Coppa Inc., a premium gelato and frozen dessert manufacturer based in London, Ontario, is renowned for its innovative flavors and unwavering commitment to quality. As the company continues to innovate, ensuring product safety remains a top priority. To meet the high standards of food safety, Coppa Gelato sought to integrate Sesotec's "Audit Check" feature into its existing metal detector systems.

Sesotec Canada Ltd, a subsidiary of Sesotec GmbH, leads in the development, manufacturing, and support of foreign body detection and removal for the food industry. "Audit Check" is one of the exclusive features of the integrated compliance software package. Sesotec's INTUITY metal detectors utilize "Audit Check" for automatic monitoring, deviation logging, and alerting personnel to ensure reliable operation and compliance with food safety and quality requirements.

The Challenge: Manual inspection processes are reaching their limits

Coppa Gelato's production line operates at high speed to meet rising consumer demand. While metal contamination is rare, it can occur at any stage of production. This can happen due to equipment wear or accidental introduction of foreign bodies. In light of this and Coppa's commitment to delivering the safest and most delicious products on the market, Coppa recognized the need for a systematic approach to alerting, verifying, and documenting the performance of its metal detectors. The company needed a solution that enhances traceability, reduces the effort of manual testing, and ensures consistent, quantifiable product safety.

Before the upgrade, Coppa Gelato relied on operators to perform hourly checks and manually record the data. Operators tested the metal detector by running test pieces—iron, non-ferrous, and stainless steel—through the system at hourly intervals. While this practice proved reliable, it left room for human error.

Coppa realized that with the company's continued growth and expansion, there was a need to streamline the process and improve the documentation of test results while simultaneously enhancing the overall commitment to food safety.

The Solution: Boost Efficiency with Sesotec 'Audit Check'

