By ensuring that their buildings and machines comply with the guidelines for hygienic design, food manufacturers not only reduce the risk in their processes but also achieve a range of other benefits. Below, the food safety experts from Sesotec discuss the importance of hygienic design for food processing facilities in terms of regulatory approval and food safety standards.

What is Hygienic Design for food processing equipment?

Hygienic design refers to the design of all components of food processing machines to facilitate cleaning and reduce the risk of food contamination with biological, chemical, or physical hazards.

Some examples of hygienic design in food processing machines are:

- Sealing of dead spaces, such as gaps and crevices

- Ensuring that all areas in contact with food are accessible for cleaning

- Avoiding the formation of condensation

- Using materials that can be cleaned repeatedly and intensively without abrasion

- Eliminating components that can loosen, break off, and fall into the food

- Incorporating drying or draining devices for equipment that is disinfected with wet cleaning methods

Why is Hygienic Design important for food safety?

The hygienic design of food processing equipment has a significant impact on food safety.

Companies that manufacture and process food must ensure that their products are free from biological, chemical, and physical contaminants. Inadequate hygienic design can increase the risks to food safety, as it increases the likelihood that the food processing equipment itself becomes a factor for contamination.

By constructing equipment that is easy to clean and wear-resistant, without areas where product residues and moisture can accumulate, hygienic design significantly contributes to reducing contamination risks in food processing.

The role of hygienic design guidelines in food safety standards

Another compelling reason for adhering to proven hygienic design practices is the fact that their application is necessary to obtain regulatory approvals and food safety certifications.

Worldwide, regulatory authorities and certification bodies incorporate proven hygienic design procedures into their standards for the manufacture, installation, maintenance, and cleanability of food processing facilities and equipment. To comply with food safety laws or to become certified under a third-party food safety standard, food manufacturers must consistently adhere to the best practices of hygienic design.

In the European Union and the United States, there are two leading organizations whose guidelines for hygienic design determine both food safety law and international food safety standards: the European Hygienic Engineering and Design Group (EHEDG) and 3-A Sanitary Standards, Inc. (3-A SSI).

Below is an overview of how these organizations promote their guidelines for hygienic design in collaboration with certification bodies and regulatory authorities:

EHEDG in the European Union

The EHEDG is a non-governmental organization based in Europe that advocates for the promotion of hygienic design in food engineering. Its team of food safety experts and engineers has published more than 50 guidelines for the hygienic design of food processing facilities, production environments, and a wide range of food processing equipment.

In the third edition of their Hygienic Design Principles, the EHEDG describes a series of provisions intended to prevent contamination by foreign particles (Doc. 8, Chap. 4.5). These guidelines include considerations for the selection of construction materials, the use of hygiene covers over all open products and containers, and the implementation of an effective preventive maintenance program.

The EHEDG offers certification programs for both food manufacturers and suppliers of hygienic food manufacturing equipment. While official certification for food processors is voluntary, the application of EHEDG guidelines is a necessary part of complying with hygiene and food safety legal requirements as prescribed by European laws. These laws include EU No. 10/2011 and the EC Regulation 1935/2004, which regulate the types of materials and articles that may come into contact with food.

3 A SSI in the United States

3 A SSI was founded in the 1920s through collaboration between U.S. hygiene professionals, equipment manufacturers, and processors to improve the hygienic design of dairy pipe connections. Today, 3 A SSI maintains 70 different hygiene standards for a wide range of food processing equipment with a particular focus on dairy operations. The 3-A symbol is a registered mark that can be affixed to food processing equipment that meets the 3-A hygiene standards.

The 3-A guidelines for equipment manufacturers also include criteria that can help prevent contamination with foreign bodies. These criteria address topics such as material selection, equipment surface finish requirements, and the elimination of defects such as dead ends, crevices, and gaps.

Like the EHEDG, 3-A certification is voluntary. However, the 3-A standards serve as an important reference for regulatory authorities in the United States, such as the Food and Drug Administration (FDA) and the Department of Agriculture (USDA). The USDA Dairy Division, for example, has an approval process for all equipment used in dairies - and all equipment that meets the relevant 3-A standards automatically meets these requirements.

International Certification for Food Safety and Hygienic Design

The Global Food Safety Initiative (GFSI) is a leading international organization dedicated to the continuous improvement of food safety management systems worldwide. It develops benchmark requirements for food safety certification standards, such as IFS Food, SQF, BRCGS, and others.

In 2020, the GFSI published a new and more robust set of benchmark requirements for hygienic design: GFSI JI (for builders and equipment manufacturers) and GFSI JII (for users of buildings and equipment).

The criteria set out in GFSI JI and JII are not only based on the standards of the EHEDG and 3 A SSI but were also actively supported by these organizations. Therefore, all GFSI-recognized international food safety certification standards include the implementation of the best practices for hygienic design developed by the EHEDG and 3-A SSI.

What additional benefits can Hygienic Design offer food manufacturers in food processing?

