Setting New Standards in Metal Detection, X-ray Inspection, Software, and AI

At FACHPACK from September 23 to 25, 2025, in Nuremberg, Sesotec demonstrates how Artificial Intelligence, Compliance, and the continuous evolution of its product portfolio ensure maximum food safety. Under the motto "Food Safety is our Passion: Anytime and anywhere." visitors at the Sesotec booth 3C-305 in Hall 3C will discover how intelligent inspection systems and smart software solutions detect even the smallest foreign bodies, ensure compliance with international standards, and optimize processes across entire food production lines.

Next-Level Innovation: Highlight Topics and World Premiere

Artificial Intelligence (AI) with real added value, the software features of the Compliance Package, and the new INSIGHT.HMI interface accompany the launch of two world-firsts in metal detection: the new high-end metal detector INTUITY NEX with an optional new hygienic conveyor belt concept from the VARICON+ series.

Two Innovations in One: AI-Powered THiNK Technologies with the New RAYCON D+ TX

The RAYCON D+ TX X-ray inspection system, launching at IFFA in May 2025, is the latest addition to the RAYCON family, setting new standards in detection accuracy with its advanced high-resolution TDI line detector.

The Benefits:

- Significantly enhanced image quality, higher contrast, reduced noise, and more precise detection of even the smallest foreign bodies.

- At the same time, the high-end model features integrated AI-based THiNK Technologies. Thanks to the perfect synergy of innovative hardware and artificial

- intelligence, the system achieves unprecedented detection performance, especially on fast production lines.

Always Secure, Always Compliant – with the Sesotec Compliance Package

Food safety allows no compromises. True to its trade show motto, Sesotec focuses on solutions centered around users and customers. The Compliance Package software ensures guideline-compliant production in the food industry with seamless and efficient documentation—minimizing manual effort to the bare minimum.

The software package consists of five components, some patented by Sesotec:

- Audit-Check (Process assistant for audit routines including logging)

- Sensitivity Prediction (Automatic determination of detection sensitivity for various foreign bodies after learning process or significant setting changes)

- Compliance Mode (Audit standards at the push of a button with reduced false reject rate)

- Integrated Compliance Monitoring (ICM: Continuous self-monitoring of the inspection system's detection capability)

- Integrated Validation Process (IVP: Sesotec certificate with validation results as proof of quality goal compliance)

Combat the Skills Shortage: Simplify Device Operation with INSIGHT.HMI

Insight.HMI is user-centric control software that enhances every production line from the very first setup—making it more efficient, effective, and ultimately safer. With operators in mind, control is managed through widget modules that provide all essential information at a glance, soon to be paired with intuitive shortcuts for additional settings. Graphical displays enable quick and intuitive understanding of device and production performance. The generous seven-inch screen size of the VARICON+ GLS MF metal detector offers a clear, modern interface that adheres to the latest web standards, featuring structured layouts, contemporary screen design, and enhanced graphics. Its premium surface ensures reliable device cleaning and signal reception in any production environment. Settings and analyses are no longer confined to the device on the line: when the Control Unit and a mobile device are on the same network, a QR code scan on the device can mirror the display 100% on the mobile device.

World Premiere: New High-End Tunnel Metal Detector INTUITY NEX

The new INTUITY NEX represents a groundbreaking coil design for tunnel metal detectors with an optimized housing construction that meets the highest hygiene requirements and complies with protection class IP 66/69K.

Combined with the new capacitive touchscreen and the intuitive Insight.HMI interface, it results in a particularly user-friendly, future-oriented system – featuring gesture control and remote visualization. The new Multi-Simultaneous Quattro Frequency Technology, with four search frequencies operating in parallel, together with the advanced AI-based THiNK Technology, ensures even greater detection accuracy. When it comes to line integration, the INTUITY NEX also promises maximum flexibility – easily and quickly via interfaces such as OPC-UA, MQTT, or REST-API.

