MEAT & SAUSAGE PRODUCTS

When the stakes are high, be secure.

Foreign body detection is crucial in meat and sausage production. Contaminants not only compromise product quality but also pose a threat to consumer health. They also risk damaging production facilities and can lead to costly and reputation-damaging recalls.

The Most Common Foreign Bodies in Meat and Sausage Production

Broken syringes from fattening

Broken syringe needles in livestock farming pose a serious safety risk and must be detected early to ensure safe products.

Bones

Unintended bone fragments left in the product compromise the final product's quality and pose a risk of injury to consumers.

Metal Wear from Conveyor Systems

Metal abrasion from wear in conveyor systems can silently infiltrate food products, becoming a common source of contamination in production.

Protective Gear Components

Fragments of protective gear, like pieces of chainmail gloves or safety goggles, can accidentally enter the production process and must be consistently detected and removed.

Sausage Clips

Sausage clips can easily enter the product during machine processing, but our detection solutions identify them effortlessly.

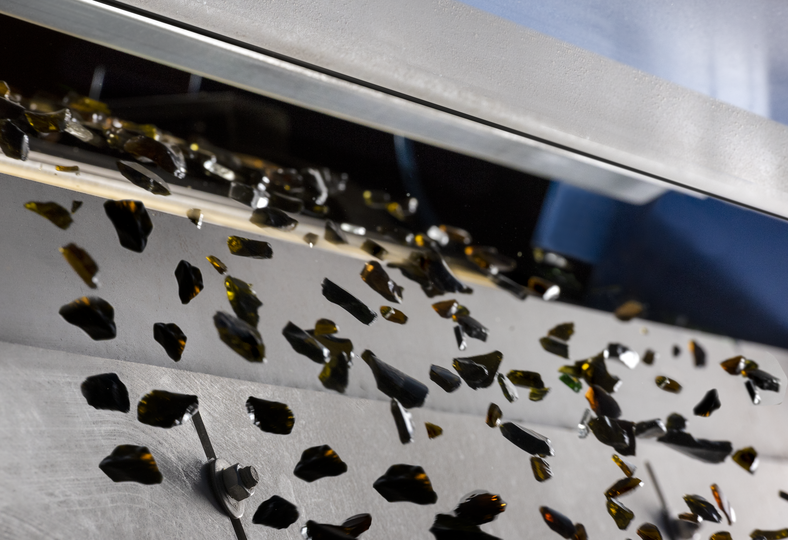

Shattered Glass

Glass shards can enter meat and sausage products as foreign bodies due to damaged glass containers or machine errors. Removing them is crucial to prevent consumer injuries and costly recalls.

Broken syringes from fattening

Broken syringe needles in livestock farming pose a serious safety risk and must be detected early to ensure safe products.

Bones

Unintended bone fragments left in the product compromise the final product's quality and pose a risk of injury to consumers.

Metal Wear from Conveyor Systems

Metal abrasion from wear in conveyor systems can silently infiltrate food products, becoming a common source of contamination in production.

Protective Gear Components

Fragments of protective gear, like pieces of chainmail gloves or safety goggles, can accidentally enter the production process and must be consistently detected and removed.

Sausage Clips

Sausage clips can easily enter the product during machine processing, but our detection solutions identify them effortlessly.

Shattered Glass

Glass shards can enter meat and sausage products as foreign bodies due to damaged glass containers or machine errors. Removing them is crucial to prevent consumer injuries and costly recalls.

Facing foreign bodies in your meat and sausage products?

Meat and Sausage? Safety First!

