Tunacor Fishing Ltd is a leader in Namibia's fishing industry, boasting a fleet of twelve fishing vessels. Committed to quality and reliability, the company has been consistently enhancing its products for years to ensure customers receive the very best.

The Problem: Metal Clips in Fish Sausages

Tunacor Fishing Ltd produces fish sausages, which are particularly popular in Spain. However, there have been increasing complaints about customers occasionally finding metal parts in the sausages.

The fish sausages are made directly on the boats from by-products of the filleting process. Since fresh fish has a significant product effect and the sausages are also sealed with metal clips at both ends, finding a suitable metal detection solution proved challenging. None of the systems considered could meet the high sensitivity and robustness requirements set by Tunacor Fishing Ltd. For this reason, Tunacor Fishing Ltd contacted Baader Namibia, a partner of Sesotec. Baader Namibia tackled the challenging conditions and developed the optimal solution for the customer.

The Solution: Implementing a Metal Detector During Manufacturing

Upon closer examination of the process, it was revealed that customer complaints primarily arose from metal clips found in the fish sausages. These clips entered the vacuum filler and then the sausages from two sources:

- Clips lying loose on board

- Clips from burst fish sausages returned to production

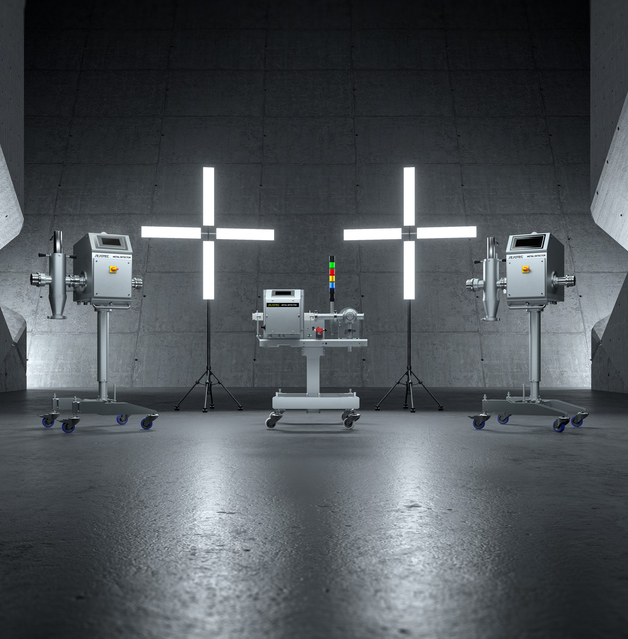

Therefore, it made sense to integrate metal detection directly at the critical process step at the vacuum filler. An end-of-line solution was ruled out. For the needs of Tunacor Fishing Ltd, the LIQUISCAN VF+ metal detector is the optimal solution, as it can be perfectly aligned with the vacuum filler and clipper.

The LIQUISCAN VF+ pipeline metal separator is designed for monitoring viscous masses, such as sausage meat. When metal is detected, the filling process is either stopped or the contaminated mass is automatically diverted into a container using a separation system. Various threaded adapters allow for connection to standard vacuum fillers.

The simplicity of the solution impressed Tunacor Fishing Ltd. The decision for Baader Namibia and Sesotec was made very quickly.

Customer Benefit: Say Goodbye to Complaints

In early 2020, Baader Namibia commissioned the Sesotec metal separator LIQUISCAN VF+ on board the Tunacor Fishing Ltd vessel. From the start, Tunacor Fishing Ltd was impressed not only by its user-friendly operation, high quality, and process stability but also by the detection accuracy it achieves.

Since the installation of the LIQUISCAN VF+ metal detector for filler applications, Tunacor Fishing Ltd has experienced no customer complaints about metal contamination. Tunacor Fishing Ltd is pleased with their decision to partner with Baader Namibia and Sesotec. They particularly value the professional advice, the expertise of their contact person, and the prompt on-site service.

Baader Namibia and Sesotec installed a metal separator directly in the processing facility on a fishing vessel. Since the LIQUISCAN VF+ was put into operation, there have been no customer complaints about metal clips in the fish sausages.

Download this case study as a document.

.jpg)