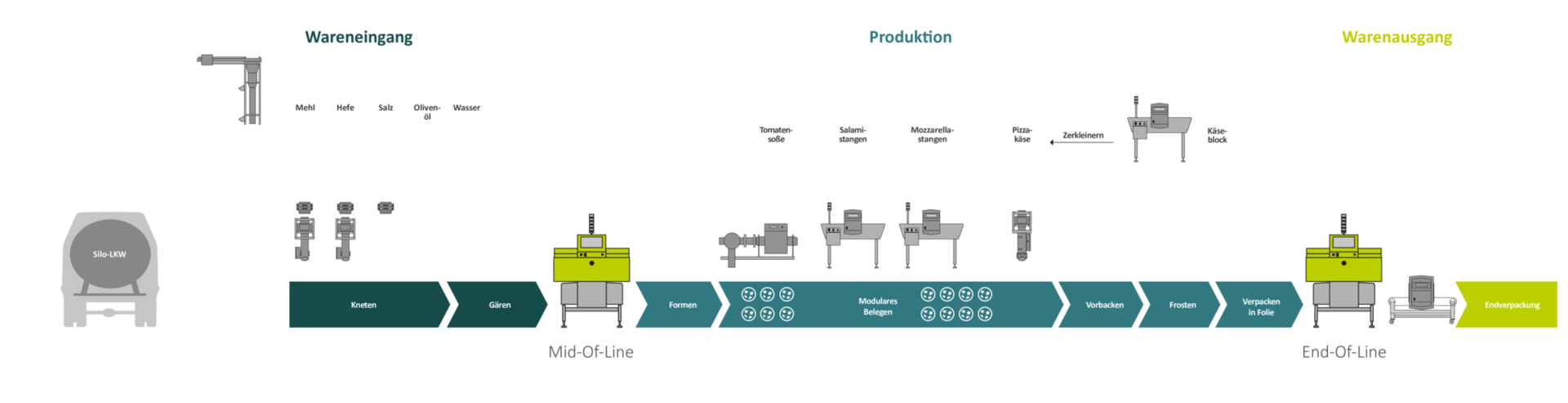

Identifying and controlling control points (CP) and especially critical control points (CCP) are important aspects of food safety. The focus is often placed on critical control points and particularly on end-of-line inspection. However, the importance of upstream controls should not be overlooked in order to ensure both product quality and profitability. In this article, we explain the differences between CPs and CCPs and discuss the importance and benefits of continuous control of the entire production line.

What is a Control Point (CP)?

CPs are specific work steps in the process chain that are regularly checked to ensure the specific properties of a food product.

They are specific points along the line (from goods receipt to goods dispatch) in a manufacturing process where control or monitoring can be carried out to ensure food safety. They are process points where there is no increased risk of hazard and can be controlled by general hygiene and quality measures. Whether and which controls are carried out at these points is generally at the discretion of the manufacturer.

An example of a CP is the raw material control at the goods receipt of a muesli manufacturer: The supplied nuts are examined with an X-ray inspection system for bulk goods to find foreign bodies (metals, stones).

What is a Critical Control Point (CCP)?

CCPs are indispensable process steps where it is possible and crucial to prevent, eliminate, or reduce a food safety hazard to an acceptable level. Critical control points are process points where actions must be taken to avoid or reduce a specific hazard/health risk.

It is important to identify critical points in the food manufacturing process so that appropriate control measures can be taken to reduce the risk of contamination. It is, so to speak, the last step in controlling, avoiding, or eliminating a contamination risk.

CCPs are only useful if they are regularly monitored. Therefore, it is not only necessary to identify these points and establish critical limits for each one, but also to collect and compile data to monitor the processes and determine when a dangerous situation occurs.

An example of a CCP is at the goods output of a cereal manufacturer: end-of-line control of the finished packages with selected foreign body detection technology (X-ray inspection systems or metal detection systems) to find foreign bodies that may have entered the product during the manufacturing process.

The importance of foreign body detection End-of-Line

The identification of control points and critical control points (CCPs) is important for ensuring food safety. The "end-of-line control point" is generally considered the most important critical control point. This is true insofar as physical contamination can usually be ruled out after this point. It is therefore crucial for the quality of the final product and the safety of the consumer.

Why is end-of-line foreign body detection not enough?

The inspection at the end of the production line is, as described above, one of the most important points when it comes to food safety and a basic requirement of food standards such as IFS. However, an exclusive focus on this neglects important factors such as cost-effectiveness/value creation, sustainability and resource conservation, as well as the traceability of contamination sources.

If foreign body detection takes place before and during the production process, it is associated with many advantages:

- Foreign bodies, such as metals, glass, bones, and much more, can be sorted out early before they are broken down into countless small splinters by mills and other crushing machines, which may then be too small to be detected later in the final inspection.

- Costly damage to subsequent grinding systems, extruders, and calender rolls, which can lead to additional contamination, is avoided.

- If contamination occurs, foreign body detection before and during the production process offers effective approaches for root cause analysis (suppliers, batches, machines, times, frequency distributions).

- If contamination in food is only detected at the goods exit (end-of-line), finished products and often the entire batch must be disposed of. The produced food is "wasted" without reason. This also applies to the packaging used. With early detection of foreign bodies, only incomplete products or individual ingredients may need to be disposed of, which makes a significant contribution to resource conservation (raw materials, processing, energy, packaging, etc.).

- Early detection of contamination can also prevent value creation losses. If finished, contaminated products have to be disposed of, many resources (time, raw materials, energy, etc.) have already been invested in the product. If foreign bodies are detected in time, these resources do not need to be used. Costs for the disposal of entire products are eliminated. This increases efficiency and profitability.

Conclusion

The examination of already packaged food with foreign body detectors is standard in foreign body control routines for food manufacturers. However, a risk analysis usually shows that contamination can be detected much earlier and efficiently avoided. Contaminations can originate from a wide variety of sources and process steps: incoming raw materials, sieve and knife fragments, damaged machines, operator carelessness, or machine wear. The proportion of sorted-out goods or packaging can be significantly reduced if the raw materials at goods receipt or the products during the production process are examined with an inspection device.

Foreign body inspection should extend throughout the entire production process, from goods receipt, through processing, to goods dispatch. Only in this way can the food industry produce safe food, avoid wasting resources, and thus ensure economic efficiency.

Experts in inspection systems like Sesotec offer innovative and highly sensitive foreign body detectors for all critical control points in the production process.