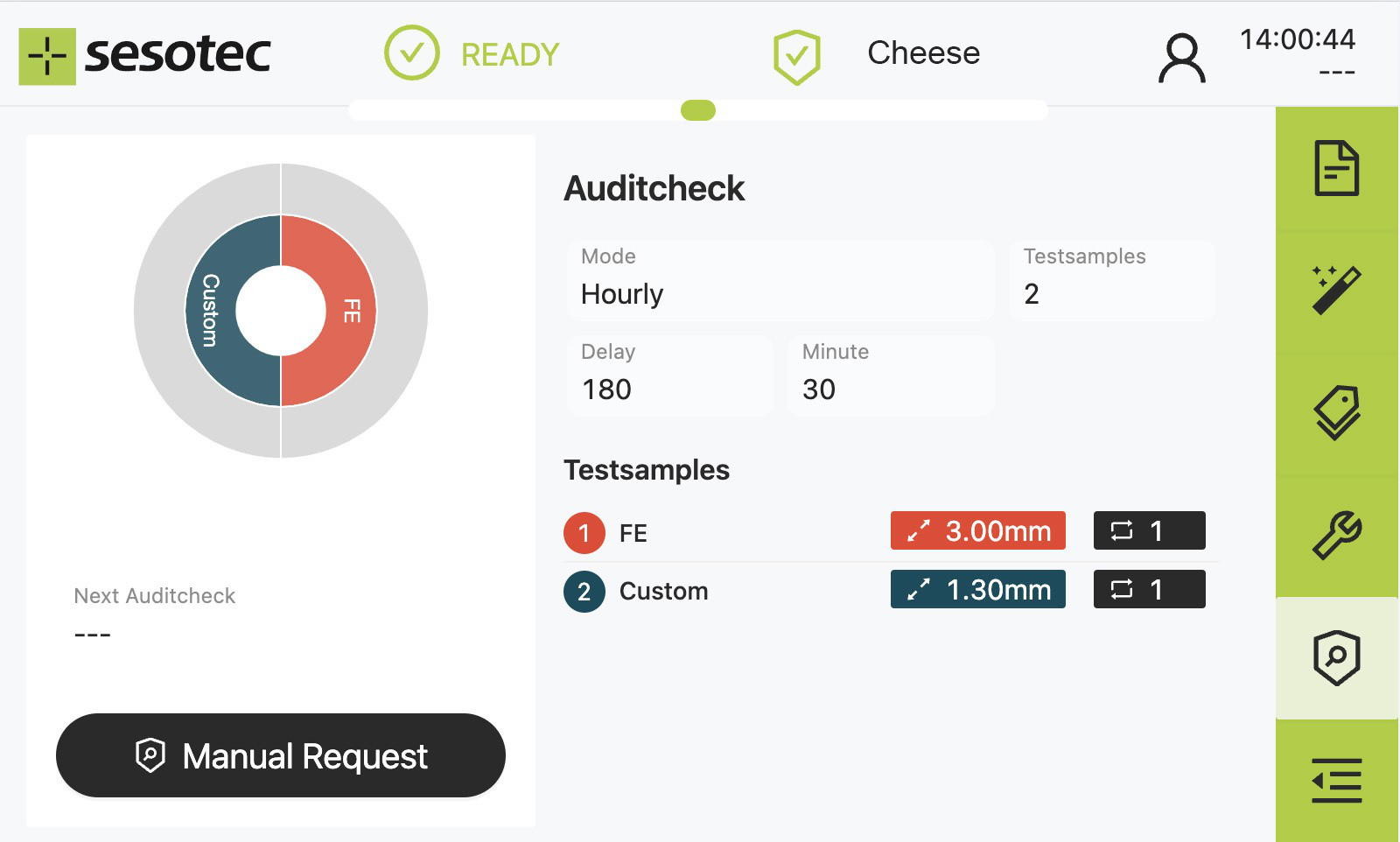

In close collaboration with Coppa's operations manager, Sesotec analyzed the production processes and recommended integrating the "Audit Check" feature to automate and standardize metal detector testing. "Audit Check" provided a customizable setup for testing and verifying metal detection systems. Its design streamlined performance tests and partially automated the testing process while recording performance results without disrupting the production line flow.

To implement "Audit Check," Sesotec worked with Coppa to fully understand the existing process and challenges. Through a cooperative approach, the metal detector was configured with the test specifications needed to meet Coppa's stringent food safety plan requirements. Test samples of ferrous, non-ferrous metals, and stainless steel were passed through the metal detector to confirm both the detector's function and the "Audit Check" functionality.

The system was set up to alert operators hourly and during product changes to ensure reliable operation with regular testing cycles. Operators and QA staff were trained on how to set up and configure "Audit Check" intervals, monitor performance data, and interpret the system's on-screen reports.

The use of "Audit Check" is highly intuitive, offering operators on-screen guidance to navigate their tests. This was a key factor in ensuring a smooth implementation. Additionally, the Sesotec team provided hands-on guidance focused on system setup, operation, and data verification.

Customer Benefits: Enhanced Food Safety, Fewer Errors, Optimized Audits

With the introduction of Sesotec "Audit Check," Coppa has significantly streamlined its food safety processes. The system automatically prompts operators to conduct their tests and guides them through the process, greatly reducing the risk of human error in manual testing. Data recording is now fully integrated into the metal detector's control interface, enhancing traceability and regulatory compliance.

Coppa has achieved greater assurance in detecting and rejecting contaminated products with "Audit Check." The detailed reporting feature simplifies external audits and ensures compliance with local food safety regulations. This added layer of diligence has bolstered the company's reputation for safety and quality in the competitive dessert industry.

Conclusion

By integrating Sesotec's "Audit Check" feature into its metal detection process, Coppa Gelato in London, Ontario, has significantly elevated its product safety standards. The blend of automation, real-time data capture, and comprehensive reporting ensures consistent food safety compliance and customer satisfaction, solidifying Coppa's position as a trusted source for premium gelato and frozen desserts.

Download this case study as a document.