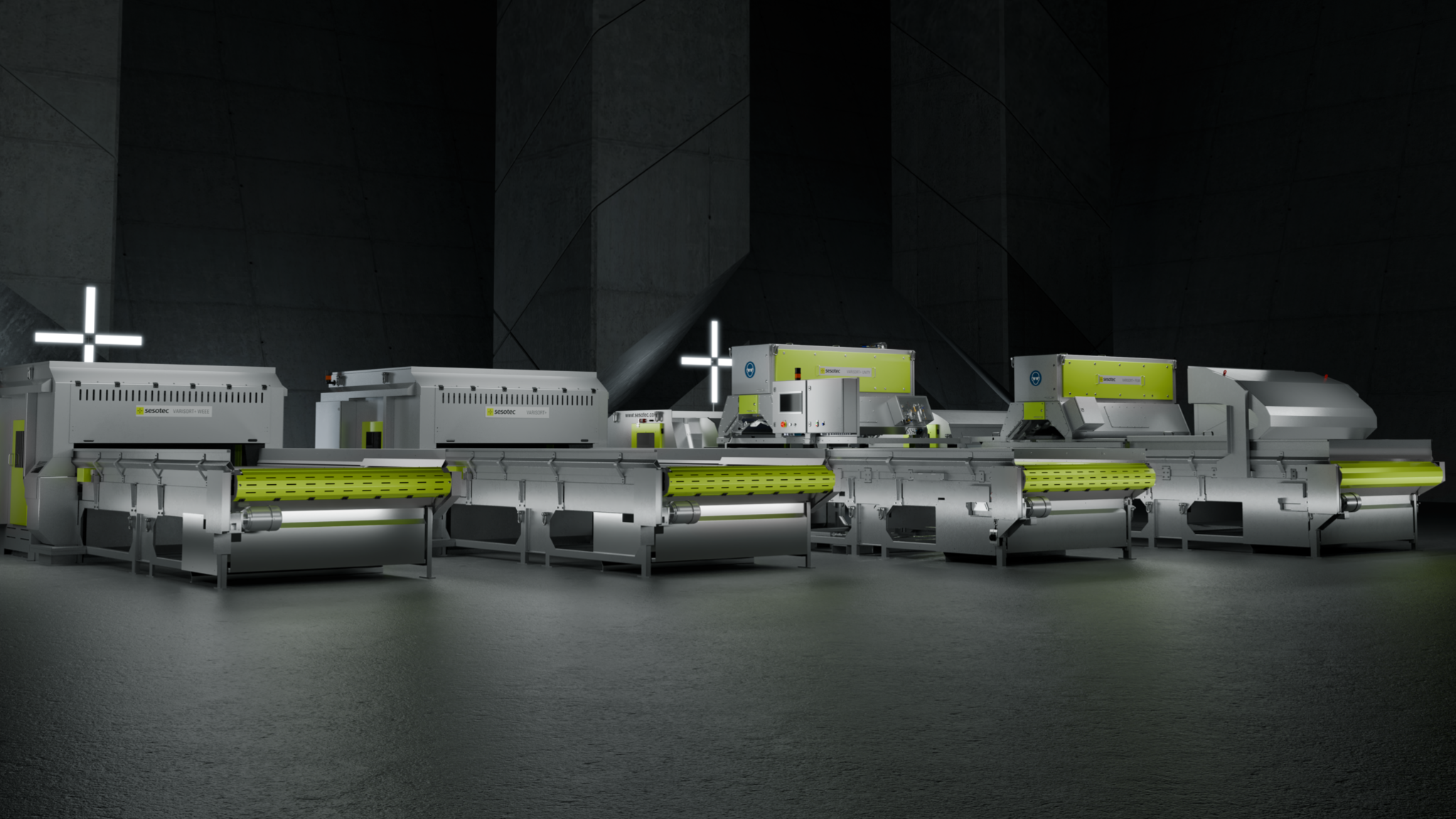

RECYCLING SORTING SYSTEMS

Greater Purity, Higher Yield

Our conveyor-based recycling sorting systems are true multitaskers: they separate plastics as precisely and effectively as glass, metals, e-waste, or household waste.

With their modular design, various sensors can be customized to fit your needs.

Who Benefits from Conveyor Belt Sorting Systems?

A conveyor-based sorting system is essential for efficiently handling high volumes, automating separation by size, weight, or material, and overcoming the limitations of slow or error-prone manual sorting.

Sorting systems with conveyor belts are ideal for recycling plastics, lightweight packaging, PET, metals, e-waste, and household waste.

Slides are perfect for materials like flakes, regrinds or glass cullet. Conveyors are ideal for high-volume, mixed material streams such as plastic packaging, metal scrap, or e-waste.

Unmatched Precision at High Speeds

Achieve optimal sorting results – even with low-quality materials

Combine up to three sensors for diverse applications

Interested?

We separate what doesn't belong together…

- PET Recycling – Plastic Bottles

- Mixed Plastics & Household Waste Recycling

- Plastic Recycling

- Metal Scrap Recycling

- E-Waste Recycling

Organic materials, metals, or other types of plastics complicate the sorting and recycling of PET bottles.

