In 2025, the plastic recycling industry faces significant challenges and a profound transformation. Once a strategic cornerstone of the circular economy and a beacon of hope for sustainable change, it is now navigating a phase of realignment.

Global supply chains, fluctuating raw material prices, political frameworks, and a shifting market for recyclates present the industry with complex tasks. These developments demand new strategies, partnerships, and innovation to advance the goals of the circular economy. In this article, we explore the current landscape and highlight pathways to a stable and sustainable future.

The Situation in Europe 2025

The recycling industry is under immense pressure due to cheap imports and the plummeting prices of new plastic, leading to a sharp decline in recycled material prices. While "Virgin Plastic" from fossil fuels continues to be subsidized and remains cost-effective, European recyclates face higher production costs and stricter regulations.

Plastics Recyclers Europe warns: "The European plastic recycling industry is facing imminent collapse".

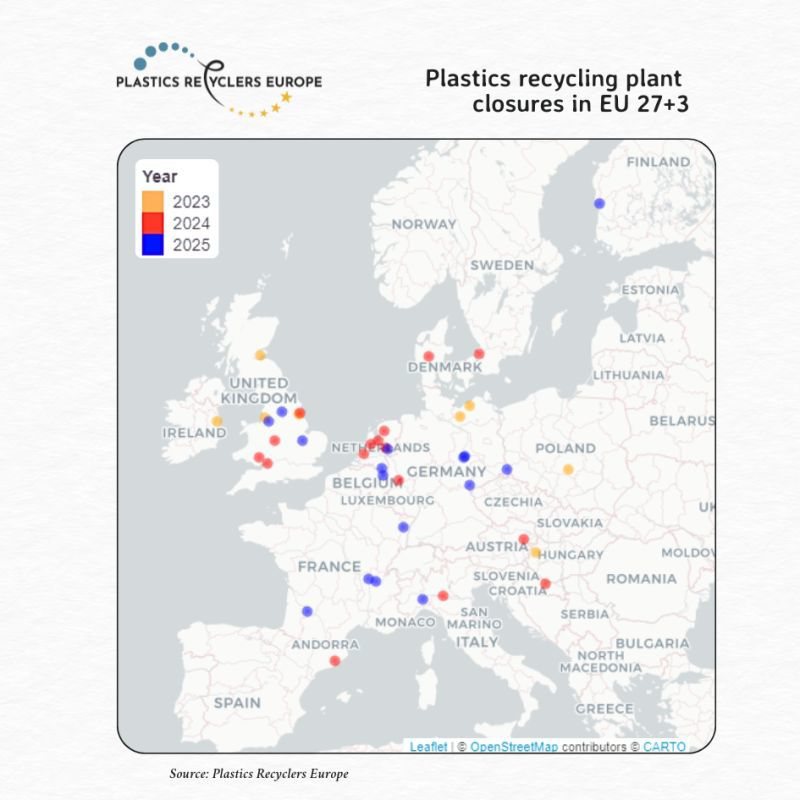

The impact is already evident: Between January and July 2025, Europe lost nearly as much recycling capacity as in the entire year of 2024. If this trend continues, three times as many facilities could close by the end of the year compared to 2023, resulting in a total loss of nearly one million tons of recycling capacity since 2023.

The most affected countries are the Netherlands, Germany, and the United Kingdom—traditionally strong recycling hubs. There is no end in sight for this downward trend. Forecasts indicate zero growth for the industry—a dramatic setback after years of dynamic expansion.

What Needs to Happen Now

The crisis must not become the new normal. Politics, business, and society must unite in action.

In response to the crisis, Plastics Recyclers Europe (PRE), in collaboration with national and European organizations such as bvse, PET core Europe, and Plastics Europe, has released a position paper outlining six strategic action areas for immediate measures essential to securing the stability of the European plastic recycling industry. (Strategic Recommendations for a Resilient and Circular Plastic Value Chain in Europe; https://www.plasticsrecyclers.eu/publications/)

1. Strengthen Trade and Market Protection

- Implement dedicated customs codes and rigorous import controls for recyclates

- Enforce monitoring and consistent penalties for non-compliance with recyclate quotas

- Impose fair tariffs on non-compliant countries to safeguard the EU circular economy

2. Reduce Energy Costs

- Ensure access to affordable, clean energy for recyclers

- Utilize member states' energy tax leeway

- Alleviate the recycling sector with subsidies and tax breaks

3. Ease Raw Material Price Pressure

- Only certified recyclers should purchase sorted waste

- Maintain material quality despite rising recycling rates

- Introduce uniform standards for sorting and reporting

4. Ensure High Quality Standards

- Implement strict quality controls for recyclates (EU and imports)

- Establish a unified EU framework for collection, sorting, and recycling

- Build trust in European recyclates

5. Simplify Regulation

- Harmonize reporting obligations EU-wide and reduce bureaucracy

- Accelerate approvals for recycling facilities (max. 6 months)

- Standardize EU penalties for recycling violations

6. Create Financial Incentives

- Offer tax benefits for products with EU recyclates in public procurement

- Establish uniform EPR systems across all member states

- Direct funding specifically to plastic recyclers

Plastics remain essential – but sustainable

Even the association Plastics Europe emphasizes:

“Plastics are indispensable in many sectors – such as healthcare, renewable energy, food supply, and mobility.”

However, sustainable use is only achievable through an effective circular economy. The association calls for country-specific recycling targets, improved access to waste infrastructure (especially in countries with inadequate collection systems), and science-based decision-making tools to identify particularly harmful plastic applications.

Through the initiative “Ring the Bell for Recycling – Support European Recyclers for a Circular Future”, which will be showcased at the K-Messe 2025, Searious Business, in collaboration with various industry players including Sesotec, warns of the impending collapse of the European recycling industry. Despite billions in investments, many facilities remain idle because cheap virgin plastic and imports distort the market, leaving demand for recyclates too low. Without mandatory quotas for recycled content, a viable business model is lacking – “no demand = no recycling.” The initiative urgently calls for fair conditions and bold political decisions to secure the future of a functioning circular economy in Europe.

Smart Sorting Technology – The Key to Sustainable Success in Plastic Recycling

Only when plastics are sorted by color and type can high-quality recyclate be produced that meets the stringent quality demands of manufacturers and processors. Pure materials mean less waste, more stable processes, and a true market advantage. At the same time, recycling not only conserves resources but also saves energy and reduces CO₂ emissions—each ton of recycled plastic prevents between 1.45 and 3.22 tons of climate-relevant greenhouse gases.

With innovative technologies, recyclers today can operate with the highest purity, efficiency, and flexibility. This includes material analysis systems for rapid quality control, compact sorting solutions for separating various materials—such as metal or plastic—by color or shape, as well as mobile sorting platforms for pure-grade plastic granulate. High-performance flake sorters for sorting plastic flakes also contribute to making recycling not only more sustainable but also economically viable.

The latest artificial intelligence technologies enable better detection and differentiation, leading to higher purity results and increased profits.

Modern sorting and analysis systems help precisely separate plastics by type, color, or shape, ensuring consistently high quality. This lays the foundation for economically viable processes that combine sustainability and profitability, strengthening the circular economy in the long term.

Conclusion

The 2025 crisis in the plastic recycling industry is a wake-up call—not just for one sector, but for our entire economy and environment. If we don't take decisive action now, we risk missing critical climate targets and the opportunity for a true circular economy. It requires political will and economic courage to revive this cycle before it breaks for good.

Advanced sorting and analysis systems can help make material flows more efficient and of higher quality. They enhance the profitability of recycling processes and lay the foundation for restoring trust in the recycled materials market.