Flat-Out Metal Detection

Our flat metal detectors seamlessly integrate into any production line handling bulk or piece goods. Installed beneath conveyors or chutes, they reliably detect all metallic contaminants, whether on the surface or embedded within the material.

Who Benefits from Flat Metal Detectors

For detecting metals in flat or wide materials such as web goods, flat bulk items, or bulk goods with low conveying height.

Flat metal detectors are widely used in the plastics, wood, construction, and textile industries.

A flat metal detector is perfect for products that can't pass through a tunnel, such as bulky or large-surface materials.

Detect the smallest metal parts—even with wider probe widths

Minimal Disruption

Effortless Installation in Conveyors and Chutes

Interested?

We see what you can't...

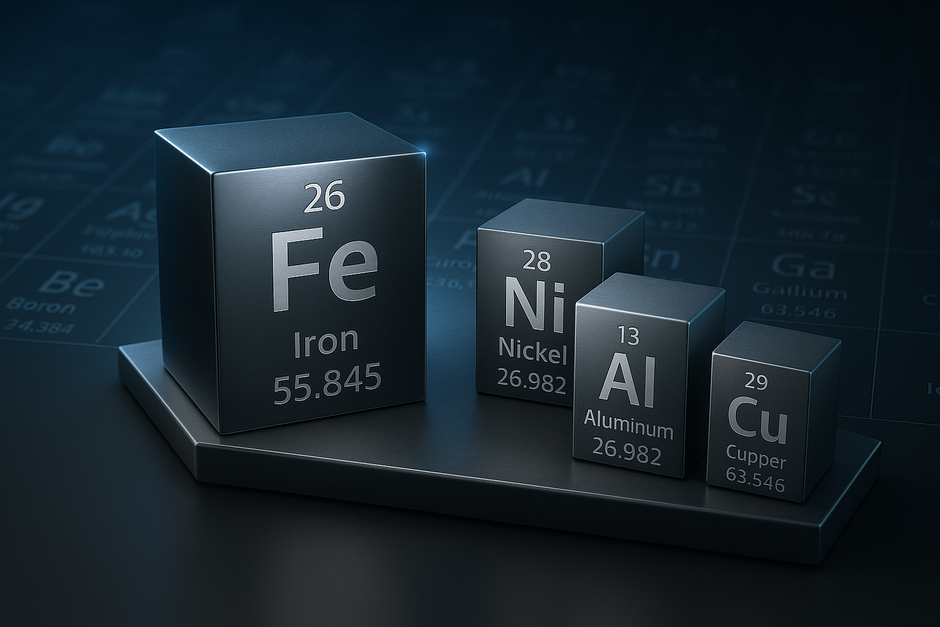

- Iron

- Steel

- Stainless Steel

- Non-Ferrous Metals

Common iron foreign bodies include machine parts, screws, nails, wires, or wear from conveyor belts and production equipment.

Steel can enter the product through worn machine parts, tool breakage, or metallic abrasion particles.

Stainless steel often enters production through worn or damaged machine parts, pipelines, or cutting tools.

Often originate from packaging materials, cable remnants, pipelines, or machine wear parts

Our Flat Metal Detectors in Detail

Intuitive and user-friendly

Quick setup and effortless adaptation to various products with Control Unit Primus+

Effortless Installation

Quick and easy integration into existing production lines – no extensive modifications needed.

IoT-Ready

Seamless integration into networks for remote monitoring and data analysis with an optional Ethernet interface.

Durable Design

Reliable performance with a durable casing – even in demanding industrial environments.

Intuitive and user-friendly

Quick setup and effortless adaptation to various products with Control Unit Primus+

Effortless Installation

Quick and easy integration into existing production lines – no extensive modifications needed.

IoT-Ready

Seamless integration into networks for remote monitoring and data analysis with an optional Ethernet interface.

Durable Design

Reliable performance with a durable casing – even in demanding industrial environments.

We deliver the perfect solution for every application—standard or customized

Durability through

Quality "Made in Germany"

10 years of parts availability,

rapid service response times

Your Priorities - Our Solutions

- Material Efficiency

- Process Reliability

- Quality Assurance

Material Efficiency

Processors of bulk and piece goods, such as those in the wood, textile, construction, and plastics industries, face challenges with fluctuating material availability during high demand periods. The higher the quality of the raw materials, the more efficient the subsequent processing.

Process Reliability

Contaminated raw materials often lead to equipment failures and material waste. Advanced detection technologies ensure pristine raw materials, resulting in smoother production.

Quality Assurance

Consistent product quality is the foundation of economic success. Optimized production processes with minimal waste enhance your competitive edge.

Innovative Detection Technology...

Reliable detection of magnetic and non-magnetic metal contaminants for diverse industries.

...with auto-learn capability

for optimal adaptation to the inherent conductivity of the product being tested, ensuring a lower false reject rate.

One Family - Diverse Solutions

Flat metal detectors for bulk or packaged goods

Brochure

Download

Discover comprehensive insights and all the technical specifications of our flat metal detectors in our brochure.

ADD-ONS & SERVICES

Smart Add-ons for Enhanced Performance

Insight.WEB, the visualization software for metal detectors, -separators and product inspection systems, brings transparency to your production processes, offering a clear overview for enhanced efficiency and increased profitability. Our smart machine monitoring reduces downtime and maximizes your OEE (Overall Equipment Effectiveness).

Centralized Control of

All Sesotec and Third-Party Devices

Clear Visualization & Control

of Your Processes

Maximize Profitability with

Data-Driven Process Optimization