- X-ray Inspection

- Metal Detection

- Magnetic Systems

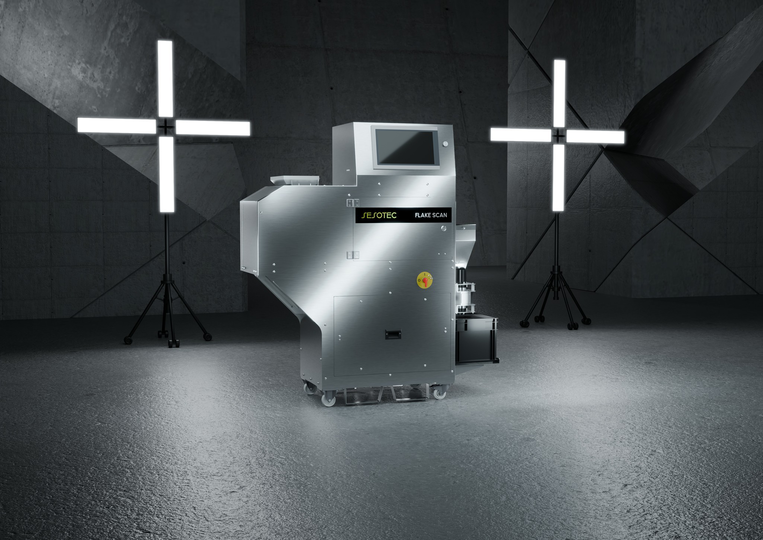

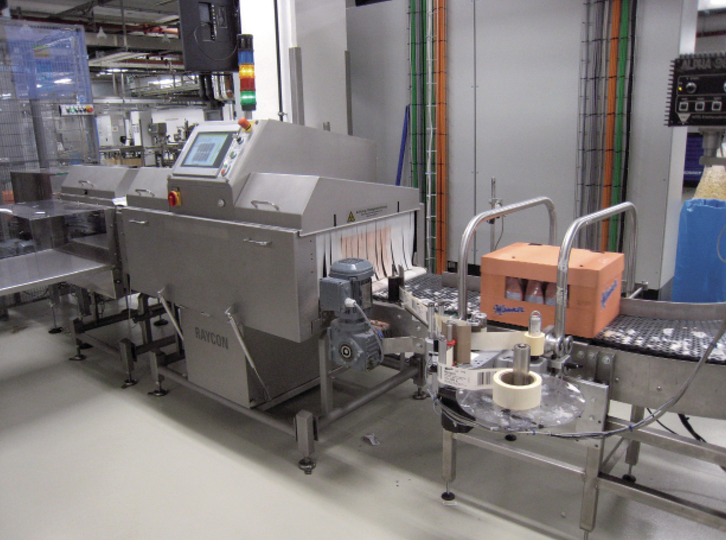

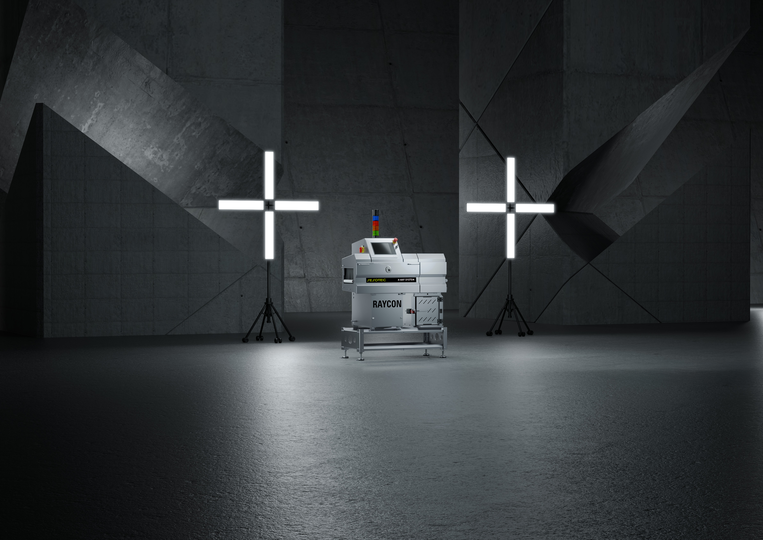

X-ray Inspection

Our X-ray inspection systems ensure the highly precise detection of foreign bodies such as metal, glass, or bone in meat and sausage products.

