The use of X-ray devices in the food industry

Product inspection has become an indispensable element of responsible food production and an integral part of an HACCP concept or a prerequisite for successful IFS certification. The contamination of food with foreign bodies can lead to serious consequences for a company, as according to the Product Liability Act, every food manufacturer is liable for contamination of their product if a consumer is harmed as a result. To prevent this, devices for foreign body control are used. Metal detectors provide valuable assistance in detecting magnetic and non-magnetic metals, but they reach their limits with, for example, aluminum-coated packaging material. However, contamination from glass, ceramics, stones, etc., is also a serious problem.

How does an X-ray machine work?

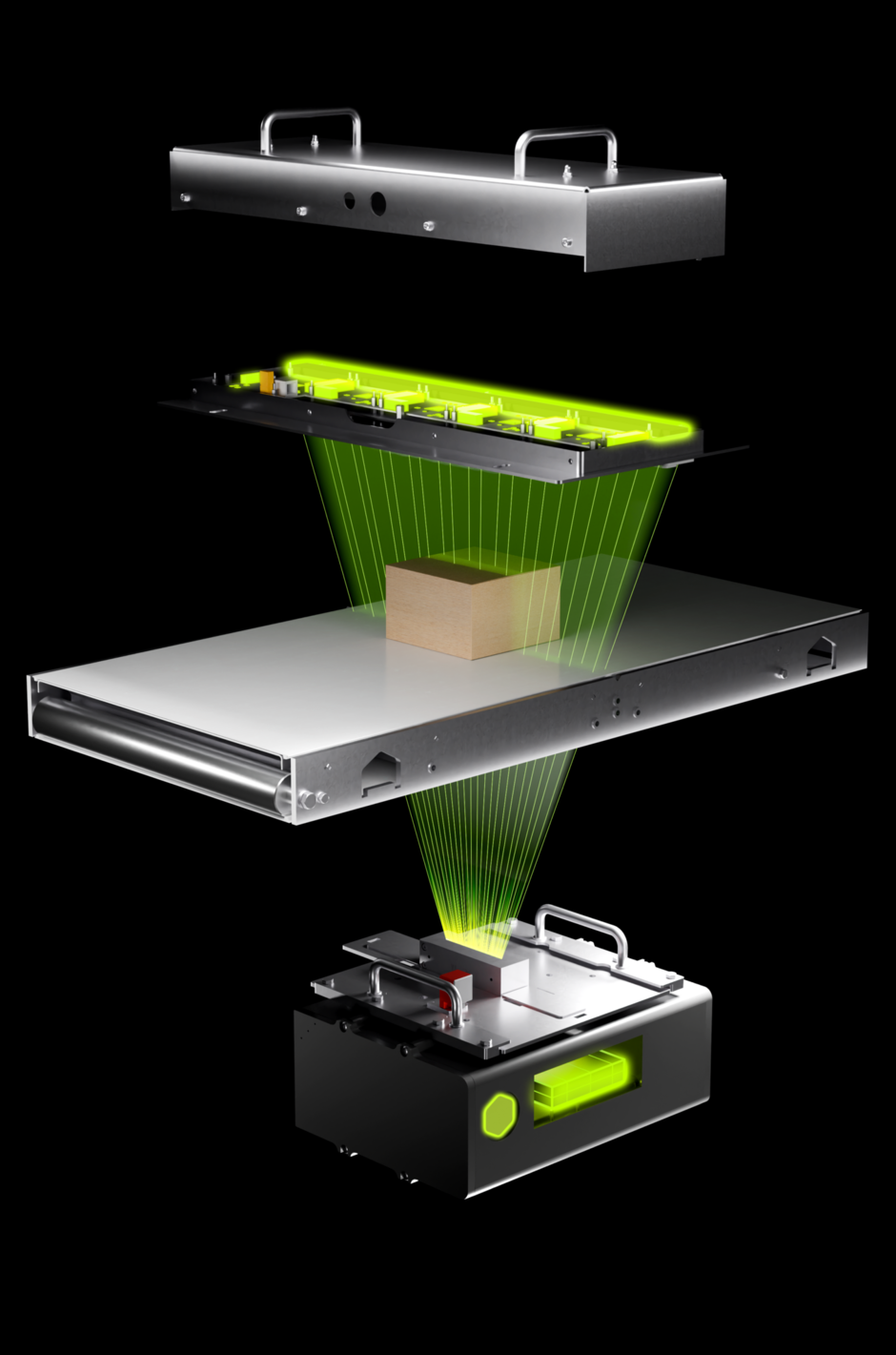

The X-ray radiation for "scanning" is generated by an electric X-ray tube. Above the conveyor belt is a line-shaped detector that measures the incoming radiation (see photo). X-rays are very high-energy and thus capable of penetrating solid objects.

Depending on the density of the examined object, the rays are attenuated more (high density) or less (low density) when passing through the product. The remaining radiation is converted into an electrical signal by the detector. This allows differences in the density of the examined object to be visually represented. The higher the density of a material, the darker it appears on the X-ray image, and vice versa. The image processing software detects the contrast differences in the image, marks the foreign bodies or missing products, and outputs a corresponding signal.

Every manufacturer or processor of food is obliged to bring only "safe" products to the market.

This is required by international and national laws. Guidelines support manufacturers in implementing these requirements.

