Plastic Without Compromise

Plastic production is a key sector in petrochemicals, where product purity is a critical quality standard. It's essential to eliminate metal parts and particles, as they can damage machinery and cause quality issues during further processing. As a plastic manufacturer, you should rely on automated foreign body detection to ensure you consistently deliver high-quality granulate.

Remove What Doesn't Belong

Conveyor Line Wear and Tear

Metal or plastic particles can form in pipelines due to friction, pressure, and movement, especially during extended operation or high material flow rates.

Machine Wear and Tear

Mechanical components like screw conveyors, pumps, or valves wear down due to constant contact with raw materials, potentially introducing small particles into the production line.

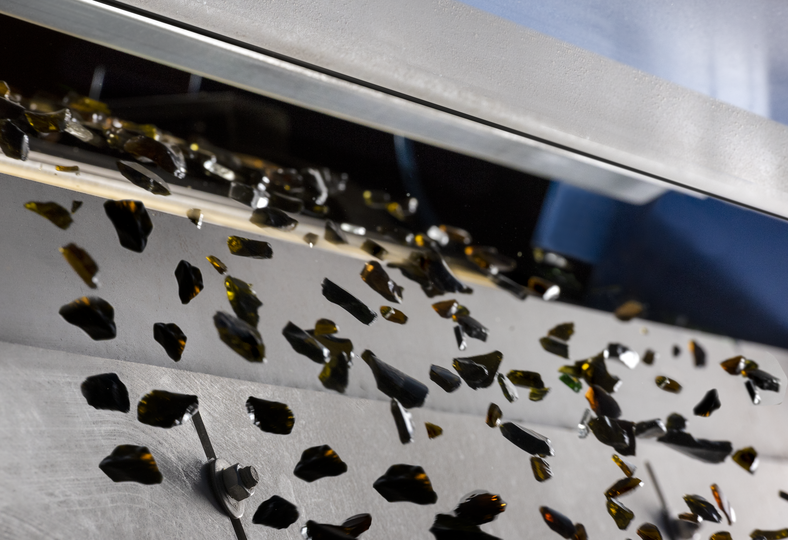

Broken blades during hot or cold cutting

Damaged or overused cutting tools can break during the cutting process, causing metal fragments to contaminate plastic granules or pellets.

Accidental Contamination Through Silo Openings

Open access points on silos can lead to contamination, such as lost items from personnel like tools or other foreign bodies.

Conveyor Line Wear and Tear

Metal or plastic particles can form in pipelines due to friction, pressure, and movement, especially during extended operation or high material flow rates.

Machine Wear and Tear

Mechanical components like screw conveyors, pumps, or valves wear down due to constant contact with raw materials, potentially introducing small particles into the production line.

Broken blades during hot or cold cutting

Damaged or overused cutting tools can break during the cutting process, causing metal fragments to contaminate plastic granules or pellets.

Accidental Contamination Through Silo Openings

Open access points on silos can lead to contamination, such as lost items from personnel like tools or other foreign bodies.

Facing challenges with these or other foreign bodies?

