We Drive Purity

Clogged hot runners, broken extruder screws, or shattered blades in shredders: Metallic contaminants cause numerous issues in plastic processing. We offer the right foreign body detectors to identify and remove metals, preventing machine damage and production downtime. This not only enhances your product quality but also boosts overall equipment effectiveness.

Why Choose Product Inspection?

Just like recyclers, plastic manufacturers and processors face challenges with the fluctuating availability of recycled material—especially during high-demand periods. It's not just about quantity; the quality of purchased material must also meet processing standards. The better the raw material, the more efficient the entire process. This is where Economy meets Ecology: High-quality recycled material conserves resources, reduces waste, and enhances production profitability.

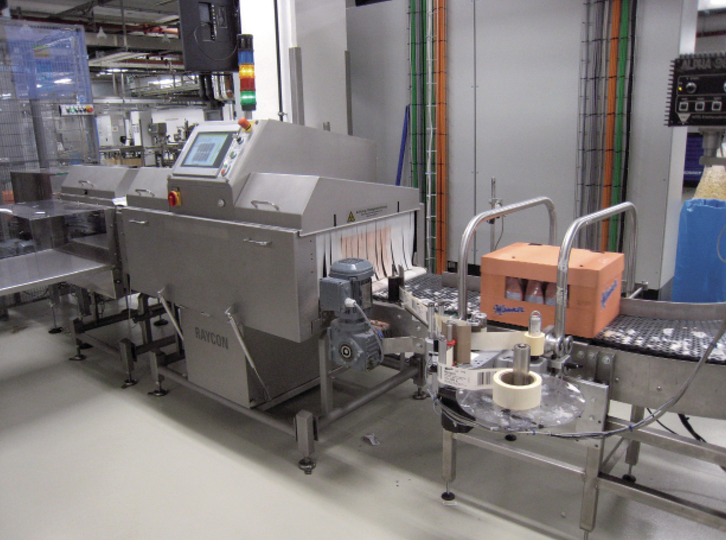

The plastics, rubber, and chemical industries often rely on expensive equipment like injection molding machines, calenders, extruders, or blow molding machines. Their continuous operation is crucial for the company's profitability. However, even the smallest metal parts can disrupt this process by clogging melt filters, hot runners, and nozzle tools, blocking non-return valves, or damaging screws and cylinders. To prevent this, the use of metal detectors and separators is recommended: By detecting and removing foreign bodies in time, process continuity and productivity are enhanced.

Product purity is a crucial quality benchmark. Metal contaminants can cause blockages in production equipment, leading to defects in plastic components. In sectors like hygiene products, consumer protection underscores the necessity of avoiding metal impurities. Using metal detectors can reduce waste, prevent complaints, and boost customer satisfaction.

No more broken machines due to contaminated plastic material

Does that sound good to you?

YOUR INDUSTRY

Tailored Solutions for Every Sector of the Plastics Industry

Material and purity are crucial on the path to a circular economy. With smart technologies and services, we empower manufacturers, processors, and recyclers of plastics to produce in a circular and highly efficient manner. This way, profitability, sustainability, and environmental protection go hand in hand.

Enhanced Security, Fewer Hassles

25

Days

Production downtime caused by machine damage – triggered by contaminated material

300

Thousands of €

Boost your production value by reducing maintenance from 25 to 16 days annually with Sesotec metal detectors

With our solutions for the plastics industry, metal contamination is a thing of the past.

