Uncompromising Quality

In food production, every detail matters. Even the slightest contamination can jeopardize your product quality.

Don't settle for less in product inspection: Sesotec's inspection systems detect what the eye can't see – safeguarding your brand, your customers, and your production processes.

We see what you don't...

- Metal foreign bodies

- Non-metallic foreign bodies

- Plastics

- Elastomers

Metallic foreign bodies, such as lead, copper, brass, stainless steel, iron, or aluminum, can be detected in food and then removed.

In addition to metallic objects, non-metallic foreign bodies such as ceramics, stones, glass, wood, or bones are also detected by product inspection systems.

Even in food products, plastics like PVC, Teflon, PA, PE, PP, or Nylon can enter during production.

...as used in the production of car tires

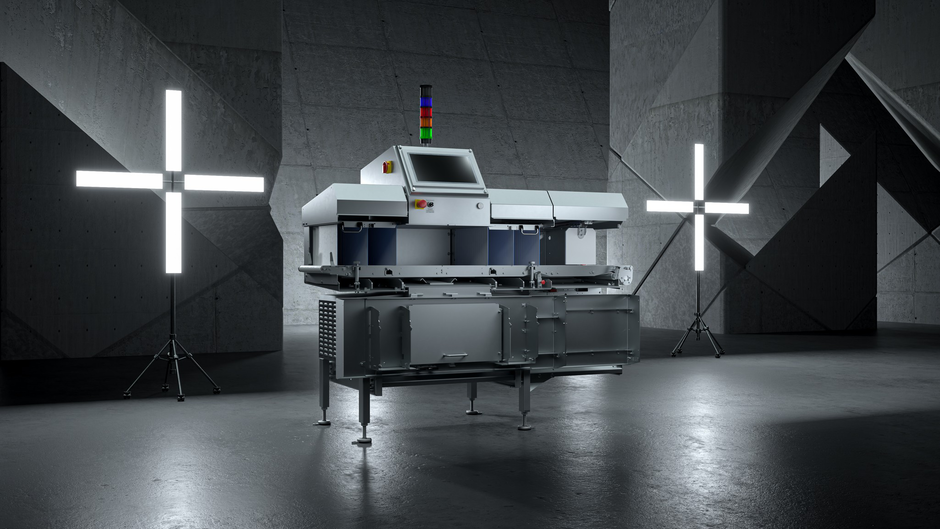

Product Inspection Systems for the Highest Standards

Discover Our Product Families

Discover the Power of Our Product Inspection Systems

Our inspection systems detect all relevant foreign bodies in food production from a particle size of 3 mm.

Sesotec's product inspection systems detect even the smallest metallic and many other foreign bodies, ensuring that only top-quality products reach your customers.

With THiNK, the AI-powered software for Sesotec product inspection systems, you can significantly enhance bone detection and anomaly discovery.

Sesotec's product inspection systems ensure compliance with all relevant industry norms and standards, such as IFS, BRC, and FSMA.

How Sesotec Product Inspection Systems Work

Modular Design

Sesotec X-ray product inspection systems adapt flexibly to your unique requirements. Modifications and upgrades are always possible—ensuring maximum efficiency and future-proofing your production.