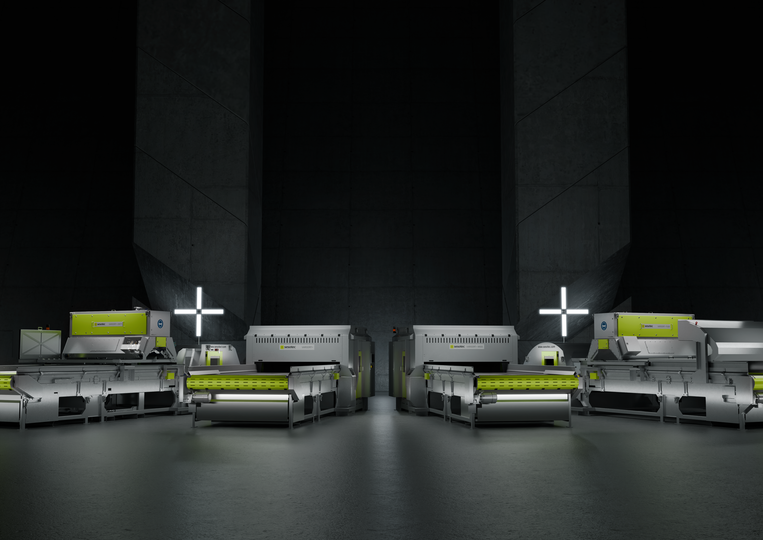

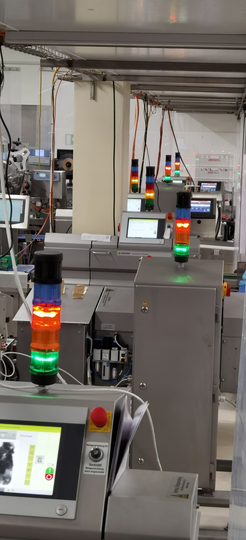

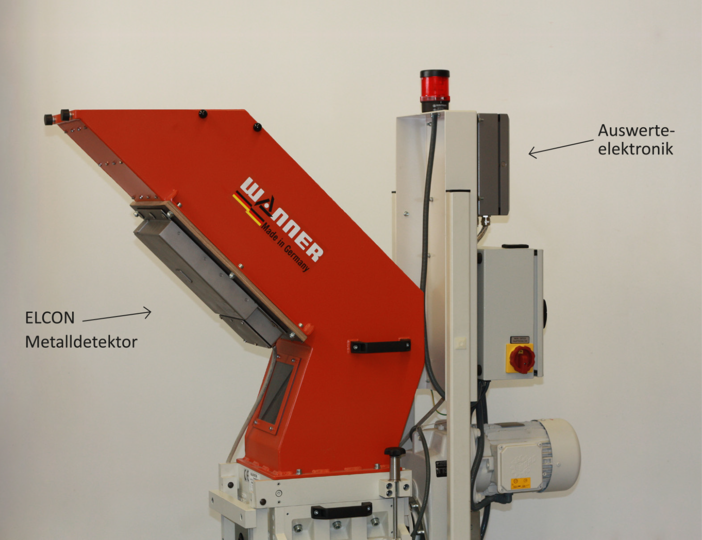

Metal Detection

Sesotec metal detection systems ensure the reliable identification of metallic contaminants in meat products.

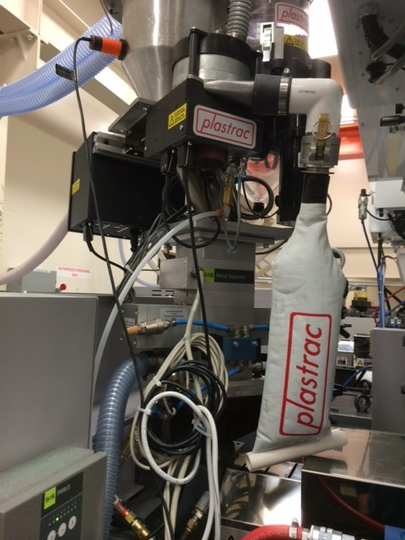

Magnetic Systems

Sesotec's magnetic systems efficiently eliminate metallic contaminants like iron filings from meat products before further processing.

Where Do Meat Processors Use Our Equipment?