Remove Everything That Doesn't Belong

- Wear and abrasion

- Broken Blades

- Accidental Contamination

- Contaminated Input Material

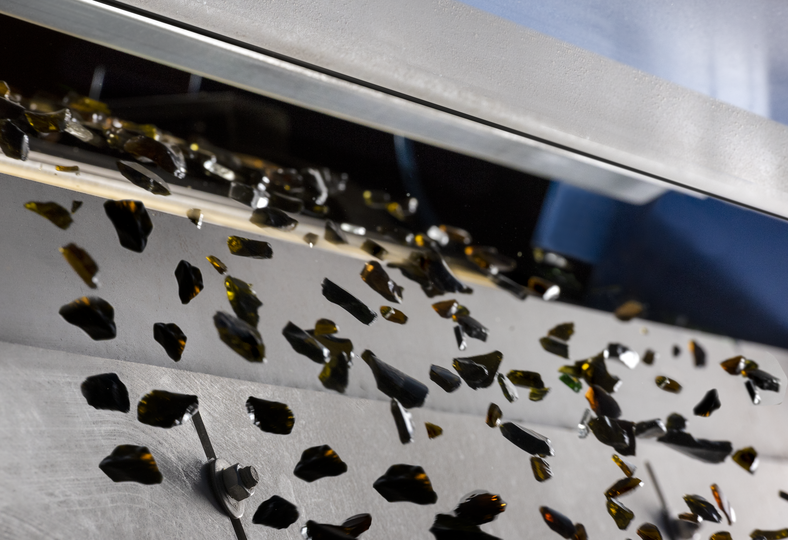

When conveying and processing abrasive plastic materials, abrasion can occur in conveying pipes and wear can affect machines. As a result, tiny metal particles may come loose, enter the product batch unnoticed, and compromise the quality and safety of the manufactured plastic products.

Broken blades during hot or cold trimming can leave sharp fragments that infiltrate plastic products unnoticed, compromising product integrity and safety in further processing.

(e.g. through openings in silos)

When opening silos, foreign bodies like personal items from staff can unintentionally enter the production process.