- Metal Detection and Separation

- Magnetic Systems

- Material Management

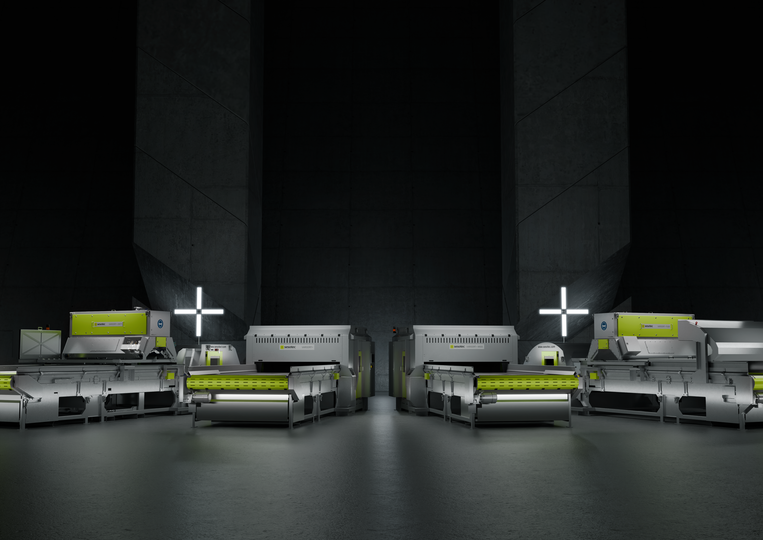

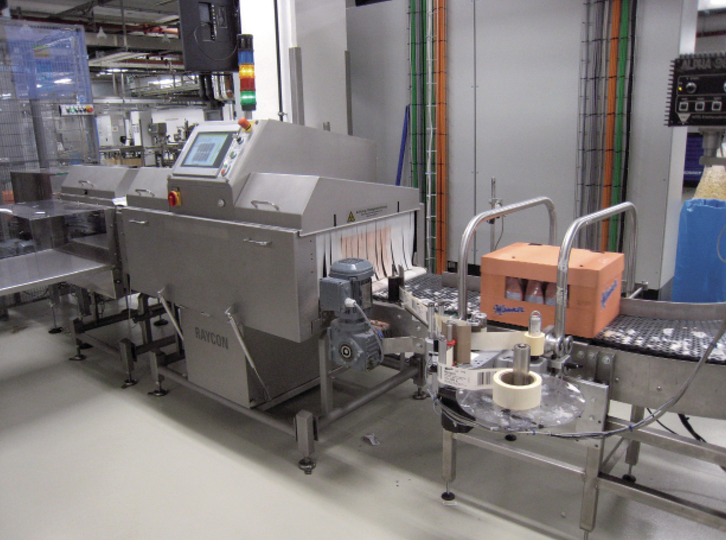

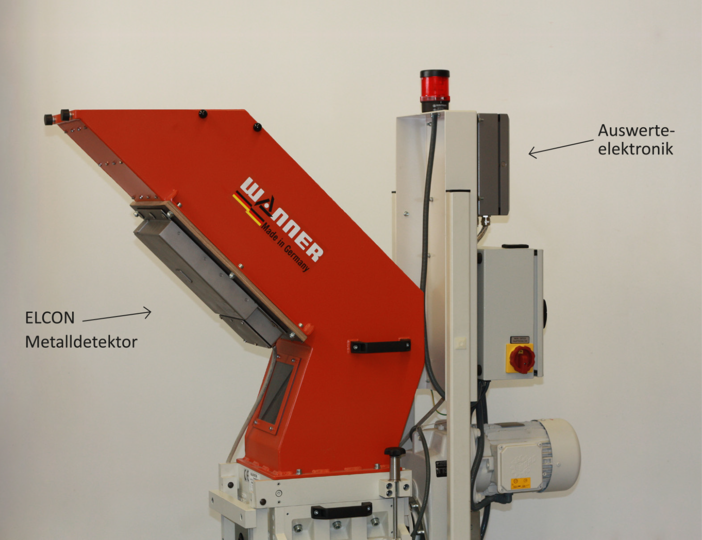

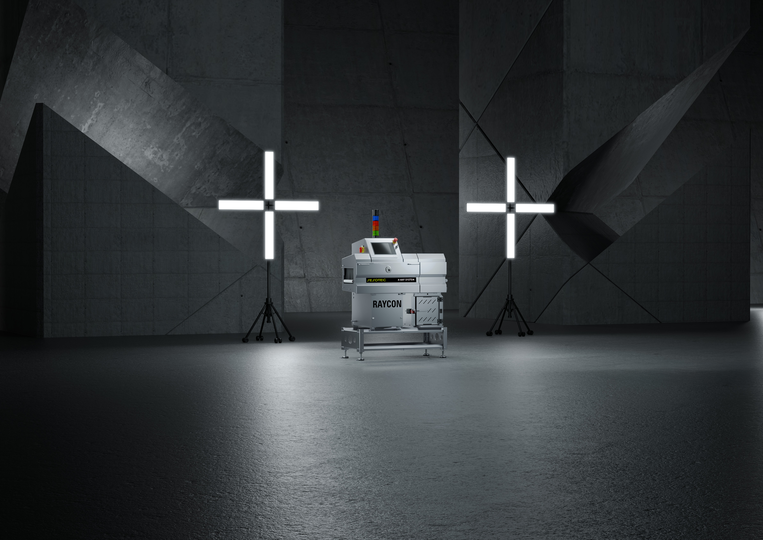

Metal Detection and Separation

With inductive technology, Sesotec metal detection systems identify all metallic foreign bodies in plastic production.

Magnetic Systems

Sesotec magnetic systems deliver exceptional magnetic performance and efficient design to eliminate even the finest ferrous metal contaminants.

