The Istanbul-based Engin Group has established various group companies over the past decades, which are active in the marketing and sales of cosmetics and household products for Turkey and the Caucasus region. The founding of Futurapet in 2020 was a logical step towards sustainability and environmental protection values to which the Engin Group is committed. The recycling of plastic products is another building block for sustainable production that closes the recycling loop and relieves the environment. In a facility equipped with state-of-the-art (sorting) technology, Futurapet recycles plastic waste. The recovered secondary raw materials are fed back into the plastics processing industry.

The requirement: Reliable production of pure-grade PET

When Futurapet was founded, General Manager Oğuz Engin and his team were searching for innovative solutions that efficiently deliver high-quality end products. Only pure rPET can be used for a variety of new products, thus conserving resources and the environment.

The solution: Sorting and material analysis systems ensure purity of types.

Innovative solutions for the entire production line were a decisive factor in the selection of components. Somplast, the distribution partner of Sesotec in Turkey, was able to convince Futurapet as a competent partner and advisor of the function and quality of the Sesotec sorting systems in combination with the new material analysis system.

Futurapet relies on innovative Sesotec technologies: VARISORT+ systems of the new generation, equipped with the unique FLASH technology and a working width of 2816 mm, are used in the multi-stage processing process for bottle sorting. The final sorting of the PET flakes is carried out by the FLAKE PURIFIER+ sorting systems. They deliver PET material of the highest purity and quality. The new FLAKE SCAN analysis system from Sesotec ensures the final inspection of every BigBag leaving the plant.

VARISORT+ for presorting plastic bottles

Futurapet receives plastic bottles compressed into bales. The recycling process begins when the bales are dissolved: First, the lightweight materials are separated by ballistic separators, and then non-ferrous and ferrous metals are removed. After washing and drying processes, the compressed bottles are sent through the Sesotec VARISORT+ sorting systems. These latest generation systems boast a working width of three meters and can thus handle particularly high throughput rates in the respective sorting stage.

VARISORT+ N separates PET bottles from all other types of plastics such as non-PET bottles, labels, or films with a positive sorting. This fraction then passes through a VARISORT+ FLASH CN unit, which is equipped with the innovative FLASH technology for the best possible color recognition. The FLASH technology with transmitted and reflected light units enables color recognition in free fall with the distinction of the finest color nuances in transparent, non-transparent, and semi-transparent materials. The VARISORT+ FLASH CN sorts into three different chutes using two valve strips. The good material PET clear and light blue falls through the natural fall curve into the middle chute.

Non-PET and colored PET fractions are selectively separated into the other chutes. This process is also referred to as negative sorting. All other components are specifically sorted out, and the good material remains in the material stream.

The next sorting step is carried out by another sorting system VARISORT+ FLASH CN. The special feature of this device is that by dividing the three-meter-wide conveyor belt and subdividing it into three chutes, the sorting of six different fractions can be realized. On the left conveyor track, the second sorting step is repeated to achieve a very high degree of purity in bottle sorting for the clear and light blue PET fraction. On the right track, the material discharged from three sorting stages is returned to the first VARISORT+ N sorter via a post-sorting process. Futurapet thus achieves minimal material losses with maximum throughput performance.

Interested in our solutions?

.JPG)

Efficient fine sorting of PET flakes by FLAKE PURIFIER+

After pre-sorting by the VARISORT+ system, the clear PET bottles are shredded. This is followed by washing, drying, and air separation processes. The fine sorting of the flakes is then carried out by the Sesotec FLAKE PURIFIER+ sorting systems, which are equipped with three sensors. Incorrect colors, wrong polymer types, and metallic impurities are reliably and precisely separated from the PET flakes. An additional sorting track allows for further cleaning of the sorted-out material, enabling the maximum amount of high-quality PET to be recovered. Pure and high-quality rPET can be profitably returned to the cycle.

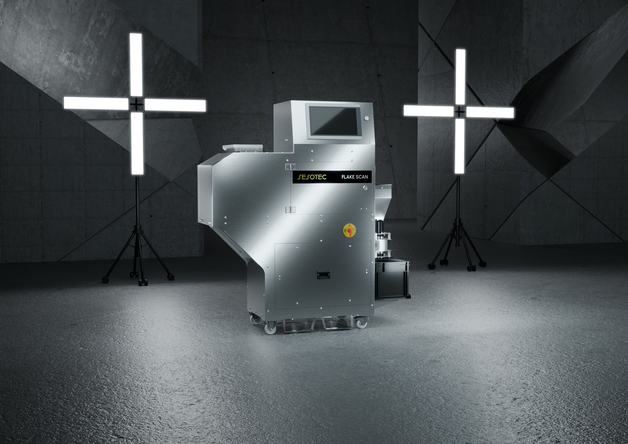

Sesotec FLAKE SCAN material analysis system enables quality analysis in minutes.

Futurapet has set itself the goal of ensuring that only the highest quality rPET leaves the plant. Each BigBag content is checked in the in-house laboratory using a random sample analysis. For this purpose, Futurapet uses the FLAKE SCAN material analysis system from Sesotec. It enables efficient and precise quality analysis of the plastic flakes and quickly provides reliable and reproducible results of the material sample. This allows a decision on the usability of the material to be made in the shortest possible time. The integrated sensors reliably analyze material samples according to plastic types, colors, and metal impurities. Futurapet can supply the plastics industry with rPET flakes of the highest quality and close the recycling loop.

.JPG)

The customer benefit: Highest rPET quality.

Murat Yerli, Vice General Manager at Futurapet: "Sesotec is our partner when it comes to material sorting and analysis. The devices operate with the highest efficiency and deliver the highest quality. This is exactly what we were looking for. We want not only to produce flakes but to produce the highest quality flakes in this field. This is, on the one hand, our contribution to environmental protection and, on the other hand, our contribution to supplying the plastics processing industry with high-quality rPET."

Download this case study as a document.

.JPG)