The quality and purity of plastic materials are crucial for sustainable and cost-effective production. To ensure these standards, modern material management systems are employed.

The primary goal of sustainable plastic production and processing is to reintegrate recyclates and regrind into the plastic cycle. However, the varying quality levels of incoming materials pose a significant challenge for production. A precise analysis of the material—both during incoming goods inspection and for quality assurance at dispatch—enhances the predictability of production processes and boosts efficiency. Additionally, a mobile, automated pre-processing system can elevate low-grade recyclate to the required quality level, thereby creating an economic advantage.

Material Analysis: Fast, Precise, and Efficient Quality Control

Companies that produce new granules from recycled materials use material analysis systems for incoming goods inspection. In the recycling process, these systems are employed in quality labs to verify material purity before dispatch. Traditionally, such analyses were conducted manually—a time-consuming process with often non-reproducible results.

Modern material analysis systems, however, provide detailed reports on plastic composition and color distribution within minutes. These systems deliver reliable, standardized results with consistently high quality, thereby enhancing efficiency in plastic processing.

Challenges in Material Analysis

Quality assurance in plastics processing often relies on labor-intensive manual sampling analyses. These methods are not only time-consuming and costly but also frequently unrepresentative. Companies incorporating recyclates into their production processes face the challenge of accurately determining material composition. This is where innovative material management systems come into play, offering automated and precise analysis.

Precise Analysis Technologies for Plastic Flakes and Regrind.

Quality control of recycled plastics has traditionally relied on manual, visual, or thermal testing methods. However, these approaches are time-consuming, costly, and often provide limited insights.

Modern analysis systems offer an efficient alternative: within minutes, they can accurately identify plastic types, colors, and metal contaminants. This ensures reliable material quality, enhances process safety, and boosts the profitability of plastic processing.

Various sensor types are employed:

- Color sensors for detecting color components and off-colors

- Near-infrared sensors (NIR) for determining plastic types

- Metal sensors for identifying metallic contaminants

These automated systems enable rapid analysis and deliver precise, reproducible results. Eliminating manual analyses not only reduces labor but also improves quality assurance in production.

Advantages of modern analysis systems:

- Efficiency: Faster analysis of samples for plastic types, colors, and metal foreign bodies

- Precision: Automated and reproducible analysis using innovative sensor technology

- Profitability: Reducing manual and time-consuming testing methods for better decision-making on the usability of recyclates

By employing advanced sensors – including color, near-infrared, and metal sensors – even the smallest contaminants can be detected. The collected data is automatically compiled into reports and archived, ensuring comprehensive quality control.

