Pure Plastics. Perfectly Sorted.

Recycling saves energy, and used plastics are often more cost-effective than new materials. Plus, every ton of recycled plastic used instead of new material prevents between 1.45 and 3.22 tons of climate-impacting greenhouse gases. However, profitable recycling of plastic waste is only possible if the material is color and type sorted to meet high-quality standards. Our sorting systems handle the task: they sort PET, HDPE, PE, PVC, and many more—precisely, reliably, and efficiently.

Streamline Your Choices.

Colors

Harness the power of camera technology for precise color sorting.

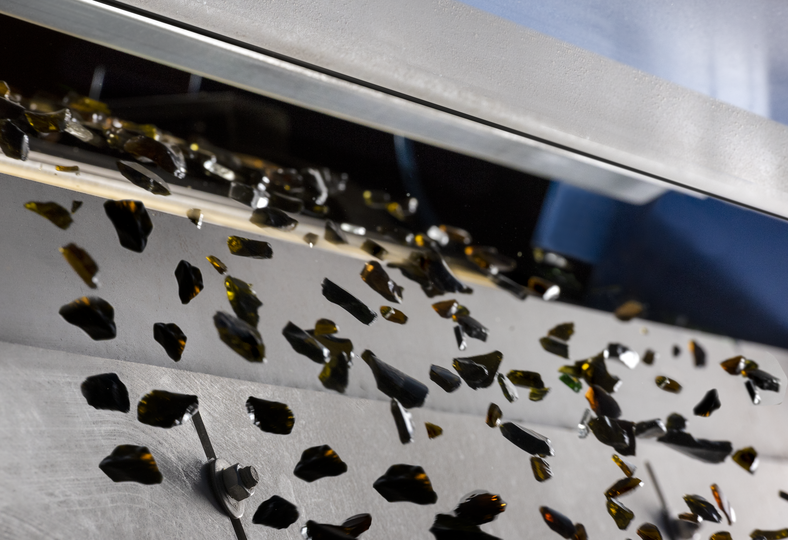

Metals

Magnetic and inductive sorting systems detect and separate metal parts from plastic waste.

Plastics like PET, HDPE, PVC, and more

Our sorting systems identify and separate plastics like PET, HDPE, and PVC by analyzing their unique chemical and physical properties.

Contaminants (e.g., wood, paper, bioplastics)

Our optical sorting systems efficiently eliminate contaminants, enhancing the quality of recycled plastics.

Colors

Harness the power of camera technology for precise color sorting.

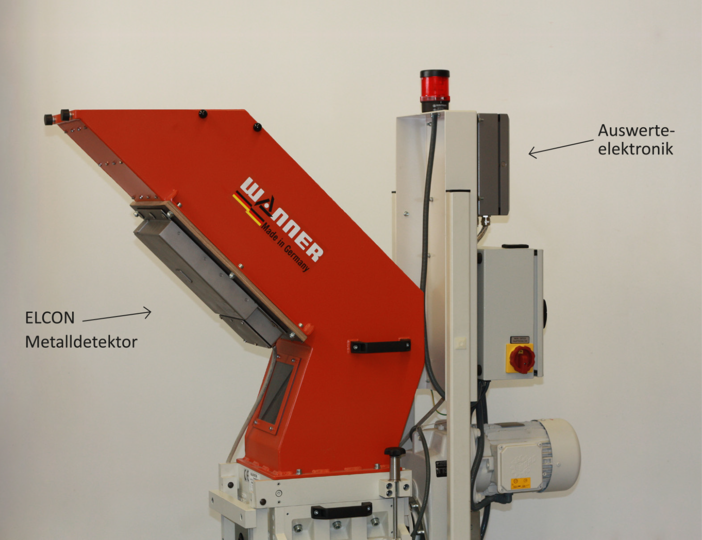

Metals

Magnetic and inductive sorting systems detect and separate metal parts from plastic waste.

Plastics like PET, HDPE, PVC, and more

Our sorting systems identify and separate plastics like PET, HDPE, and PVC by analyzing their unique chemical and physical properties.

Contaminants (e.g., wood, paper, bioplastics)

Our optical sorting systems efficiently eliminate contaminants, enhancing the quality of recycled plastics.