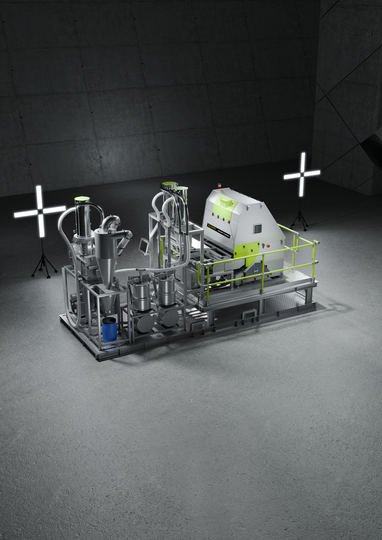

Whether right after cutting, during meat processing, or for final inspection of packaged products – we offer tailored solutions for foreign body detection at every stage of meat and sausage production.

Our systems detect and remove foreign bodies in the following products, among others:

Pre-packaged Raw Meat

Contamination can occur during the final packaging process, making a last, precise foreign object inspection necessary.

Sausage Meat Before the Filler

Before filling, the sausage meat must be thoroughly checked for foreign bodies to ensure a pure final product and prevent potential production damage.

Sliced products after packaging

In the final quality check of packaged cold cuts, even the smallest foreign bodies can be detected before the product reaches the customer.

Ground Meat

As ground meat is finely minced during processing, meticulous foreign body detection is crucial to identify even the smallest metal particles or other contaminants.

Convenience Food

Convenience products often contain multiple ingredients, making comprehensive foreign body control essential to ensure consistent quality and safety for consumers.

Across the Entire Production Line

From goods receipt to production to dispatch—our metal detection and X-ray inspection systems ensure top-tier product purity and safe food production at every stage.

Discover the Perfect Sesotec Solution with Ease

Interested?

ADD-ONS & SERVICES

Smart Add-ons for Enhanced Performance

Insight.WEB, the visualization software for metal detectors, -separators and product inspection systems, brings transparency to your production processes, offering a clear overview for enhanced efficiency and increased profitability. Our smart machine monitoring reduces downtime and maximizes your OEE (Overall Equipment Effectiveness).

Centralized Control of

All Sesotec and Third-Party Devices

Clear Visualization & Control

of Your Processes

Maximize Profitability with

Data-Driven Process Optimization

We understand the challenges of the meat and sausage industry

CERTIFICATIONS AND AUDITS

Effective foreign body detection is a critical quality factor in meat and sausage production, especially in the context of certifications and audits. Reliable foreign body detection plays a crucial role in maintaining hygiene standards and meeting quality requirements according to international standards like IFS or BRC.

LEGAL REQUIREMENTS

Laws like the EU Regulation 178/2002 and national food laws require meat and sausage producers to implement effective measures to prevent food contamination with foreign bodies. Failure to comply with these legal requirements can lead to consequences such as recalls, fines, or the revocation of operating licenses.

CUSTOMER REQUIREMENTS

Customers rightly demand the highest level of product safety and quality from meat and sausage producers. Consumers and trade partners increasingly seek guaranteed safety, and even the slightest contamination can permanently damage brand trust.

PROTECTION AGAINST RECALLS AND DAMAGES

Meat processing companies must minimize all risks of recalls, reputational damage, and legal consequences.

It feels great to have the latest and best technology in use.

View Case Study

FAQs for the Meat and Sausage Industry

Foreign bodies like metal parts can enter products during production. Metal detectors and X-ray inspection systems ensure product safety, meet legal requirements, and protect your brand from recalls and reputational damage.

Sesotec's inspection systems detect magnetic and non-magnetic metal parts (e.g., steel, stainless steel, aluminum) as well as glass, stone, ceramics, and high-density plastics that may be present in meat and sausage products.

Yes, our systems are specifically optimized for inspecting products with high conductivity, such as fresh, wet meat or frozen goods. Our technology minimizes false rejects and delivers reliable results.

Sesotec's inspection systems for the meat and sausage industry are designed to meet the highest hygiene standards (e.g., HACCP, IFS, BRC). Crafted from food-grade materials, they are engineered for easy cleaning in wet environments.

Yes, our solutions are flexible and can be integrated into both new and existing production lines. Our experts assist you in planning and implementation to ensure seamless integration.

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.jpg)

.jpg)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.JPG)

.jpeg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.jpg)