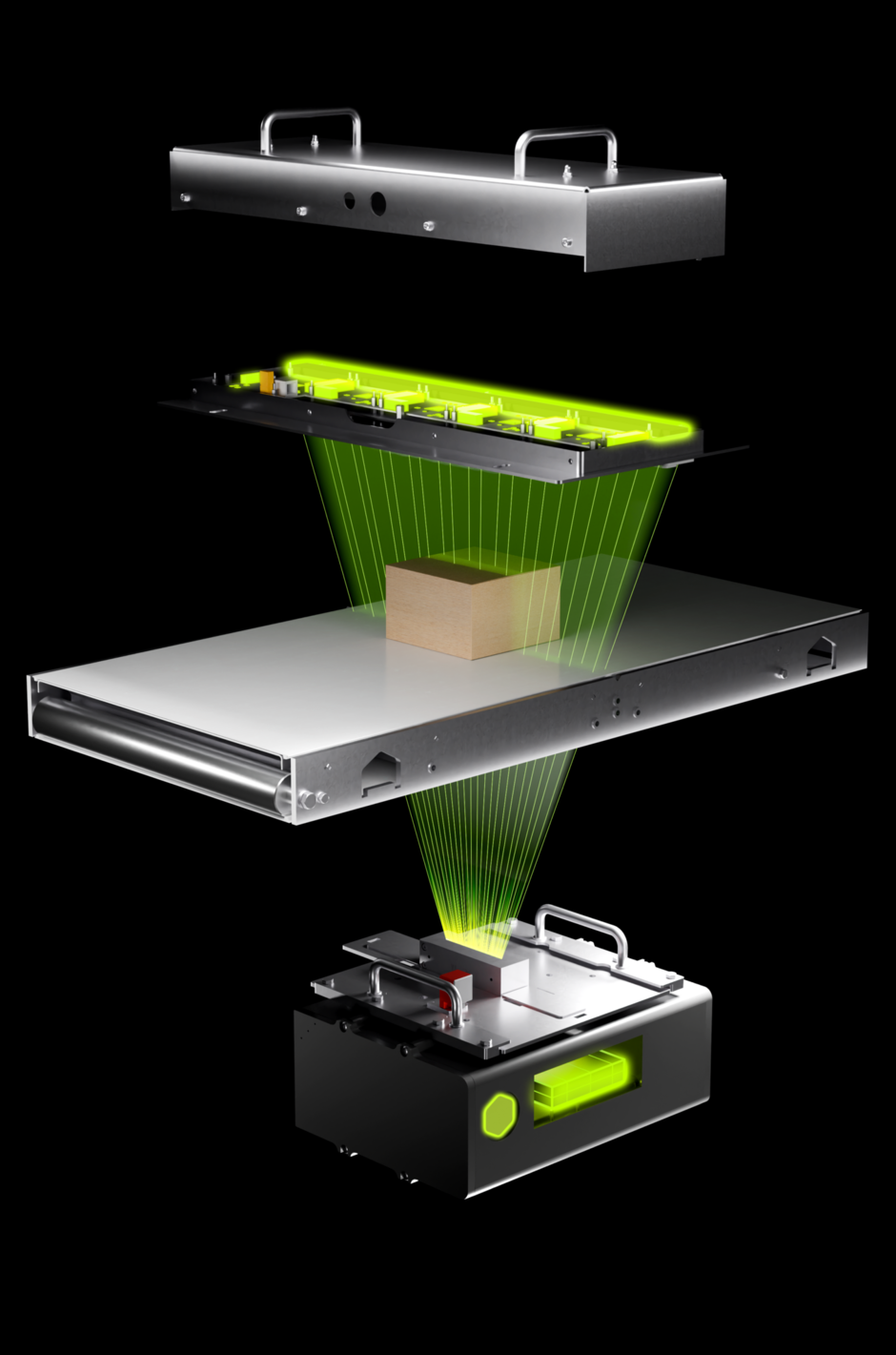

Bottom-Up Technology

The bottom-up funnel-shaped expansion of the X-ray beam magnifies foreign bodies in the detector. This allows a 0.8 mm detector to identify foreign bodies as small as 0.6 mm. In RAYCON devices, the X-ray source is positioned below the conveyor belt, eliminating blind spots even with tall products.

