METAL DETECTION FOR MATERIAL COLUMNS

Precise Metal Detection for Ultimate Material Purity

Even the smallest metal particles in plastic melt can cause costly disruptions in injection molding, extrusion, and blow molding. The risk increases with the growing use of regrind and recycled materials in the plastics processing and recycling industries. PROTECTOR metal separators remove metallic contaminants directly at the material feed above the machine – safely and reliably.

Who Benefits from Metal Detectors for Material Columns?

Metal detectors are strategically placed right before injection molding machines, extruders, and blow molding machines to inspect slow-moving or stationary material columns. They efficiently remove all magnetic and non-magnetic metals, even those embedded within the product, with minimal loss of good material.

Primarily for the plastics industry, especially for manufacturers and processors using granulate, regrind, or recyclate in injection molding, extrusion, or blow molding processes.

Magnets only remove ferromagnetic metals, while metal detectors can also identify and eliminate non-magnetic metals like stainless steel, aluminum, or brass. This ensures more comprehensive protection against contamination.

Eliminate Costly Disruptions

Eliminate Contaminants Right at Material Intake

Detect the tiniest metallic particles—even under heavy mechanical stress in high structures

Are you interested?

We see what you don't...

- Iron

- Steel

- Stainless Steel

- Non-Ferrous Metals

Common iron foreign bodies include machine parts, screws, nails, wires, or wear from conveyor belts and production equipment.

Plastic products can sometimes contain production residues like shavings, screws, or broken tools from mechanical processing.

Stainless steel often enters production through worn or damaged machine parts, pipelines, or cutting tools.

Aluminum, copper, or brass often come from packaging materials, cable scraps, pipelines, or machine wear parts.

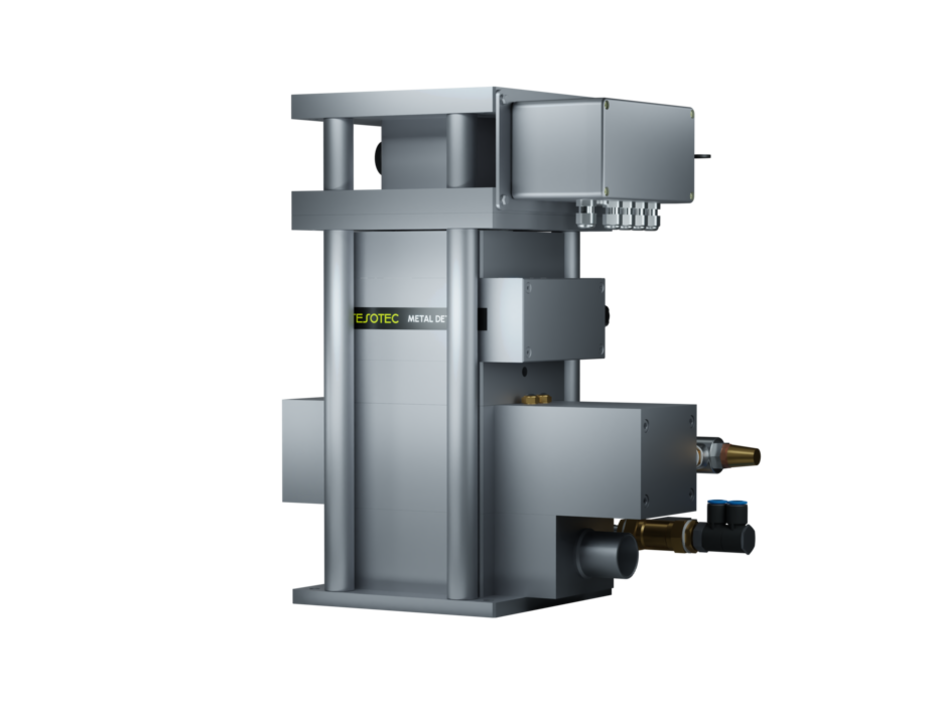

The PROTECTOR Family in Detail

Venturi Separation

Reduce installation height with vertical separation using a Venturi nozzle

Powerful, user-friendly Control Unit PRIMUS+

Intuitive interface with logbook feature

Compact Design

Seamless integration into existing production lines – even in tight spaces.

Low-Wear Venturi Nozzle

The Venturi principle generates a consistent airflow that gently transports materials and reduces buildup. This minimizes mechanical wear and extends the nozzle's lifespan.

Venturi Separation

Reduce installation height with vertical separation using a Venturi nozzle

Powerful, user-friendly Control Unit PRIMUS+

Intuitive interface with logbook feature

Compact Design

Seamless integration into existing production lines – even in tight spaces.

Low-Wear Venturi Nozzle

The Venturi principle generates a consistent airflow that gently transports materials and reduces buildup. This minimizes mechanical wear and extends the nozzle's lifespan.

We deliver the perfect solution for every application—standard or customized

Durability through

Quality "Made in Germany"

10 years of parts availability,

rapid service response times

Your Priorities - Our Solutions

- Material Efficiency

- Process Reliability

- Quality Assurance

Material Efficiency

Recyclers, plastic manufacturers, and processors face challenges with fluctuating material availability amid high demand. The higher the quality of the raw material, the more efficient the processing.

Process Reliability

Contaminated raw materials often lead to equipment failures and material waste. Advanced detection technologies ensure pristine raw materials, paving the way for smoother production.

Quality Assurance

Consistent product quality is the foundation of economic success. Streamlined production processes with minimal waste enhance your competitive edge.

0

Nominal Size0

Grain Size0

Installation HeightSmart Data Management for Enhanced Performance

Powerful sensor technology

The optional Monitoring Package with high-performance colour, humidity, and temperature sensors detects anomalies in the production process at an early stage.

Highest efficiency, highest profitability

- Increased machine protection and reduced downtime

- Consistently high product quality

- Analysis and display via dedicated dashboard

One Family - Diverse Solutions

Our material column metal detectors for the plastics industry

Brochure

Download

Discover comprehensive technical insights on our metal detection systems for material columns in our brochure.

ADD-ONS & SERVICES

Smart Add-ons for Enhanced Performance

The Monitoring Package ensures optimal rejection rates for surface search coil applications. Anomalies are reliably detected, elevating plastic processing in terms of machine protection and product quality to a new level.

Enhanced Machine Protection

& Reduced Downtime

Consistent

Product Quality

Analyze and display

with intuitive dashboards