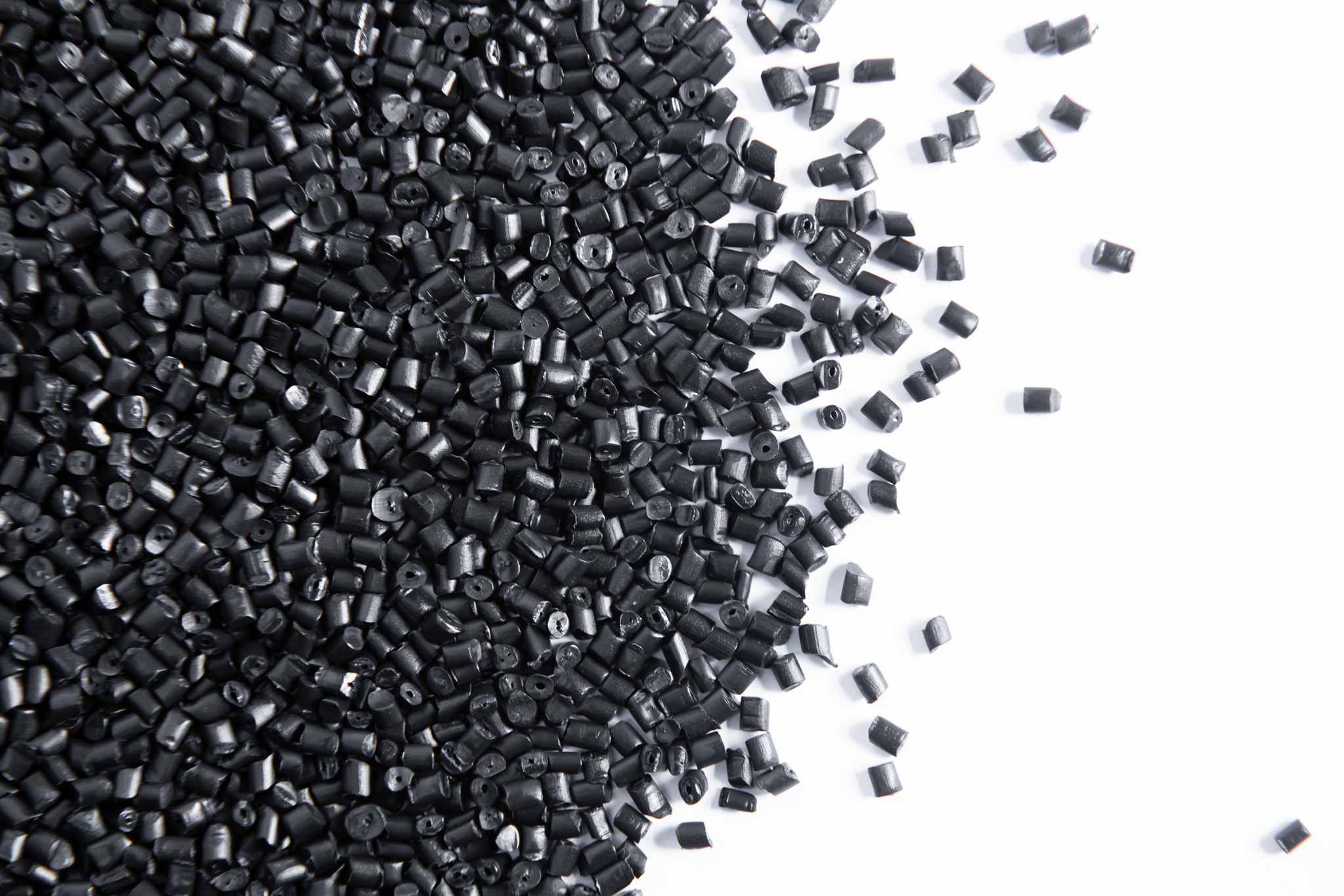

(Granules, Recyclate, Additives)

Impurities in raw materials can cause significant quality issues, including reduced strength, unwanted color effects, or even structural weaknesses in the final product.

Closing the Plastics Cycle

The plastics industry is under pressure: climate change, the waste of finite resources, and the vast amounts of plastic in our oceans are in the spotlight for governments, businesses, and society. The concept of a sustainable circular economy presents diverse challenges for manufacturers, processors, and recyclers of plastics, but it also offers numerous opportunities.

Sustainable yet Efficient

To achieve optimal profitability in the circular economy, it's crucial for plastic manufacturers, processors, and recyclers to equip their facilities with flexible technology. A precisely tuned and well-thought-out combination of metal separators and sorting systems ensures equipment availability and actively boosts efficiency.

Cutting-Edge Technology for the Plastics Industry

Modular Solutions for Every Application

No matter your sector in the plastics industry or the specifications your machines require, our technology empowers you to overcome every challenge in foreign body detection during plastic production.

- Metal Detection

- Sorting Systems

- Magnets

- Material Management

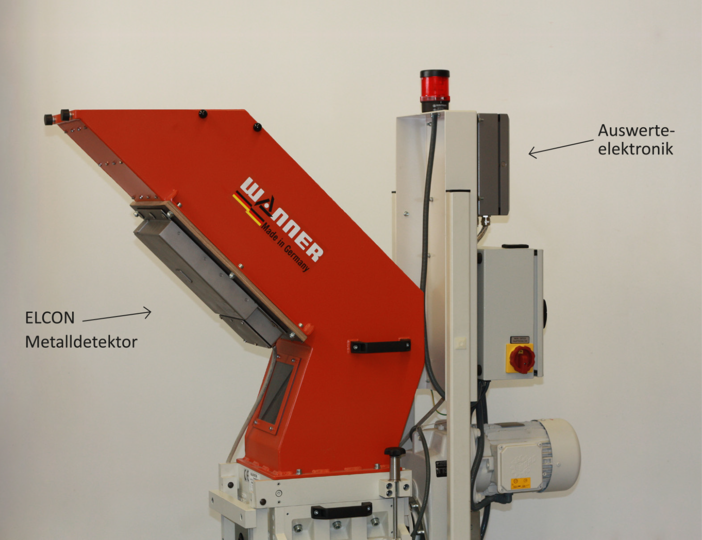

Metal Detection

Whether the contamination is from iron, steel, stainless steel, or non-ferrous metals like aluminum, copper, and brass, and whether it's exposed or embedded in the product: Our metal detection systems, using inductive technology, identify all metallic foreign bodies. They send a signal to the process control and, in conjunction with a separating unit, automatically remove the contaminated products.