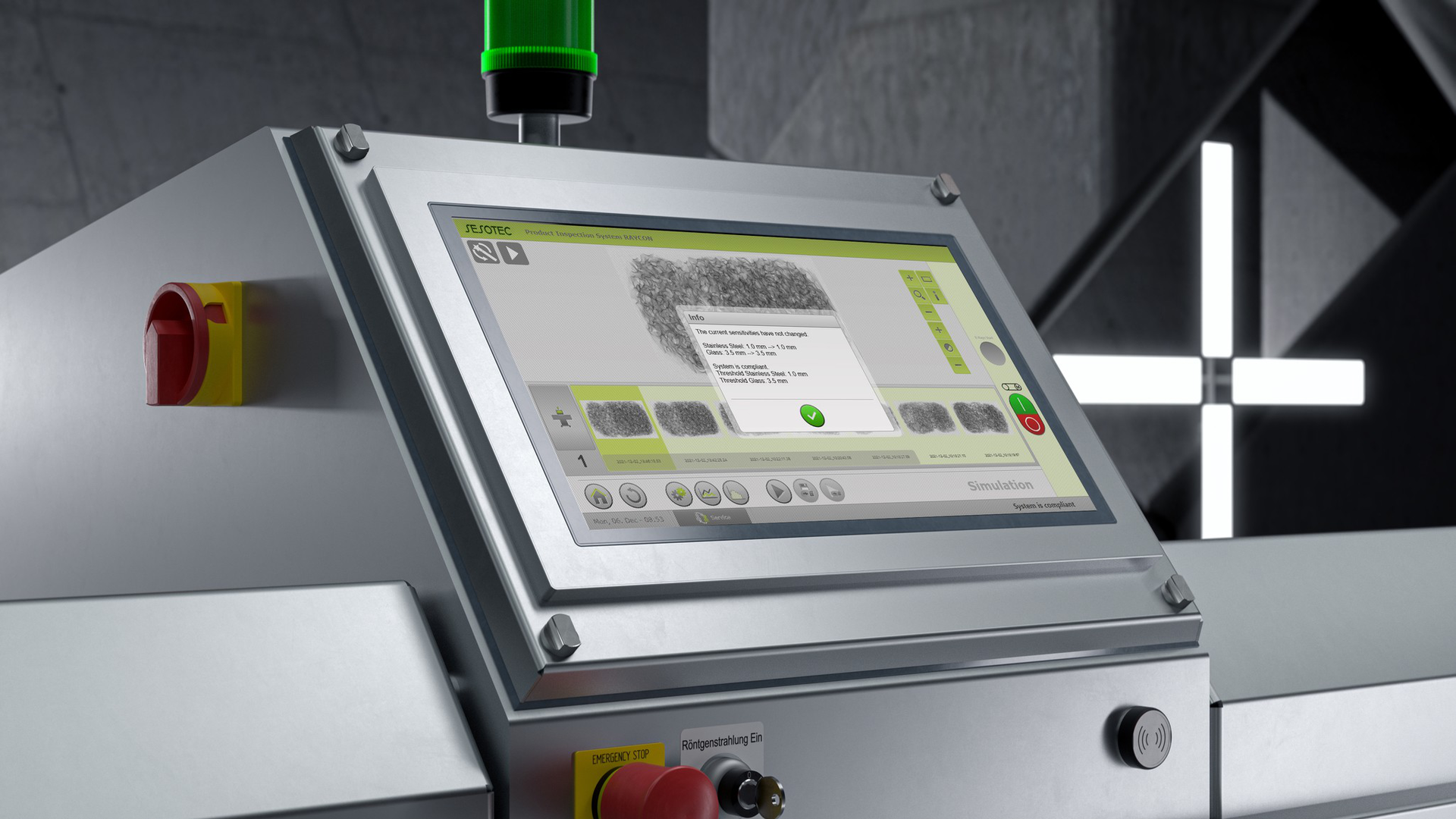

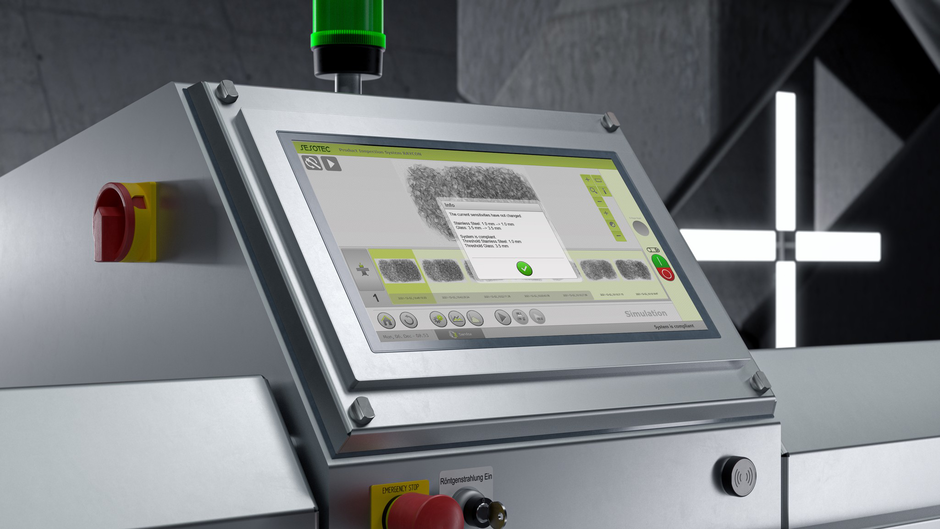

Compliance – Anytime, Anywhere

The Compliance Package, available for all Sesotec systems, ensures seamless and efficient documentation of your production process – featuring Audit Check, Sensitivity Prediction, Compliance Mode, Integrated Compliance Monitoring, and Integrated Validation Process.

0

mm detection accuracy0

Meters per Second0

Service Days Per Year0

Products per MinuteX-ray Inspection with Sesotec – Simply Explained

ADD-ONS & SERVICES

Smart Add-ons for Enhanced Performance

Insight.WEB, the visualization software for metal detectors, -separators and product inspection systems, brings transparency to your production processes, offering a clear overview for enhanced efficiency and increased profitability. Our smart machine monitoring reduces downtime and maximizes your OEE (Overall Equipment Effectiveness).

Centralized Control of

All Sesotec and Third-Party Devices

Clear Visualization & Control

of Your Processes

Maximize Profitability with

Data-Driven Process Optimization

THiNK - X-ray Inspection with Artificial Intelligence

AI-Driven Anomaly Detection

Detect contaminants that barely differ in grayscale from the perfect product—impossible with traditional methods, but achievable with THiNK.

AI-Powered X-Ray Vision

Experience the next generation of product safety: Our adaptive AI software, THiNK, virtually eliminates the product effect, enabling the effective detection of even the smallest foreign bodies. The benefits for you: fewer false rejects, fewer product recalls, less hassle. THiNK also works with metallized packaging.