In addition to reducing the risk of contamination and complying with food safety standards, food processors and manufacturers can increase their productivity by ensuring that their facilities and processing equipment are built according to the principles of hygienic design.

Cleaning is one of the most time- and resource-intensive aspects of operating a food manufacturing or processing facility. According to a study, half of the companies in the food industry spend at least 10% of their annual revenue on cleaning.

Food processing facilities that comply with the principles of hygienic design help to accelerate thorough cleaning processes and reduce the time and cost for companies to disinfect the machines, which increases their profitability.

Conclusion

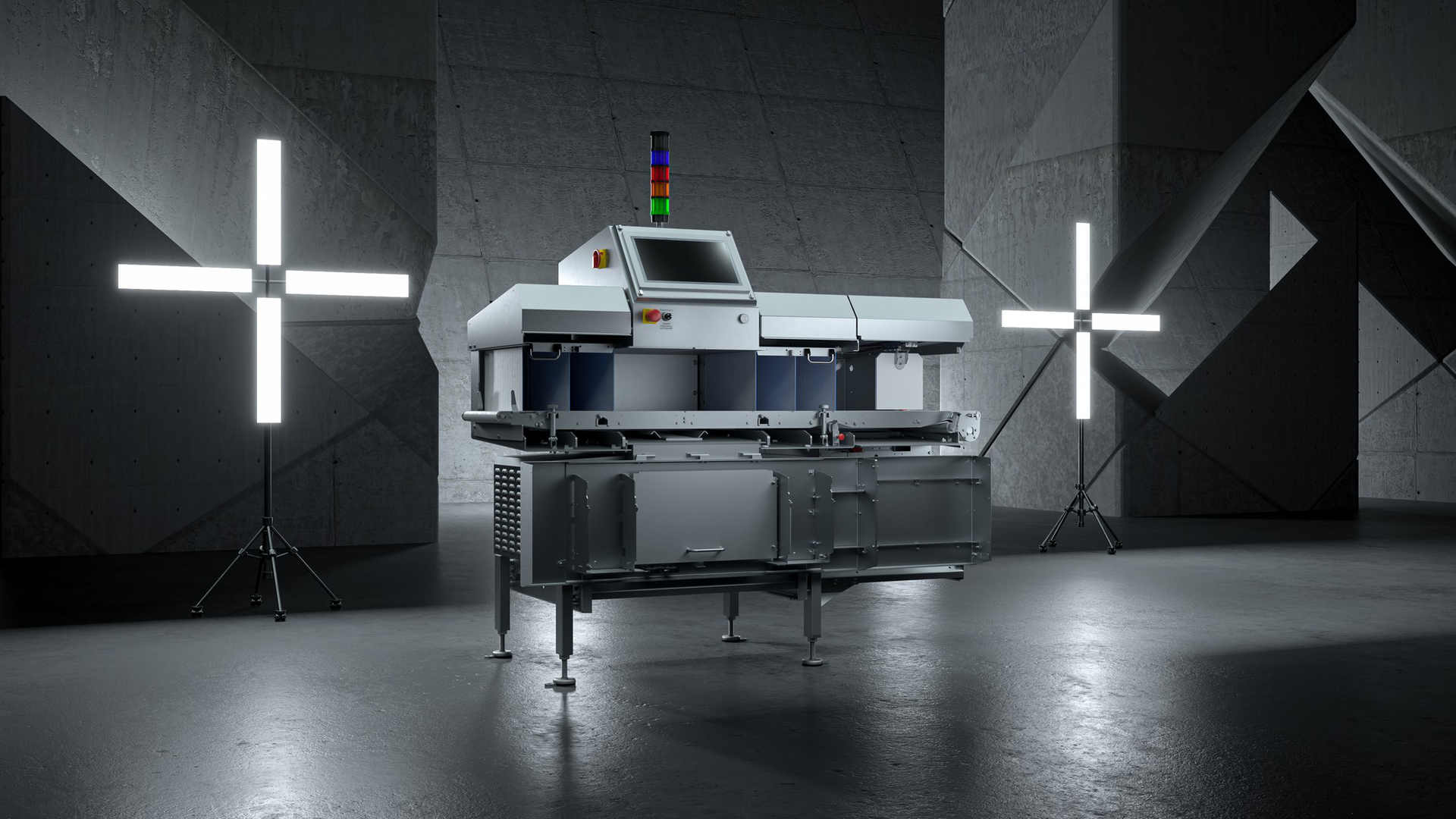

From mixing machines to packaging lines to metal detection systems and X-ray inspection systems, companies in the food industry can benefit by ensuring that their equipment is built to recognized standards for hygienic design.

Hygienic design not only contributes to improving the safety and quality of their products but can also increase a company's profitability by reducing the time and resources required for cleaning and preventing product recalls caused by foreign body contamination.

Since both legal regulations and third-party certification programs evaluate hygienic design, companies in the food industry can also facilitate approvals and certifications by adhering to hygienic design guidelines in their processes.