On the way to a functioning circular economy, it is the declared goal of industry, society, and politics to transform today's waste into tomorrow's secondary raw materials. With the Packaging Act and the renewed EU Waste Framework Directive, politics has already achieved initial successes, but stricter regulations and controls are needed to establish a reliable market for recyclates and further increase recycling rates. In this article, we examine the development of the recycling rate and the recyclate content and their impact on the plastics industry.

What is meant by the recycling rate?

The recycling rate refers to the proportion of valuable materials actually recycled from waste. A distinction is made between secondary components (complete, reusable components) and secondary raw materials. However, the reference figures used to calculate the recycling rate are as varied as they are controversial. This is because the recycling rate is often equated with the recovery rate. However, the latter also includes the energy recovery of valuable materials from waste – i.e., energy recovery through incineration and thus resource wastage – whereas the recycling rate excludes this type of recovery.

The Circular Economy Act defines recycling in Paragraph 3, Section 25 as "any recovery process by which waste is processed into products, materials, or substances either for the original purpose or for other purposes." Furthermore, it is stated that recycling excludes "energy recovery and processing into materials intended for use as fuel or for backfilling" (Section 23a).

According to the study Material Flow Analysis of Plastics in Germany 2019, 99.4% of the total 6.3 million tons of plastic waste in this country is recovered, but only 47% is recycled. Only 33% of plastic waste from private households is recycled. The reason for this discrepancy is that plastics in the industry are usually clean and homogeneous, whereas in households they are heavily mixed.

This is where proper waste separation by consumers comes into play, as mixed waste is difficult to recycle. The better the separation at home, the easier it is for different packaging to be sorted and subsequently recycled in the facilities.

EU Waste Framework Directive

To increase the recycling rate for municipal waste, the EU Waste Framework Directive of 2008 was further tightened in 2018. While the original directive required a recycling rate of 50% for certain materials in each country by 2020, the revised Waste Framework Directive (EU-RL 2018/851/EG) sets targets of 55% by 2025, 60% by 2030, and even 65% by 2035. The calculation of the recycling rate has also changed with the new EU requirements. Until now, EU member states have based their calculations on so-called input calculations. This means counting what enters the recycling system from a collection system. In the future, EU-wide output-oriented quotas will apply. Only waste that is actually reused is considered recycled. To ensure uniform application of the calculation rules, the EU Commission has established specific calculation and measurement points for the most common waste and recycling processes.

How has the recycling rate for plastic developed in recent years?

In 2019, 6.28 million tons of plastic waste were generated in Germany. About 85.2% of this waste was generated after use (so-called post-consumer waste). The remaining 14.8% occurred during the production and especially the processing of plastics. That sounds like a lot of recycling material. But far from it. As the Plastikatlas published by the Heinrich Böll Foundation in 2019 shows, 60% of our plastic waste is "energetically recovered". The remaining almost 40 percent is recycled.

Development of recycling of plastic packaging

According to the IK Industrievereinigung Kunststoffverpackungen e.V, a clear positive trend in the recycling rates of plastic packaging has been observed since the German Packaging Act came into force in 2019. These have, as can be seen from a study by the GVM Gesellschaft für Verpackungsmarktforschung, increased by 12.3% in 2019 in the area of private end consumption. Consequently, in 2019, plastic packaging had rates of a total of 55.2%, based on the overall market. According to the ZSVR (Central Agency Packaging Register), the very ambitious legal recycling rate of 58.5% was almost achieved.

IK Managing Director Dr. Isabell Schmidt is pleased with this development: “The rapid increase in recycling is a tremendous success of the new Packaging Act, for which our industry has advocated.”

At the same time, Schmidt emphasizes that the circular economy must now gain further momentum and that it is now a matter of strengthening the financial incentives for recyclable packaging design so that investments in new packaging designs pay off for everyone. A renewed review of the Packaging Act is planned for 2022.

What is meant by recyclates?