READ MORE

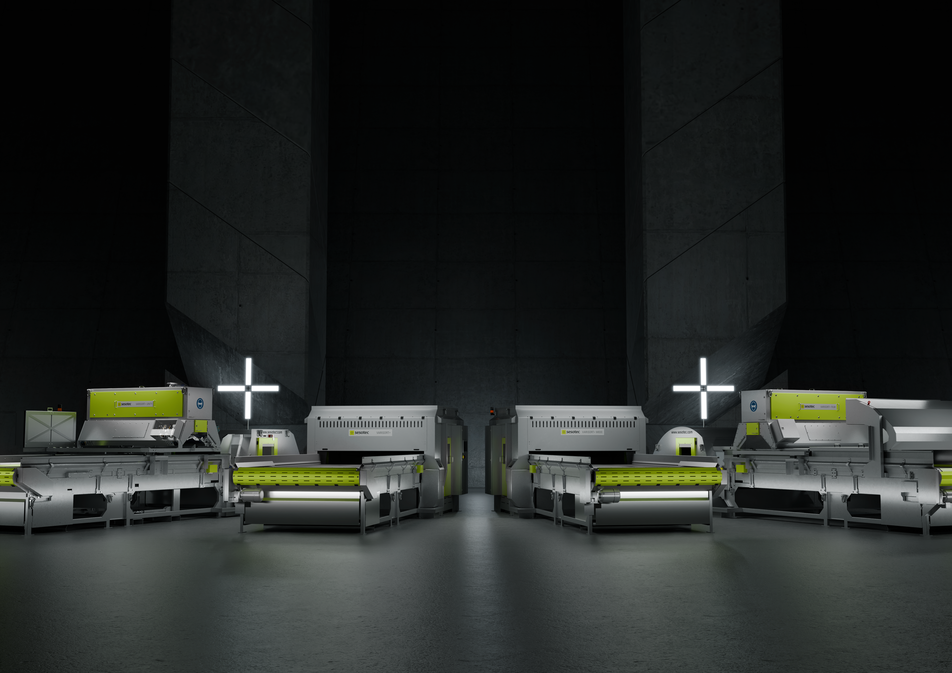

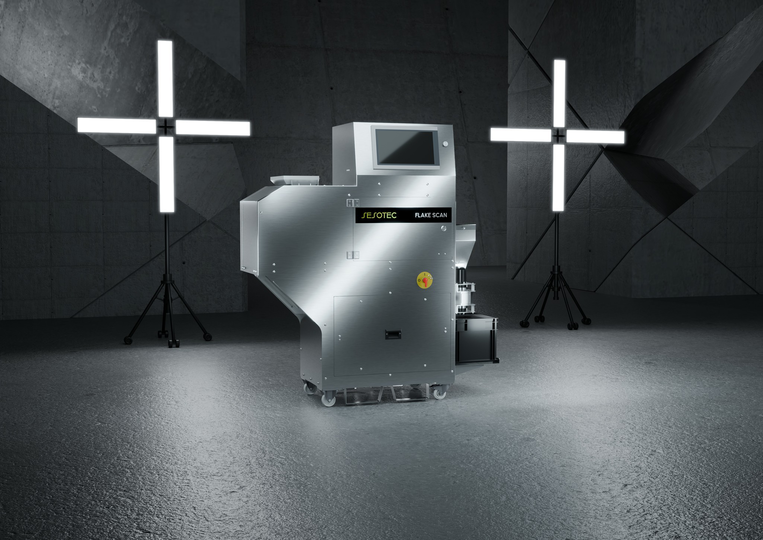

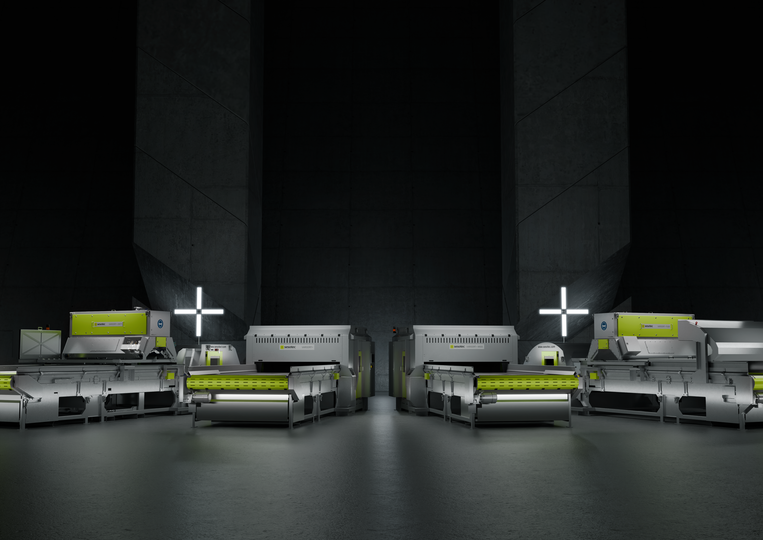

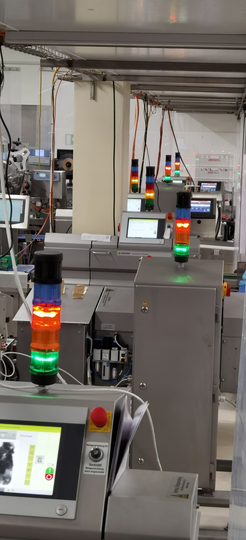

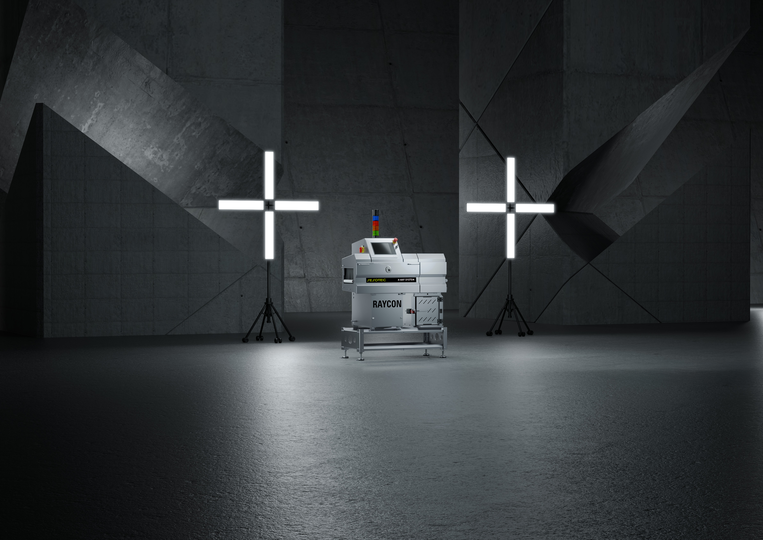

Sorting Systems

Our sorting machines are modular by design: Tailored to your specific needs, we integrate various sensors, detectors, and separators into a single unit. Unwanted materials are precisely removed from the material flow in milliseconds using advanced separation systems like air jets and flaps.

READ MORE

Magnets

Our magnetic systems deliver exceptional magnetic performance and efficient design to eliminate even the finest ferrous metal contaminants. Staggered magnetic bars achieve maximum separation efficiency. They are easy and quick to integrate into piping systems, hoppers, or directly at material inlets—even in existing production lines.