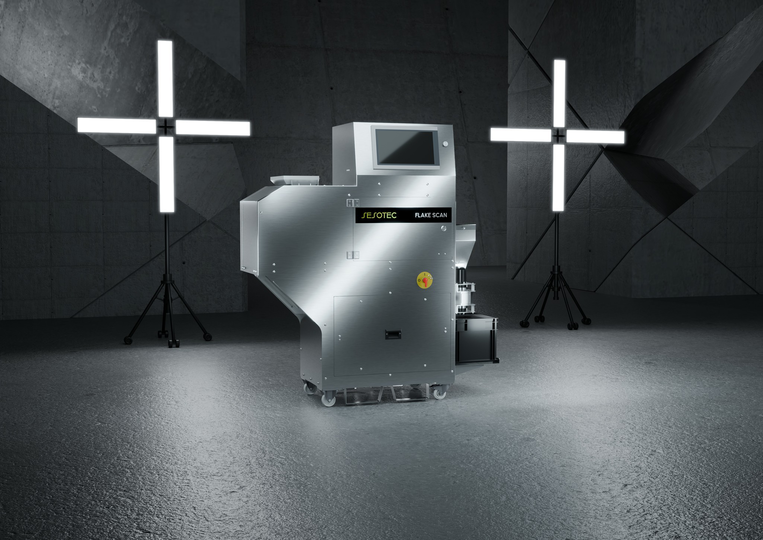

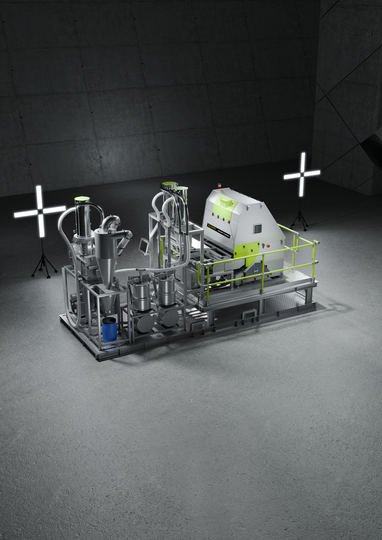

Material Management

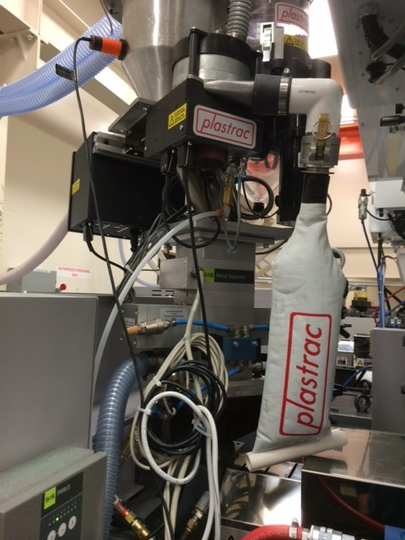

FLAKE SCAN and PRE-SORT systems ensure top-tier material quality for plastic processors.

