Founded in 1890, Josef Manner & Comp. AG is the number 1 specialist for wafers, dragees, and foam products in the Austrian wafer market. In 2019, the Austrian traditional company achieved a record turnover of EUR 222.1 million. The headquarters is located in Vienna, and production takes place exclusively in Austria. In addition to the famous Manner Neapolitan wafers with hazelnut cream, the Manner family also includes brands such as Casali with the popular rum-coconut balls and chocolate bananas, Napoli with the classic Dragee Keksi, as well as the popular Mozartkugeln from Victor Schmidt and Ildefonso. Manner products are distributed worldwide in about 50 countries, with their own sales offices active in Germany, the Czech Republic, and Slovenia.

Quality has been one of the cornerstones of the company since its founding to the present day. The highest value is placed on selected and high-quality ingredients. All raw materials undergo a thorough inspection in the quality assurance laboratories upon delivery before they are approved for production.

The quality of the food is also monitored during ongoing production, and the continuous improvement of quality standards is one of the fundamental pillars of the company's success. Since 2005, the company has been certified according to the particularly stringent food standard "IFS" (International Food Standard). This standard requires high safety and hygiene regulations and is regularly reviewed by external auditors.

X-ray inspection systems make an important contribution to successful IFS certification.

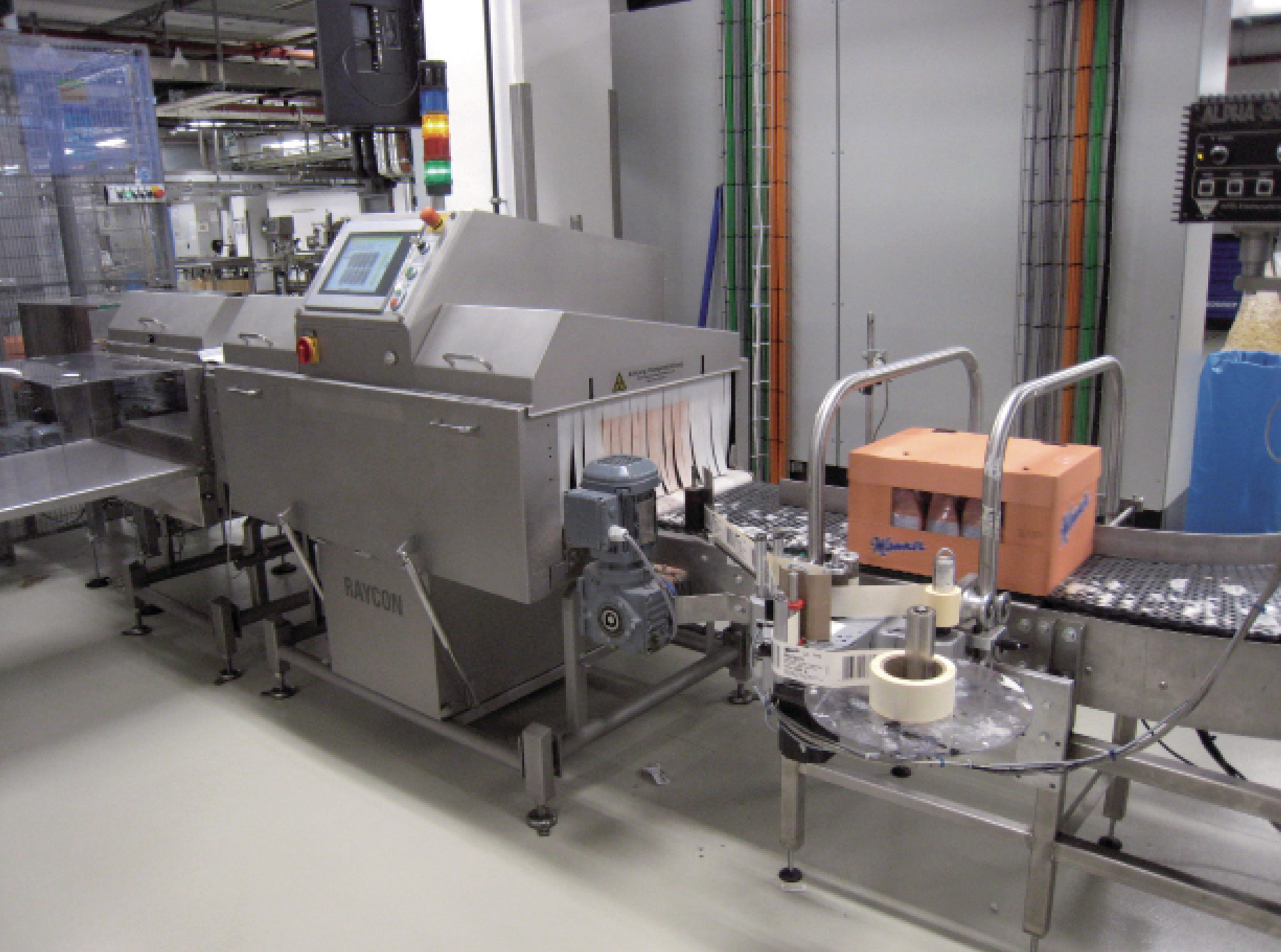

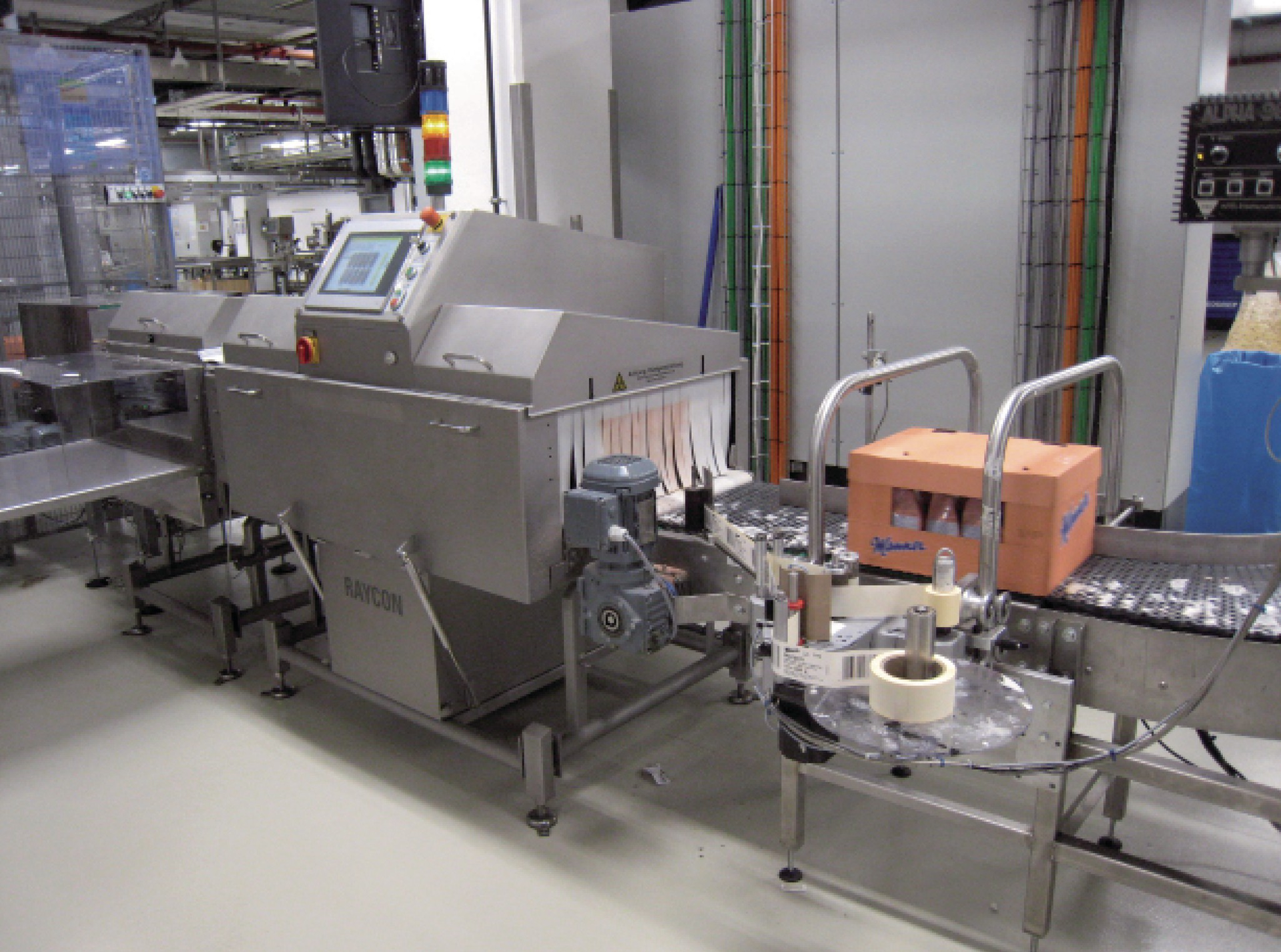