The term "recyclate" is primarily used in the plastics industry and is synonymous with reprocessed plastic waste. Recyclates are obtained using different reprocessing methods depending on the condition of the plastic waste to be recycled. Basically, plastic recyclates are divided into two categories: "Post Industrial Recyclates" and "Post Consumer Recyclates".

Post-Industrial Recyclates

Post-industrial recyclates are obtained from industrial waste that occurs as scrap during the production process. They are usually homogeneous and can therefore be shredded and recycled with the help of special plastic mills without much sorting and cleaning effort. Post-industrial recyclates are particularly high quality due to the clean starting material and are therefore preferred by many companies. However, there are areas of application such as food, cosmetics, and pharmaceuticals where even the homogeneous post-industrial recyclates may not be used or only used to a limited extent due to the highest requirements for product safety and hygiene.

Post-Consumer Recyclates

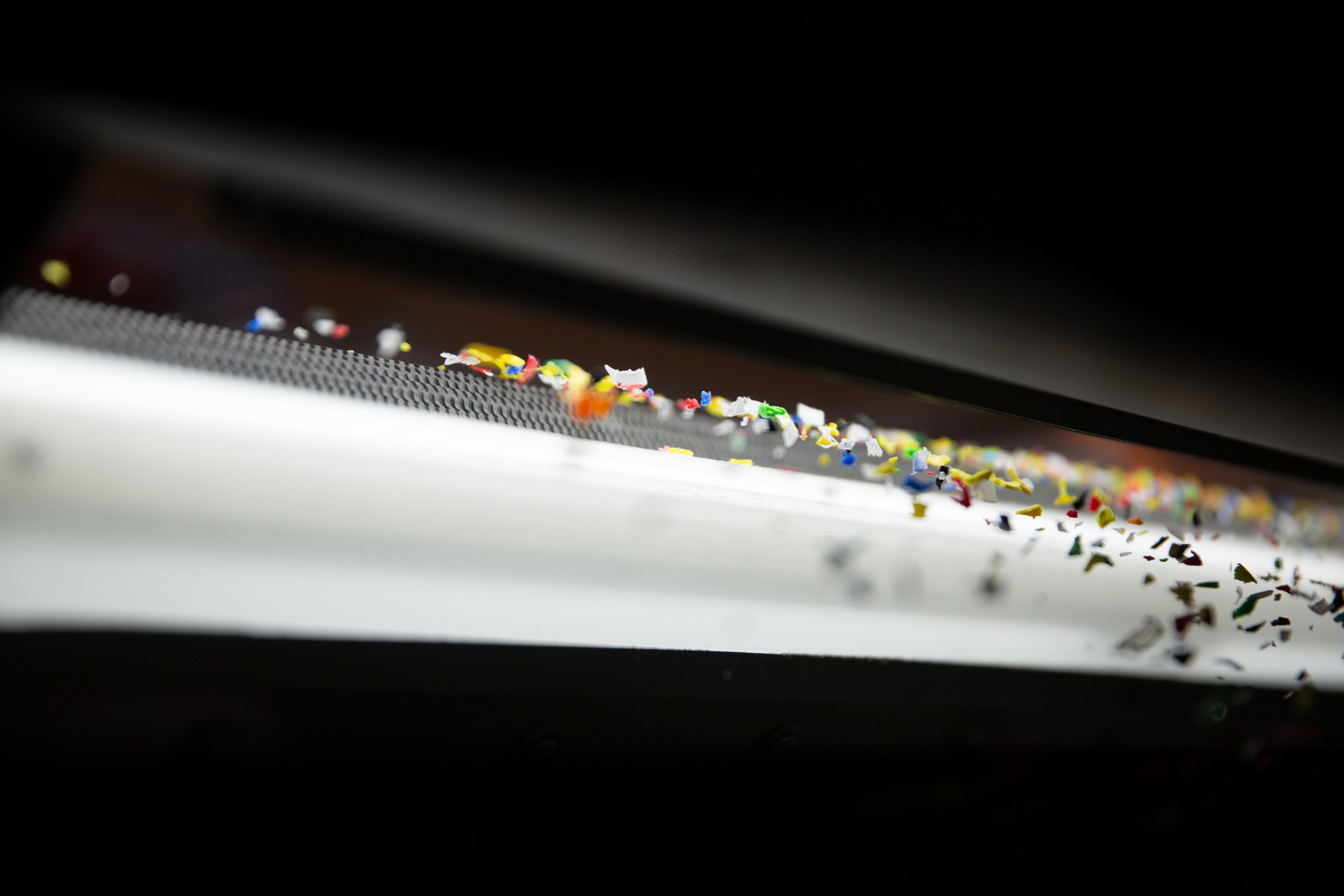

These recyclates are obtained from consumer waste, namely the yellow bag or yellow bin. Post-consumer waste is collected, sorted by type of plastic (PP, PE, PS), shredded, washed, and then melted into plastic granulate. Since packaging made from various types of plastic is mixed in the yellow bag, processing into high-quality recyclate is more demanding and requires the most modern recycling and sorting facilities.

Development of the Recycled Content and the Consequences for the Plastics Industry

Recyclates are becoming increasingly important as raw materials for new plastic products. This was also demonstrated by the 2019 publication Material Flow Analysis of Plastics in Germany. In 2019, 13.7% of the total plastic processing volume was covered by recyclates. Since the last survey in 2017, the amount of recyclates has increased by about 5% per year. However, there is still significant room for improvement in the use of recyclates.

The IK (Industrial Association for Plastic Packaging) sees the main obstacles to the use of recyclates in the lack of availability and partially inferior quality of the recyclate material. Recyclers and waste management associations have therefore been calling for political measures since mid-2020. Baden-Württemberg's Environment Minister Franz Untersteller from the Green Party advocated for a "mandatory recyclate content in plastics" at the Resource Efficiency and Circular Economy Congress in Stuttgart. The Federal Council, however, rejected the demand for national recyclate usage quotas for certain products. The reason: While plastic recyclates are already routinely used in many areas, such as construction, packaging, and agriculture, the hurdles are very high in other areas like food and cosmetic packaging, which have special requirements for the quality of recyclates. For such sensitive applications, the necessary quantities and qualities of secondary raw materials are currently not available.