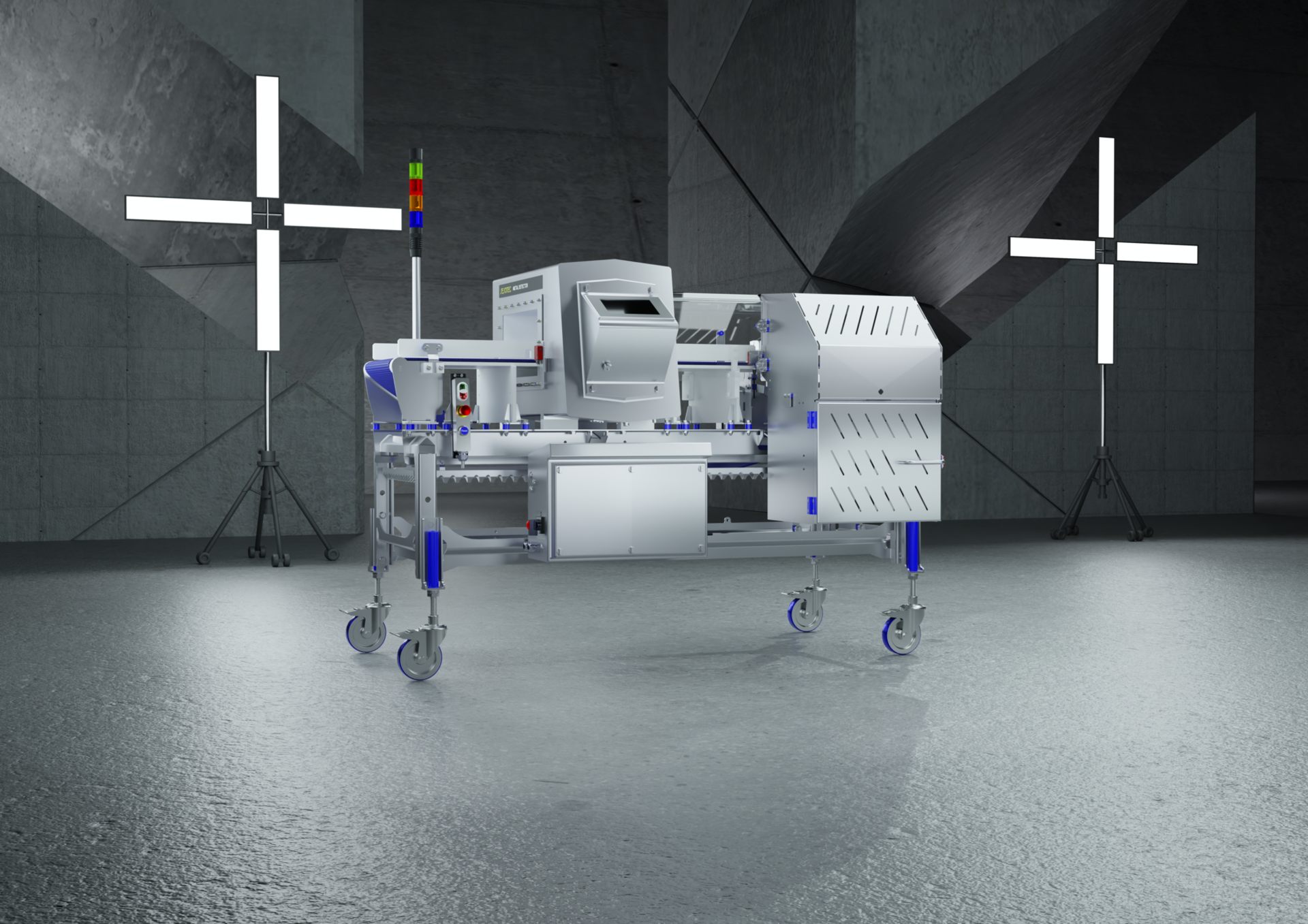

For the most demanding production environments: Introducing the new hygienic conveyor belt concept of the VARICON+ series

Introducing Sesotec's cutting-edge conveyor belt concept, perfectly aligned with the latest detection systems and designed specifically for hygiene-sensitive applications. This modular design eliminates hollow profiles, ensuring rapid, tool-free cleaning and maximum hygiene safety. It features options like the IP66/69K protection package for wash-down applications and a tool-free removable cover with a cleaning mode. Smooth, streamlined surfaces, tool-free removable guide rails, and an OSHA-compliant PET-G protective cover guarantee top-notch safety for both workers and products. With adjustable height (790–960 mm), the convenient Sani-Clip system for quick belt changes, and a compact design, the new VARICON+ series conveyors integrate seamlessly and swiftly into both existing and new production lines.

Ultimate Safety for Free Fall: RAPID 5000 Metal Separator with Inline Test Function XS

The RAPID 5000 metal separator, paired with the manual Inline Test Device Freefall XS, revolutionizes testing in the food industry by streamlining the functionality checks of metal separators installed in free-fall pipelines.

This testing device enables IFS-compliant tests right at the heart of your product flow. Special configurations are available for ATEX environments, ensuring adherence to all relevant safety regulations. Together with the automatic testing feature, they provide food manufacturers and processors with unparalleled safety and full compliance.

Our inspection systems, tailored for every production stage and conveyor type, along with our software and service solutions, provide the food industry with the essential security needed to ensure top product quality while meeting demands such as the hygienic design of inspection systems.

Discover all exhibits, detailed information, and get your free visitor tickets on the Sesotec FACHPACK website.