Organic waste, glass, or metals hinder the separation and recycling of vital raw materials from mixed waste.

Metal parts or non-recyclable plastics (e.g., PVC) can disrupt recycling processes and reduce the quality (purity) of recyclates.

Plastic or electronic components must be removed to obtain pure metals.

Batteries, hazardous components, or non-separable material composites demand specialized sorting processes.

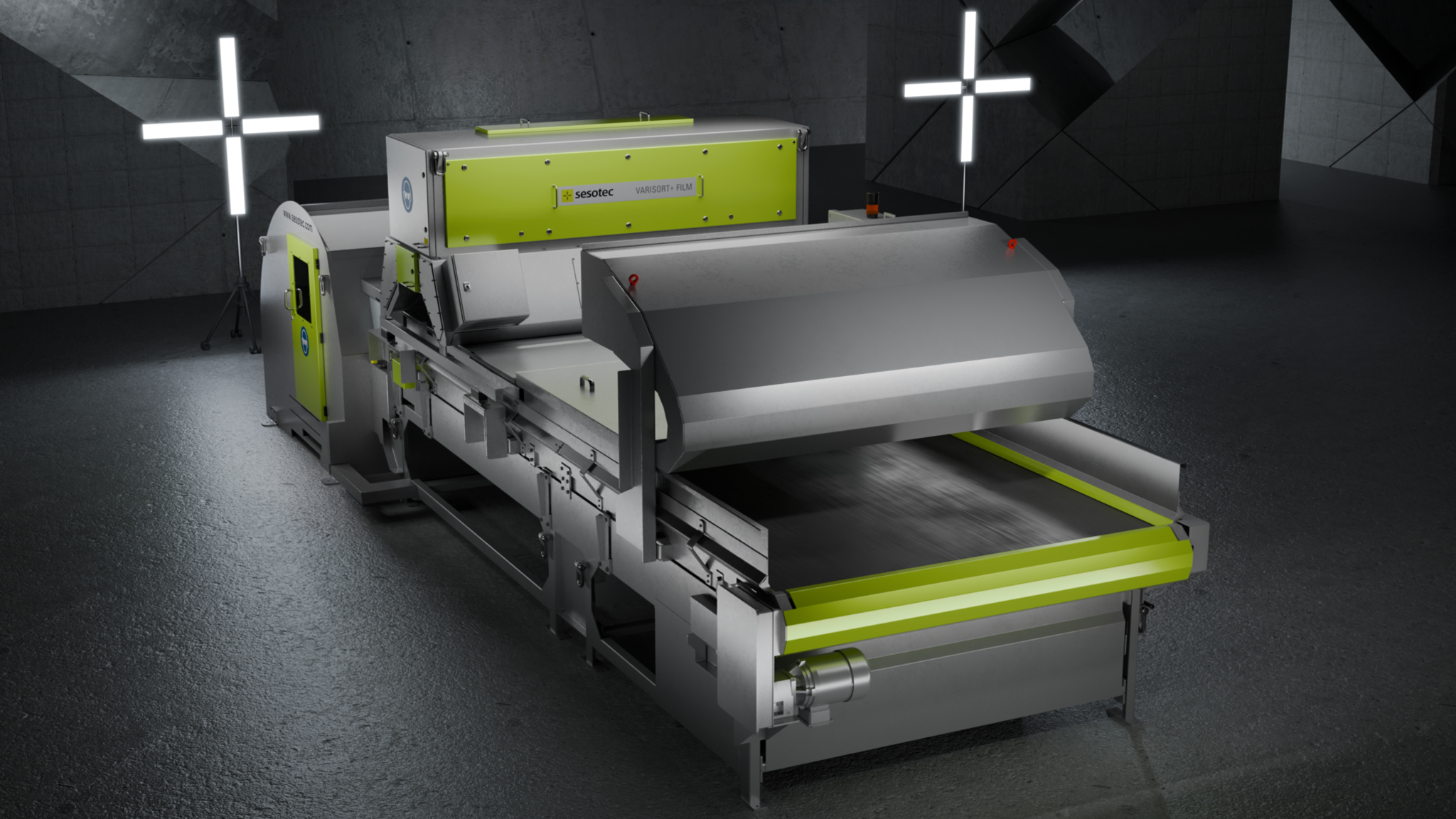

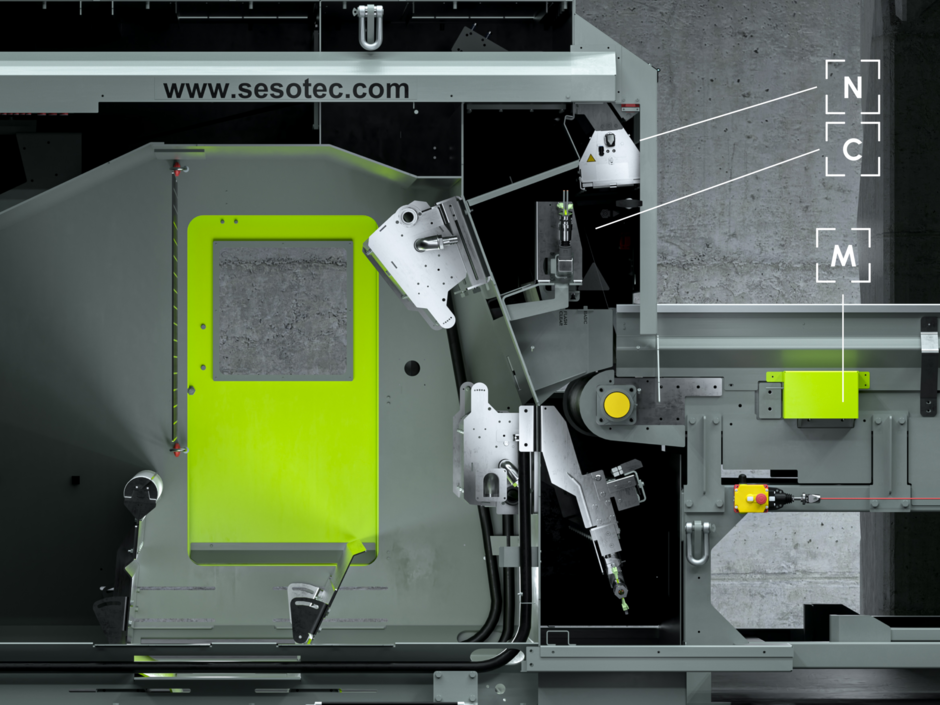

VARISORT+ in Detail

Optimized Machine Design

Engineered for high throughput, easy cleaning, low maintenance, and maximum uptime.

High-Speed Conveyor Belt

Efficient material distribution and high throughput with speeds up to 4 m/s.

Flexible Sensor Combination

Color and shape sensor, all-metal sensor, near-infrared sensor (NIR)

Ejection Housing with Blowout System

Achieve precise separation of foreign bodies, material types, colors, and shapes with targeted air blasts using various nozzle grids for exceptional sorting accuracy.

Optimized Machine Design

Engineered for high throughput, easy cleaning, low maintenance, and maximum uptime.

High-Speed Conveyor Belt

Efficient material distribution and high throughput with speeds up to 4 m/s.

Flexible Sensor Combination

Color and shape sensor, all-metal sensor, near-infrared sensor (NIR)

Ejection Housing with Blowout System

Achieve precise separation of foreign bodies, material types, colors, and shapes with targeted air blasts using various nozzle grids for exceptional sorting accuracy.

We deliver the perfect solution for every application—standard or customized

Durability through

Quality "Made in Germany"

10 years of parts availability,

rapid service response times

Your Priorities, Our Solutions

- Material Efficiency

- Process Reliability

- Quality Assurance

Material Efficiency

Recyclers, plastic manufacturers, and processors face fluctuating material availability amidst high demand. The higher the quality of the raw material, the more efficient the processing.

Process Reliability

Contaminated raw materials often lead to equipment failures and material waste. Advanced detection technologies ensure pristine raw materials, paving the way for smoother production.