READ MORE

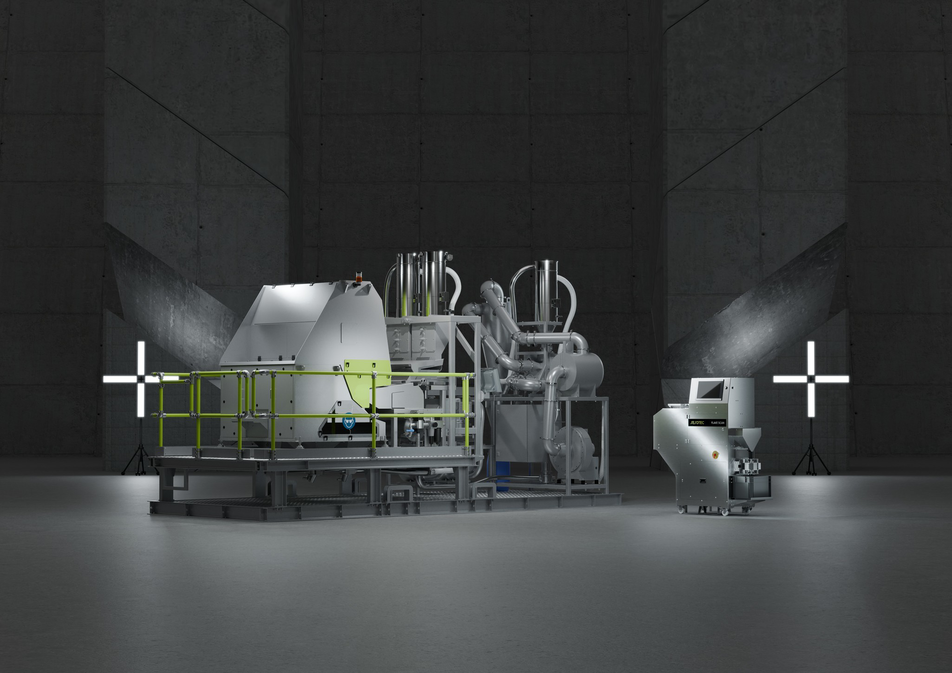

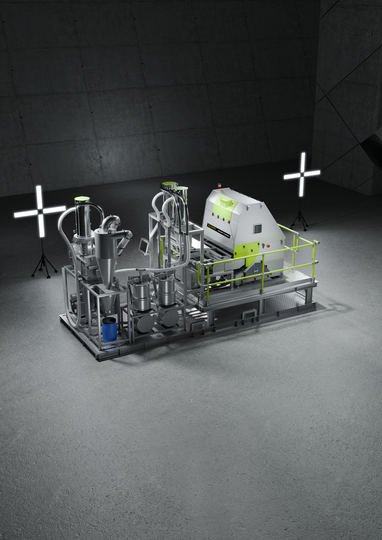

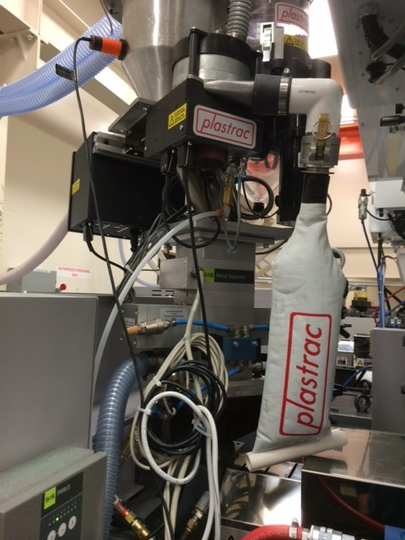

Material Management

Returning recyclates and regrind to the plastics loop is the goal of sustainable production. However, inconsistent quality complicates processing. By analyzing at the point of entry or exit, planning becomes reliable. Mobile processing enhances subpar recyclate – boosting efficiency and profitability.

READ MORE

ADD-ONS & SERVICES

Smart Add-ons for Enhanced Performance

Insight.WEB, the visualization software for metal detectors, -separators and product inspection systems, brings transparency to your production processes, offering a clear overview for enhanced efficiency and increased profitability. Our smart machine monitoring reduces downtime and maximizes your OEE (Overall Equipment Effectiveness).

Centralized Control of

All Sesotec and Third-Party Devices

Clear Visualization & Control

of Your Processes

Maximize Profitability with

Data-Driven Process Optimization

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.jpg)

.jpg)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.JPG)

.jpeg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.jpg)