The IFS rating system stipulates that a gap identified in foreign body detection during auditing results in a point deduction that no longer allows certification at either the basic or higher level. This significantly increases the importance of foreign body detection. As one of the leading manufacturers of industrial product inspection technology, Sesotec GmbH from Schönberg supplied three RAYCON type X-ray inspection systems for IFS-compliant examination of the wafer products. Success of the measures: When the certificate was renewed in 2019, MANNER was able to achieve the maximum standard for its two production sites once again.

X-ray scanners also detect incomplete products.

In addition to the certification requirements regarding foreign body detection, there was another reason why the Austrian company was looking for a product inspection device with X-ray technology: at irregular intervals, there were consumer complaints because slices were missing in the packages. An active search was conducted for a solution to identify packages containing too few or defective wafers. These packages should be removed from the product stream before they could reach the consumer.

After extensive research with suppliers of X-ray systems, it was decided to install RAYCON product inspection systems from Sesotec for the final inspection of the packaged wafers to meet the quality requirements.

Because X-ray scanners inspect products in three ways: for foreign bodies, fill quantity, and appearance. Sensors, scales, or camera systems could not fulfill the tasks 100 percent.

Best detection accuracy with metallized packaging and high throughput.

For the examination of waffle products packaged in metallized foil, a RAYCON EX1 device with a detection accuracy of 0.8 millimeters stainless steel was used.

The bars in larger packages or in cartons are examined by two RAYCON D with the respective appropriate passage size. They have a detection accuracy of at least 1.5 millimeters. With the help of X-ray technology, not only metallic foreign bodies are detected, but also non-metallic ones, such as glass or hard plastic. To automatically eject the contaminated or incomplete products, the two RAYCON D devices are standardly equipped with pushers. For the RAYCON EX1, an air nozzle was installed for the ejection of the small 75-gram packages.

The product inspection system RAYCON guarantees optimal image processing at a high throughput speed of up to 200 product units per minute. It operates with a very low X-ray power of only 50 KV, is approved as a testing device for food and food components according to EU Directive 1999/2/EC, and requires no special precautions during installation.

Price-performance ratio of Sesotec devices convinces

The project managers Markus Purth and Ing. Christian Fichtinger are very satisfied with the Sesotec X-ray scanners: "We are constantly striving to more than just meet the requirements of quality management systems. Our products are scanned by the X-ray inspection systems, with packages containing contaminants or missing slices being ejected. Since the RAYCON devices from Sesotec have been in use, consumer complaints about missing slices have demonstrably decreased. All in all, Sesotec offers the best price-performance ratio with the lowest operating and maintenance costs, such as for a lamp replacement."

Download this case study as a document.