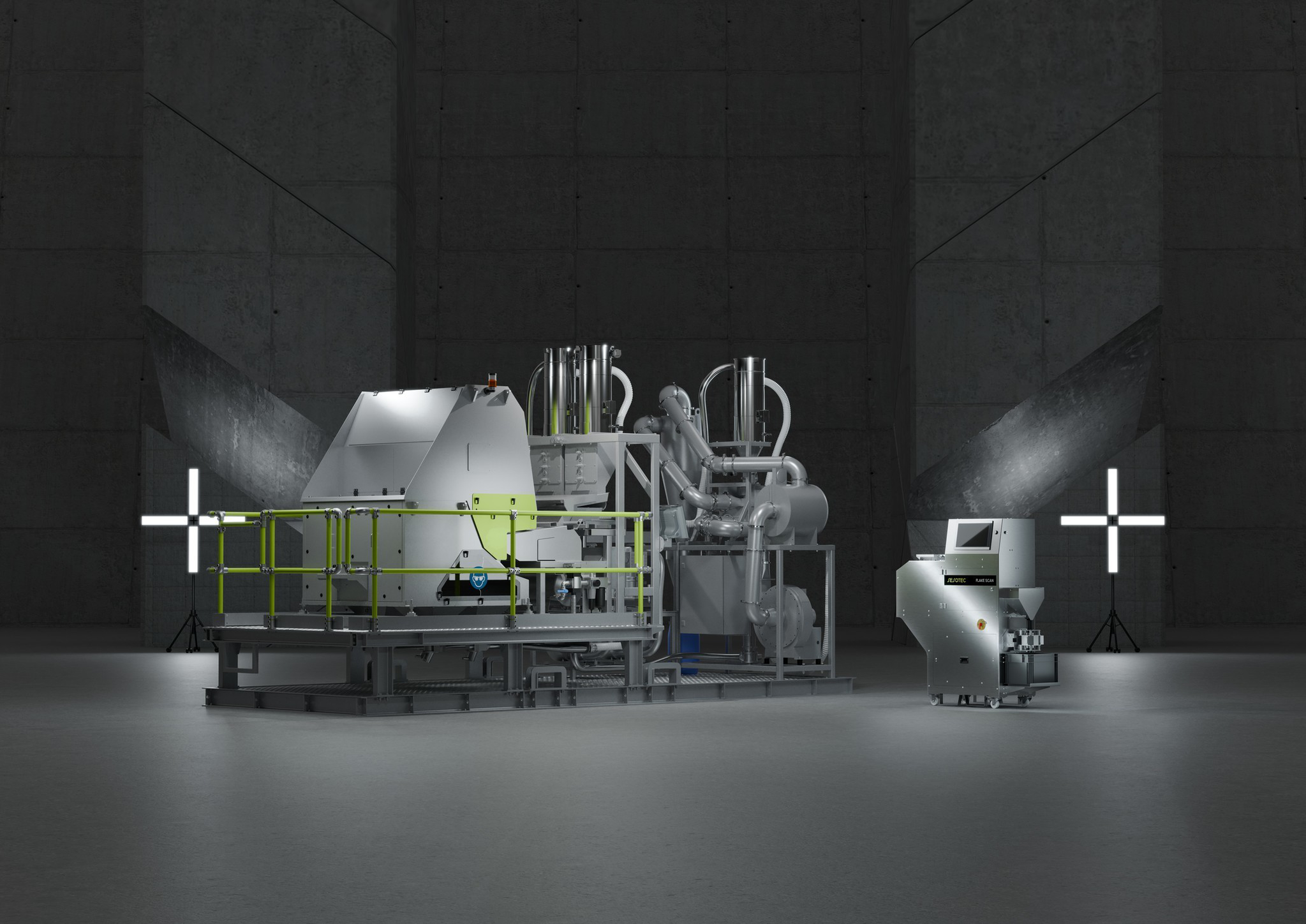

Material Processing: Comprehensive High-End Systems for Regrind Sorting.

It's not just plastic manufacturers facing the challenges of rising raw material costs, supply chain disruptions, and potential production halts due to equipment damage. Plastic processors are also grappling with these issues.

By utilizing advanced processing systems, companies can ensure stable production processes, reliable supply chains, and consistently high material quality—without relying on new materials. This approach enables economical and resource-efficient production.

Challenges in Material Processing

An essential aspect of material management is the efficient sorting of plastic materials.

The plastics processing industry faces growing challenges:

- Rising raw material prices are driving up production costs.

- Declining material quality makes consistent high-level processing difficult.

- Increasing contamination heightens the effort required for quality assurance.

Targeted pre-sorting of materials is therefore crucial to ensure high-quality, pure-grade materials and enhance production efficiency.

Automated Sorting Solutions for Ultimate Purity

In industrial plastic processing, precise sorting is as crucial as material analysis. Modern, mobile sorting systems enable efficient separation of materials by type, color, and metal content. This not only enhances process reliability but also protects downstream machinery from damage caused by foreign bodies.

Thanks to their modular design, innovative sorting systems can be seamlessly integrated into existing production lines. By combining various sensor technologies, they offer maximum adaptability to different material compositions and sorting requirements. With these advanced solutions, companies can make their production more efficient, sustainable, and cost-effective.

Advantages of modern sorting platforms:

- High flexibility through the combination of different sensor technologies

- Increased efficiency through automated sorting processes

- Reduction of contaminants for improved material quality

- Mobility through compact design and flexible use at various locations

By employing intelligent sensors and state-of-the-art signal evaluation technologies, materials can be precisely identified and contaminated components selectively sorted out. This not only improves material quality but also protects subsequent processing equipment from damage caused by foreign bodies.

Sustainability and Cost-Effectiveness through Optimized Material Management

Efficient material management with innovative analysis and sorting solutions is crucial for enhancing resource efficiency in plastics processing.

With precise material analysis and optimized material preparation, you can:

- Reduce contaminants

- Minimize material loss

- Enhance product quality

Companies benefit from a more sustainable and cost-effective use of recycled plastics, securing a competitive edge. Modern material management systems are thus essential for resource-efficient and future-oriented production processes in the plastics industry.