Compendium of Foreign Body Detection - PART 1

Why are industrial metal detectors used in food production?

Metal detectors for food are mainly used to protect consumers. Despite the greatest care, contamination of food with metallic impurities during production cannot be completely ruled out. Metal parts that enter the product during production or are already present in the raw material can lead to significant injuries to the consumer. The consequences for the affected companies are as varied as they are serious. Claims for damages and expensive recalls place an immediate and heavy burden on the company. However, even greater and, above all, longer-lasting damage is caused by the loss of image or trust that is triggered by impure food.

Metal detectors for food effectively protect against ferrous and non-ferrous metals (aluminum, stainless steel, etc.). They can be used at any stage of the production process and for many different applications, such as the inspection of bread and baked goods, meat and sausage, fruits, vegetables, dairy products, spices, sugar, and much more.

In addition to consumer protection, metal detectors also serve to protect machinery. Even the smallest metal parts can lead to a machine shutdown. In addition to the usually high repair costs, there are costly production downtimes, which are directly associated with revenue losses.

Where in the food production process are metal detectors used?

If the metal detector is used for machine protection, it is installed directly in front of the machine to be protected. However, if consumer protection is the priority, as is the case in most instances in the food industry, multiple inspections are advisable. Inspecting the raw materials offers the advantage of removing metal parts before they are possibly reduced to a size that is difficult to detect during the production process. Examination during production at critical control points (HACCP's) is recommended to detect machine damage (e.g., knife breakage) in a timely manner.

Consequently, food products in their finished state, i.e., after packaging, are examined again with a metal detector (or also with an X-ray device) to reliably exclude contamination.

To ensure optimal protection of the product, it is advisable to inspect raw materials, individual critical control points, and conduct a final examination of the finished product.

How do metal detectors work?

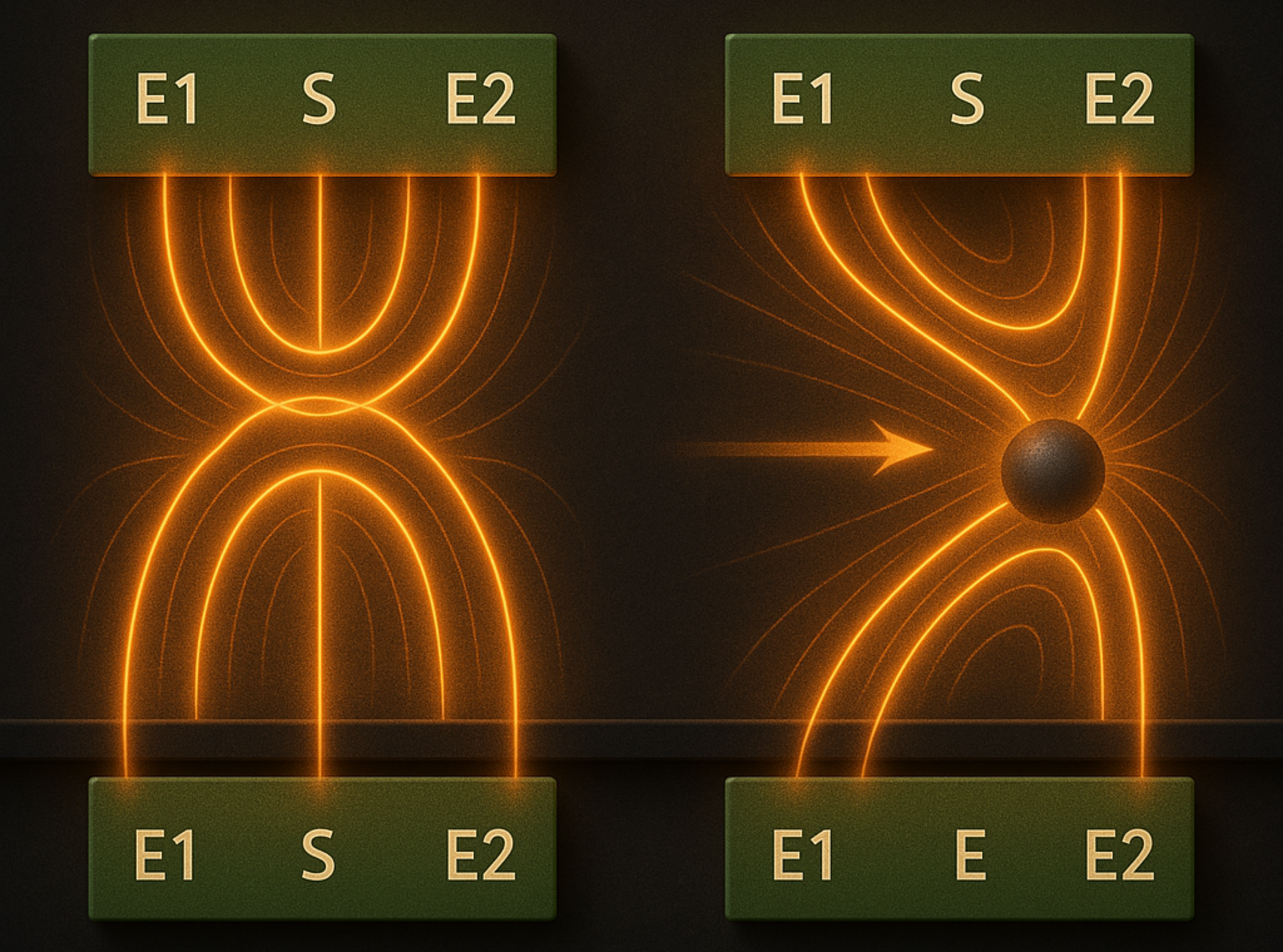

In general, there are several types of metal detectors based on different detection methods. In the food industry, metal detectors that operate on the transmitter-receiver principle are typically used (see figure). These metal detectors are equipped with a transmitter coil and two receiver coils. The transmitter coil generates a continuous electromagnetic alternating field. As soon as a metal part passes through the detector, it causes a disturbance in the alternating field, which is detected by the receiver coils. The electronics process this signal, evaluate it, and report a metal contamination.

Detection systems in the food industry are usually additionally equipped with automatic rejection mechanisms that directly remove the contaminated product from the production line.

Explore the four parts of our compendium.

PART 2

X-ray Inspection Systems for Food

Learn how X-ray detectors identify organic and inorganic contaminants in food products.

PART 3

HACCP in the Food Industry

This chapter explains at which points in the production cycle quality assurance measures should be implemented.

PART 4

Testing Contaminant Detectors According to BRC Standards

This guide explains how and when to test the performance of your inspection technology.