Interested in recycling one of these materials?

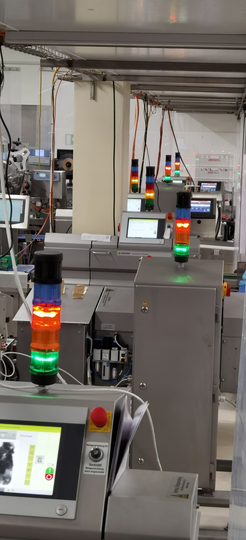

- SORTING SYSTEMS

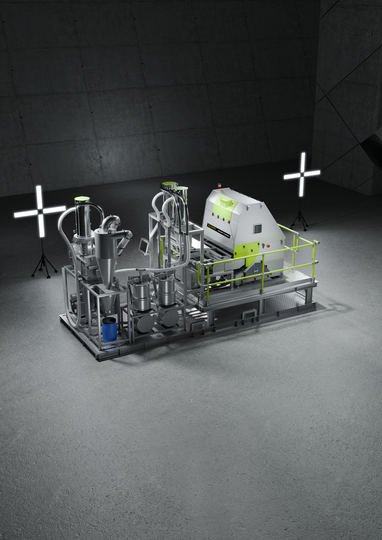

- MATERIAL MANAGEMENT SYSTEMS

- MAGNETIC SYSTEMS

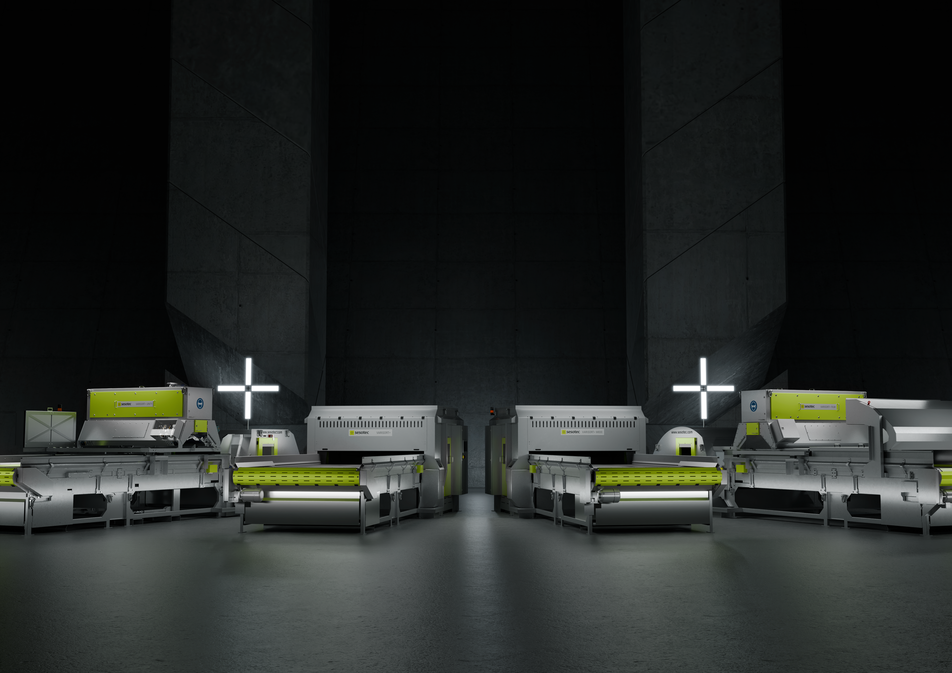

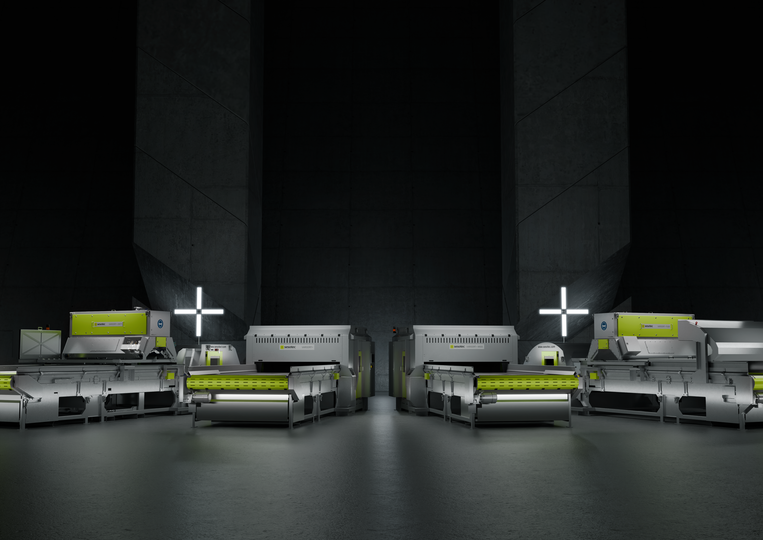

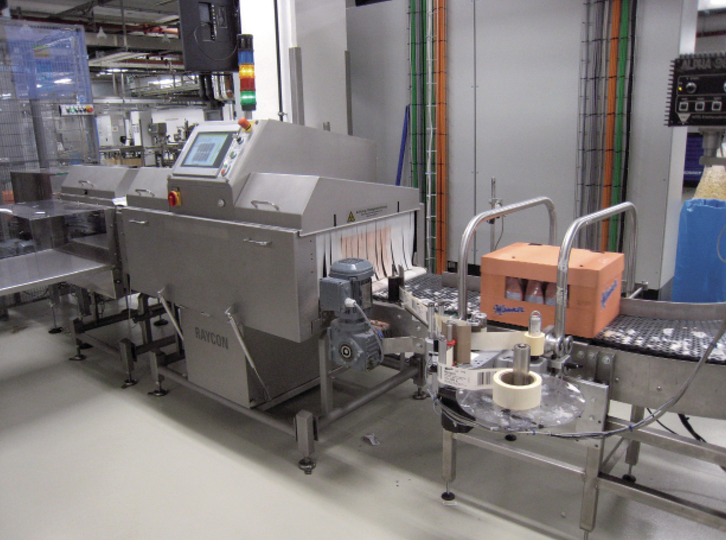

