect, enabling the effective detection of even the smallest metal fragments.