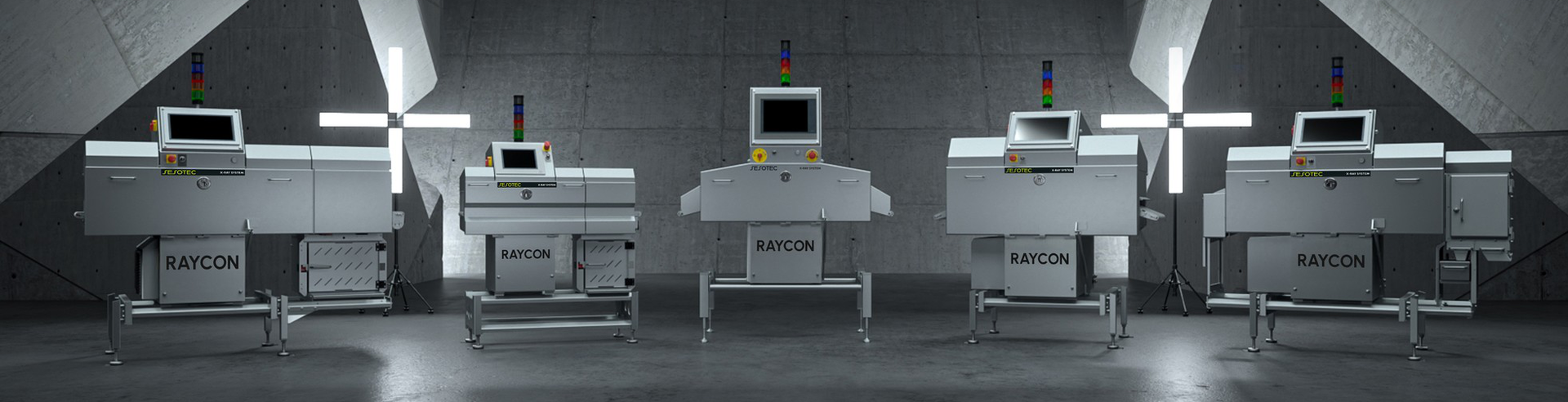

The X-ray inspection system RAYCON

Our devices meet all the requirements of common food standards, ensuring you the necessary certifications and eliminating any delivery restrictions. Because the food industry never sleeps: more and more retailers only accept goods that have been inspected with an X-ray device.

The RAYCON is a highly efficient X-ray system that detects all foreign bodies that absorb X-ray radiation better than the surrounding product due to their density, chemical composition, or mechanical dimensions — in short: foreign bodies that are denser than the actual product. Our "Dual Energy Technology" is already in the starting blocks to free your product even more effectively from poorly conductive foreign bodies, such as bones, ceramics, and plastic, in the future.

RAYCON in the test

Defects

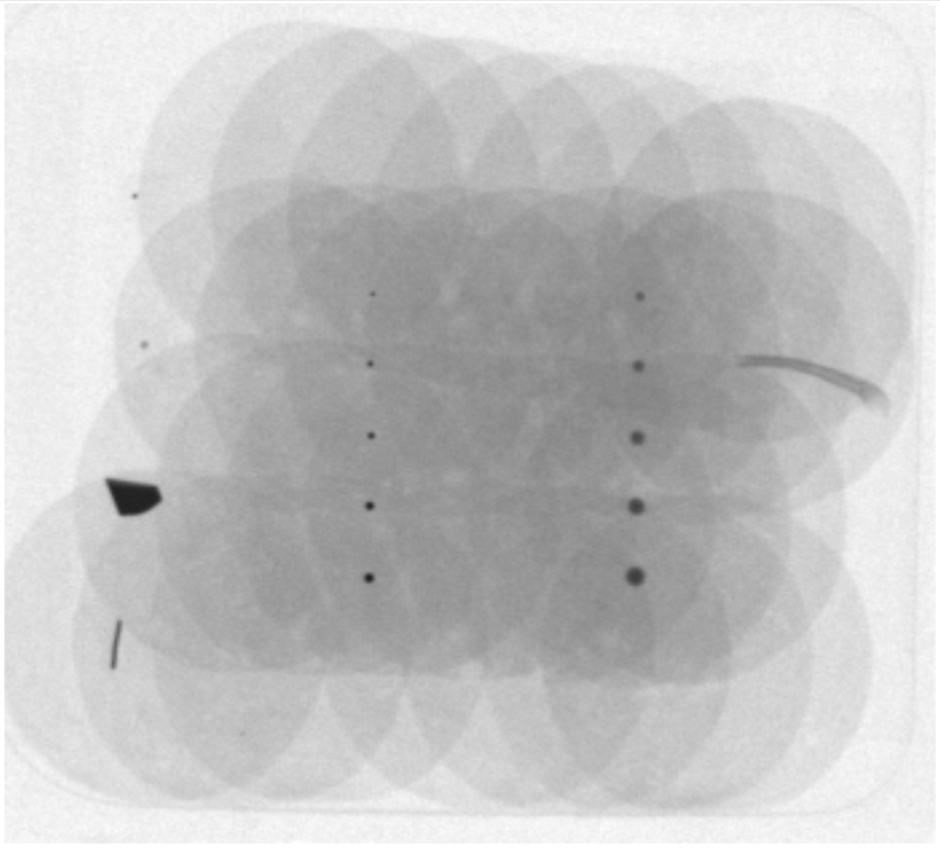

RAYCON specializes in small and medium-sized packaged products. The performance of RAYCON was tested for the detection of glass, stainless steel, ceramics, Teflon, and bone fragments using test cards in various products.

Technology

With the product inspection system RAYCON, all foreign bodies can be detected that absorb X-rays better or worse than the surrounding product due to their density, chemical composition, or mechanical dimensions. For the tests with RAYCON, a detection performance of 50 kV was applied. For small packaged products, the device achieves an inspection performance of 150 - 200 pieces per minute.

Results

The test cards with stainless steel, glass, ceramic, and Teflon are detected by RAYCON with 100% detection accuracy. Bone parts can also be safely detected in flat products.