The quality and safety of products must not be compromised by the use of recyclates. According to the IK, optimized waste separation by the consumer plays a crucial role, and investments in high-tech sorting and high-quality processing are needed to handle the required quantities and sort them optimally. Only through smooth cooperation among all parties involved – from consumers to recyclers to manufacturers and processors – can a stable market for recyclates be established in the long term.

Challenges for recyclers, plastic manufacturers, and processors

Due to the increasing demands on recyclate quantity and quality, not only is the pressure on recyclers to produce more pure-grade material increasing. Manufacturers and processors also need to use more recyclates to meet future customer demands and legal requirements. On the one hand, machines need to be retrofitted to process more materials, and on the other hand, state-of-the-art material analysis systems, sorting devices, and metal separators are needed to handle inferior qualities and reliably eliminate any contaminants.

Conclusion

The terms recycling rate and recycled content are often used synonymously, but they have different meanings. While the recycling rate represents the proportion of waste that is recycled, recycled content refers to the proportion of secondary raw materials that are incorporated into new products. Both the recycling rate and recycled content are important factors for a functioning circular economy.

However, the recycling rate is difficult to comprehend. Until now, everything that goes from a sorting facility into recycling has been calculated. Losses in the recycling process, such as the incineration of contaminants, have so far been included in the official rate. The recycling rate, however, directly affects the availability of secondary raw materials. The more material is recycled, the more material is available for the production of recycled content. To get the cycle going, the recycling rate and consequently the use of recycled materials in the production of new products must be significantly increased. This requires further measures from politics on the one hand and the willingness of all parties involved, whether consumers, recyclers, manufacturers, or processors, to contribute and work together on the other hand.