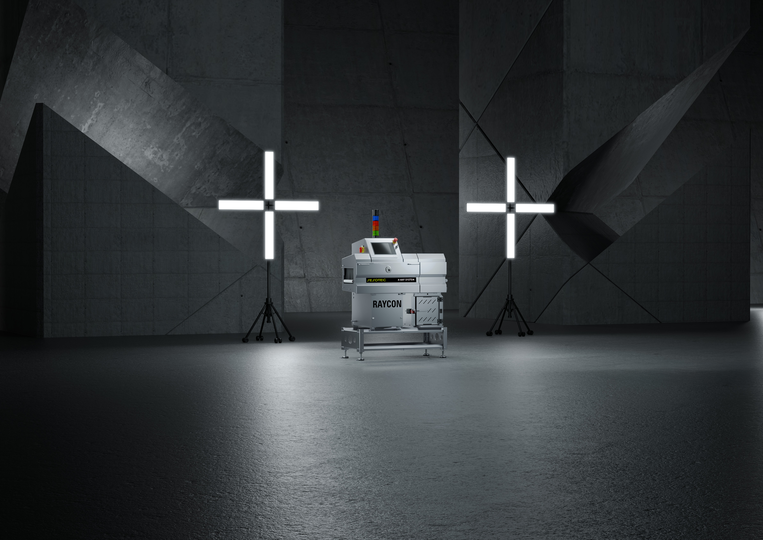

Sorting Systems

Our sorting machines are modular by design: Depending on your needs, we can integrate various sensors, detectors, and separators into a single device. Unwanted materials are precisely removed from the material flow in milliseconds using separation systems like air jets and flaps.