Quality Assurance

Consistent product quality is the foundation of business success. Streamlined production processes with minimal waste enhance your competitive edge.

0

Belt Speed0

Throughput0

Exit Security

Maximize Uptime

Durable design and optimized components reduce maintenance and downtime, ensuring reliable continuous operation.

Up to 7 Sensor Combinations

Achieve ultra-precise sorting with our advanced combination of color (C), near-infrared (N), and metal sensors (M).

Compact Combination System

VARISORT COMPACT is engineered specifically for sorting three-dimensional materials and e-waste. Its standout feature is the integration of a feed chute with a conveyor belt.

Sesotec sorting systems leverage AI and cutting-edge sensors to differentiate and sort materials previously indistinguishable.

NIR-AI

For precise differentiation, the point clouds defined by the spectral analysis of the near-infrared sensor must be clearly distinct. When significant overlaps occur, as shown in the image on the left, the risk of misidentification increases. This leads to the loss of valuable resources for recycling. A typical challenge for NIR sensors: Monolayer and Multilayer PET.

OBJECT-AI

Harnessing Artificial Intelligence, our Color Sensor assigns specific attributes to each object through color and shape analysis. This ensures precise classification and differentiation of good and defective materials based on shape, color, and texture (bounding boxes).

One Product Family – Diverse Solutions

Our Conveyor Belt Recycling Sorting Systems

Brochure

Download

Discover a comprehensive overview of our conveyor belt recycling sorting systems, complete with all technical specifications, in our brochure.

ADD-ONS & SERVICES

Smart Enhancements for Unmatched Performance

Unlock actionable insights from process data to boost the efficiency of your sorting and recycling operations and minimize downtime. VISUDESK, the visualization software for sorting machines and systems, brings transparency to your sorting processes with process data, enabling direct control for enhanced efficiency and profitability.

Enhance Clarity in

Your Sorting Processes

Unleash Total Control

Over Your Sorting Systems

Boost Profitability with

Data-Driven Optimization