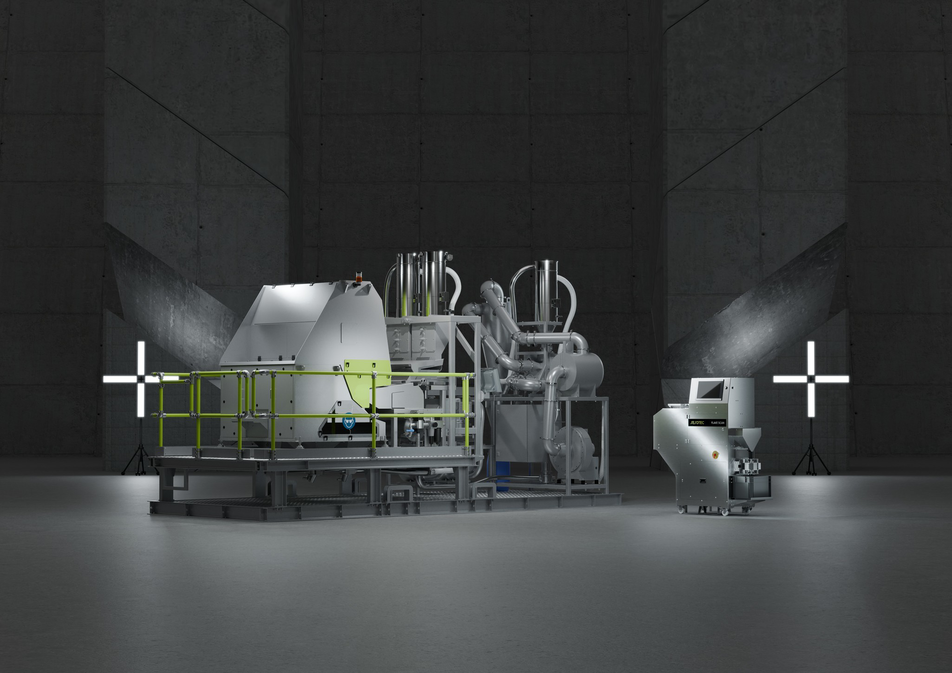

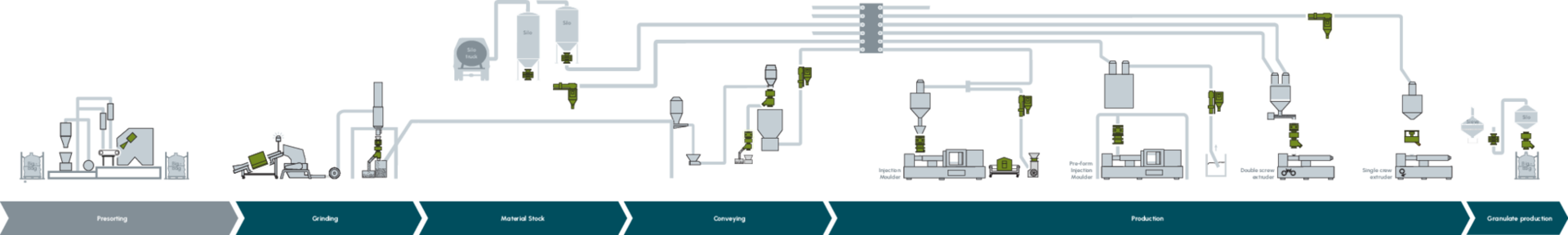

Where Are Sesotec Solutions Used in the Petrochemical Industry?

The applications are diverse. Some clients analyze their granules during production, such as after a screening machine. Others use our devices to ensure quality at the shipping stage, right before granules are packed into big bags, octabins, or similar containers.

Contact us – together, we'll find the perfect solution for your process layout!

Plastics

In plastic production, foreign body detection ensures high-quality end products and safeguards against material weaknesses.

Elastomers

Foreign body detection ensures that no unwanted particles enter the products, which could compromise their elasticity, strength, and durability.

Fibers

In fiber production, foreign body detection prevents metal particles in the product, ensuring consistent quality.

Across the Entire Production Line

Maximum security for your entire production: Our metal detection and magnet systems identify and remove foreign bodies throughout the production line. This ensures stable processes, compliant products, and high productivity—from material intake to the finished product.

Discover the Perfect Sesotec Solution Here

Interested?

ADD-ONS & SERVICES

Smart Add-ons for Enhanced Performance

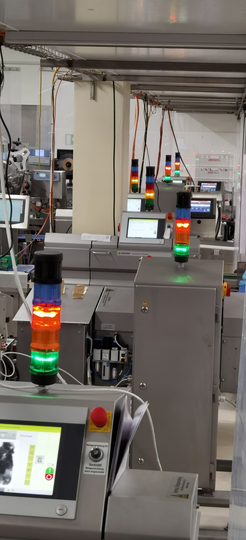

Insight.WEB, the visualization software for metal detectors, -separators and product inspection systems, brings transparency to your production processes, offering a clear overview for enhanced efficiency and increased profitability. Our smart machine monitoring reduces downtime and maximizes your OEE (Overall Equipment Effectiveness).

Centralized Control of

All Sesotec and Third-Party Devices

Clear Visualization & Control

of Your Processes

Maximize Profitability with

Data-Driven Process Optimization

We understand the challenges of petrochemicals.

Overall Equipment Effectiveness

Foreign bodies in production can lead to unexpected delays, increased maintenance, and reduced output.

Customer Demands and Quality

The petrochemical industry is under pressure to deliver plastic products of the highest purity and quality. Foreign bodies in the final product jeopardize customer satisfaction and can lead to complaints or loss of orders.

Avoid Production Downtime

Even small foreign bodies can halt production processes, leading to costly downtime and, in the worst case, the loss of entire batches.

Protect Your Machinery

Foreign bodies like metal parts or debris can damage sensitive production machinery. The result: High repair costs and production delays.

Sesotec has helped us not only optimize our internal processes but also enhance our reputation with end customers.

Read the Case Study

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.jpg)

.jpg)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.JPG)

.jpeg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.jpg)