READ MORE

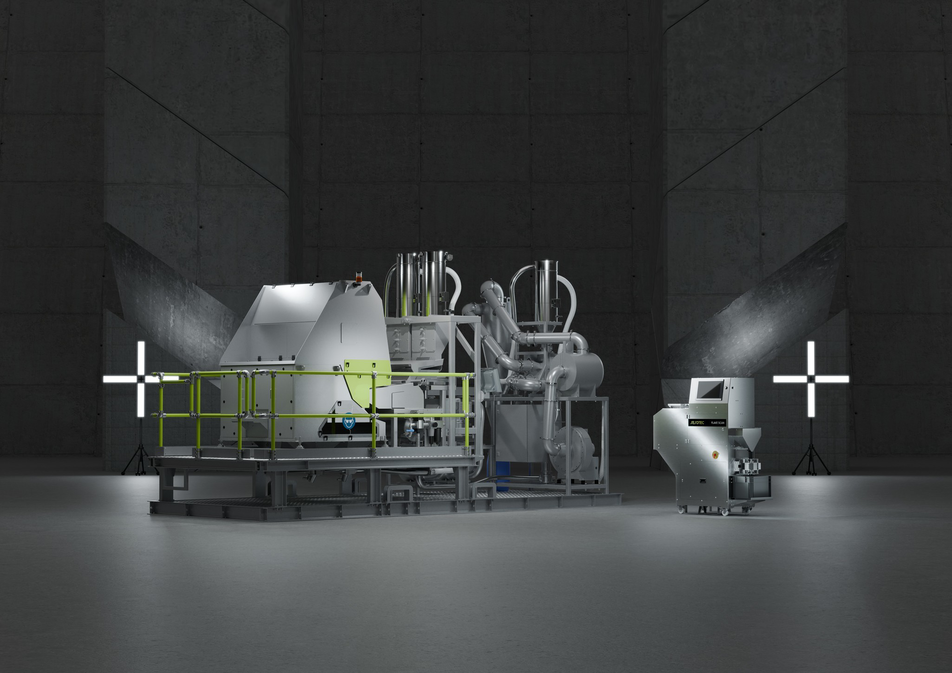

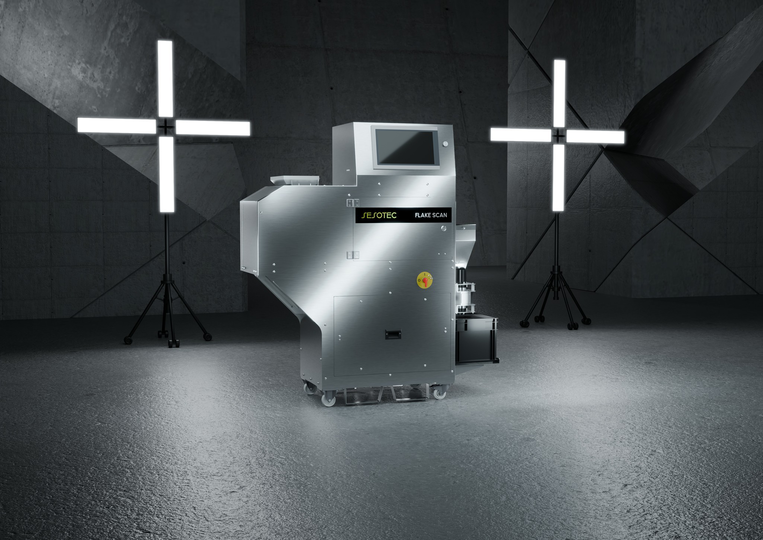

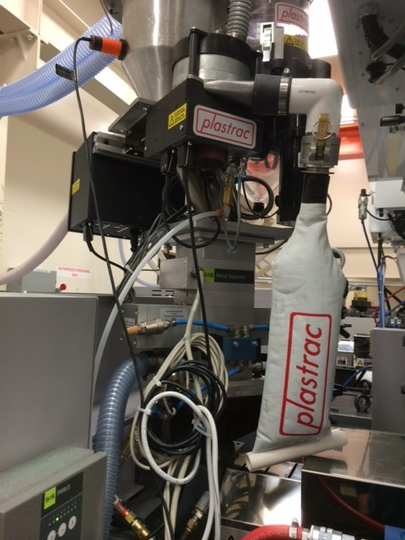

Material Management Systems

The PRE-SORT and FLAKE SCAN sorting systems empower plastic processors with customizable sorting processes and rapid sample analysis by plastic type, color, and metal foreign bodies. Achieve high-quality, pure materials and cost-effective production.

