In the idyllic St. Stefan im Rosental, in the heart of Southeast Styria, lies the home of Loidl Salami. Founded in the 1960s, H. Loidl Wurstproduktions- und Vertriebsges. m.b.H & Co KG owes its rapid growth to the highest quality of its products. Behind the excellent taste is a combination of craftsmanship and technical control.

The problem: Residues of aluminum clips in the salami

After cutting, carefully mixing all the ingredients, the sausage is filled into a breathable casing and sealed on both sides with aluminum clips. The salamis are then hung in the ripening chamber and remain there for up to three months. When the fully matured Loidl salami is cut and packaged, the casing and aluminum clips must first be removed by hand. Occasionally, aluminum residues remain on the salami, and since the standard metal detectors used up to that point could not achieve the required sensitivities, Loidl asked Sesotec for an alternative solution to detect aluminum clip parts in unpackaged salami sticks with lengths of 50 to 60 centimeters and automatically remove contaminated products. Attention quickly turned to methods of Artificial Intelligence (AI), which Sesotec was researching at the time of the project with Loidl. During the development of the AI software "THiNK," a partnership collaboration was formed with Loidl.

.jpg)

The solution: Metal detection with artificial intelligence for products with high product effect

Due to the inherent conductivity (product effect) of meat, it is difficult to find metallic foreign bodies with conventional metal detection systems. The THiNK software from Sesotec, used in INTUITY metal detectors, makes it possible to solve this problem.

With THiNK technology, multiple frequencies are applied simultaneously to the product being examined. The product effect can thus be more narrowly defined, resulting in multiple "intelligent" detection thresholds. All signals outside the thresholds are recognized as metallic foreign bodies, and the sensitivity is significantly increased. THiNK significantly improves metal detection performance because a high sensitivity setting is possible to find the smallest metallic particles.

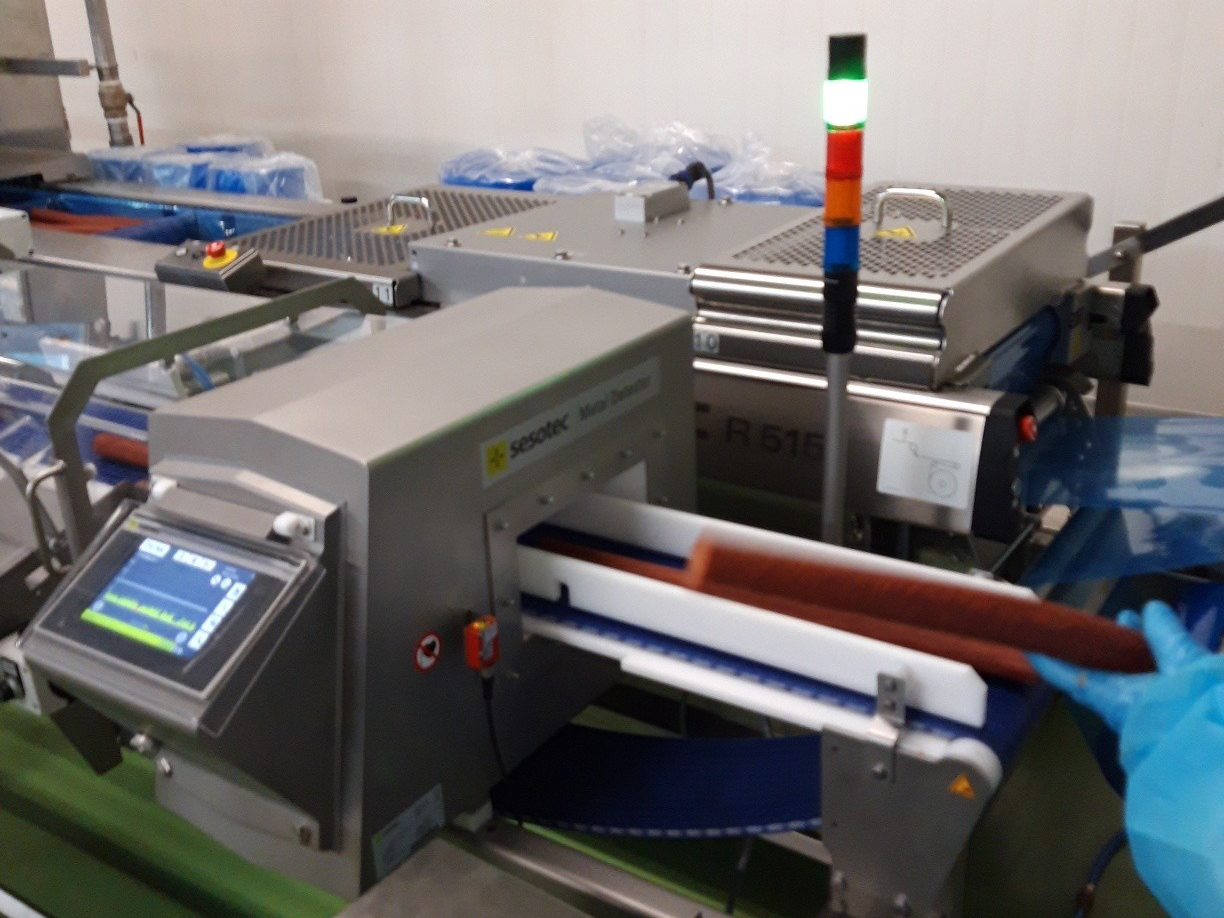

With THiNK, the product effect can be almost completely eliminated, meaning the product effect is distinguished from actual metal contaminants. This minimizes false rejections while simultaneously increasing sensitivity. To find the best setting, tests were conducted at the Sesotec technical center. These showed that with the high-tech metal detector INTUITY in combination with the THiNK software, the requirements of Loidl could be met with sensitivity sizes of Fe 1.0 to 1.3 mm, Non-Fe 1.0 to 1.3 mm, and VA 1.3 to 1.8 mm. Loidl received a UNICON metal detection system consisting of an INTUITY metal detector, conveyor belt, control unit with THiNK software, and pusher rejection system.

.jpg)

The customer benefit: Highest product quality for the end customer.

With the INTUITY solution with THiNK, salamis that have a high product effect can be examined more efficiently and better. The required sensitivity to aluminum and iron is reliably achieved. Sesotec was able to conduct a field test with INTUITY and THiNK in production at Loidl and gained valuable insights. The THiNK software was perfectly adapted to the requirements of Loidl. Johannes Vogel, Head of Sales Meat Products Corporate Group / Plant Manager St. Stefan im Rosental, is enthusiastic about the Sesotec solution: “INTUITY with THiNK is ‘awesome’, everything worked great and runs without problems. The slicers are protected from damage by metal particles, and it is a very good feeling to have the latest and best technology in use. For our end customer, the highest possible product quality is guaranteed. Sesotec took care of Loidl's concerns and actively and promptly developed a solution. We will definitely turn to Sesotec again when another metal detection project arises.”

Download this case study as a document.