READ MORE

Magnetic Systems

Our magnetic systems deliver exceptional magnetic performance and efficient design to remove even the finest ferrous metal contaminants. Strategically arranged magnetic rods achieve maximum separation efficiency. They integrate easily and quickly into piping systems, hoppers, or directly at material inlets—even in existing production lines.

READ MORE

Where do plastic recyclers implement Sesotec sorting systems?

Businesses worldwide rely on Sesotec sorting systems to efficiently separate materials and reclaim valuable resources.

Our systems ensure the effective sorting of all types of plastics.

Plastic Bottles

Sesotec sorting systems efficiently identify and separate different bottle types, enabling precise recovery of pure materials for recycling.

Plastic Cups

Sesotec sorting systems separate cups made from various plastics like PP or PS.

Plastic Regrind

Sesotec sorting systems identify and separate plastic regrind, such as that generated from production waste.

Plastic Flakes

Plastic flakes are separated by precise sorting technologies according to material type and color, enabling their reuse in high-quality products.

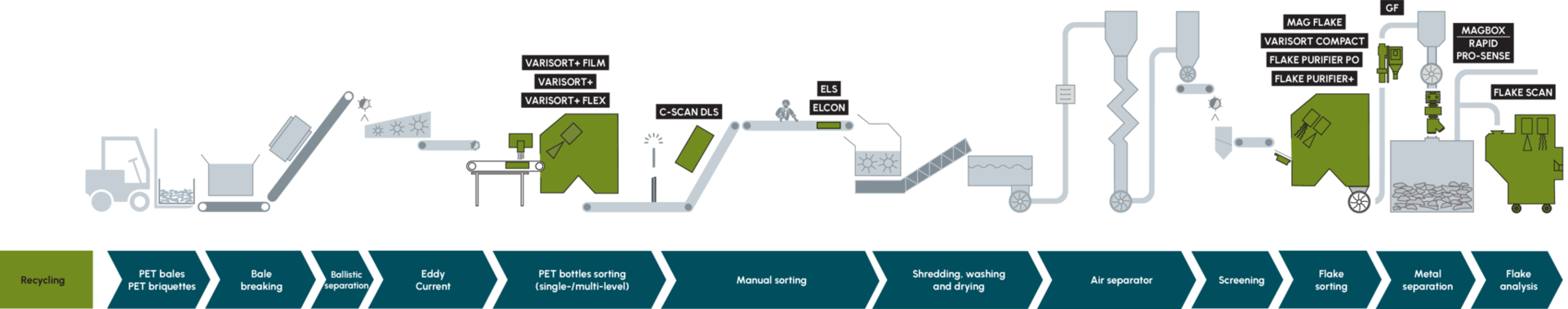

Across the entire production line.

From intake inspection to sorting and analysis, our systems reliably separate and analyze. They ensure high material quality and efficient recycling throughout the entire process.

Discover the Perfect Sesotec Solution with Ease:

Ready to discover more?

ADD-ONS & SERVICES

Smart Enhancements for Unmatched Performance

Unlock actionable insights from process data to boost the efficiency of your sorting and recycling operations and minimize downtime. VISUDESK, the visualization software for sorting machines and systems, brings transparency to your sorting processes with process data, enabling direct control for enhanced efficiency and profitability.

Enhance Clarity in

Your Sorting Processes

Unleash Total Control

Over Your Sorting Systems

Boost Profitability with

Data-Driven Optimization

We understand the challenges of plastic recycling.

Recover Valuable Secondary Raw Materials

Sorting systems enable the efficient separation and recovery of diverse raw materials. This conserves natural resources and reduces the demand for new materials.

Ensure the Safe Removal of Contaminants

Ensuring the safe removal of contaminants in recycling is crucial for maintaining material quality, preventing process disruptions, and protecting machinery.

Customer Demands and Quality.

Sesotec sorting systems ensure material purity that meets your customers' quality standards. Strengthen your market position and promote sustainable economic cycles.

Legal Requirements

Meet regulatory requirements effortlessly with Sesotec sorting systems, ensuring compliance with waste separation and recycling quotas.

Sesotec's sorting systems are the ideal choice for sorting and cleaning diverse material groups.

Explore Our Case Studies

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.jpg)

.jpg)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.JPG)

.jpeg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.jpg)