The optimal X-ray inspection system for a food processing operation should excel in six areas: compliance, safety, operation, hygiene, efficiency, and service.

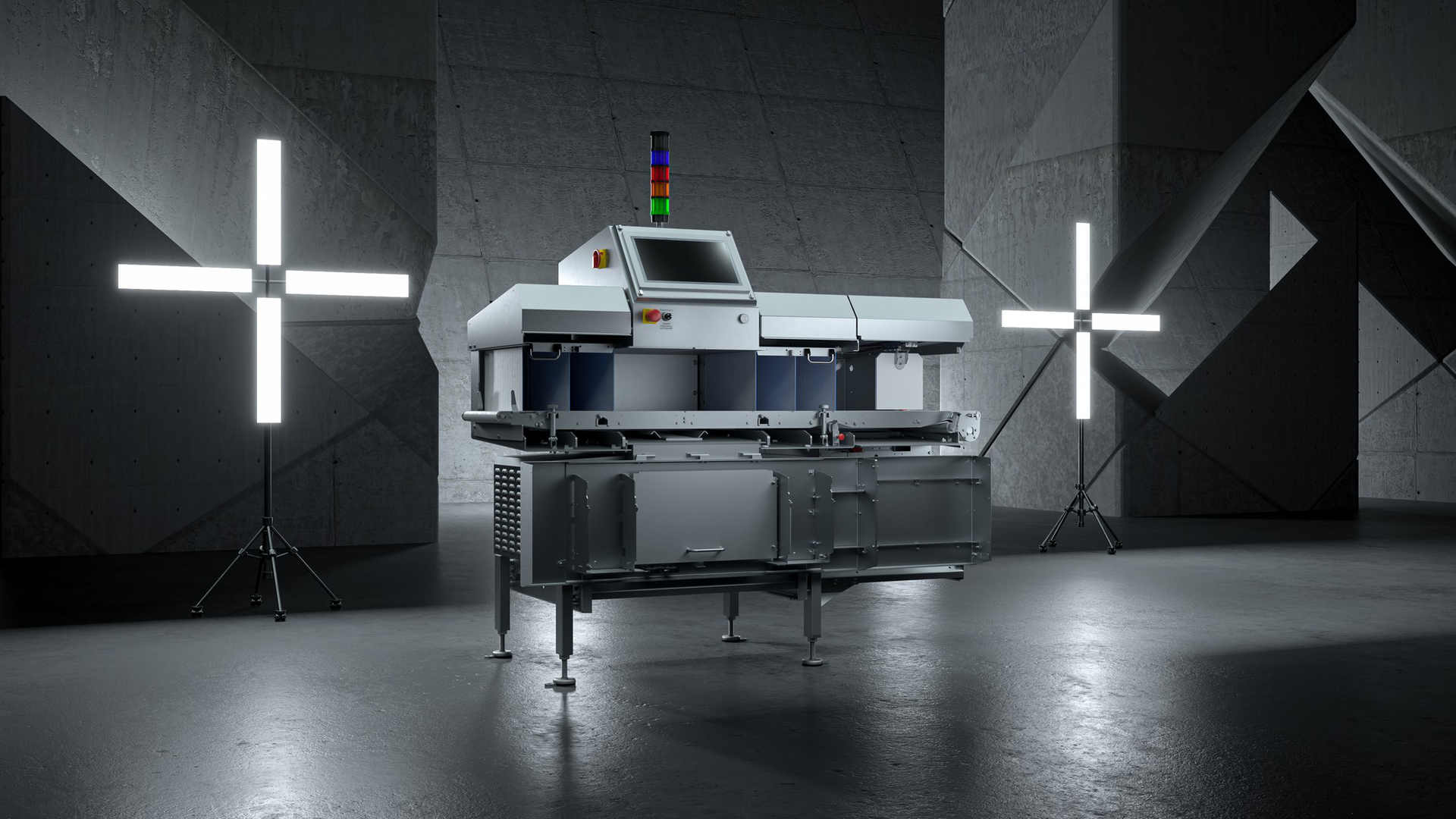

X-ray inspection devices are an indispensable technology for the global food industry, helping to ensure the quality and safety of food. However, although the principles of X-ray detection always remain the same (a beam penetrates the product and creates an image that is evaluated layer by layer by a computer as safe or defective), not all X-ray detection systems are the same. Different X-ray systems can have significant performance differences, which in turn can significantly impact food safety.

To help food manufacturers and processors better evaluate the wide range of X-ray inspection devices on the market and select the optimal system for their production process, the food safety experts at Sesotec have developed a simple six-priority concept:

The 6P Concept

The 6P concept includes six priorities that food processors can evaluate to determine whether an X-ray inspection system optimally meets their overarching food safety goals.

1. Conformity

X-ray inspection devices are a tool to prevent physical contamination of food. To assist manufacturers in complying with legal regulations and third-party standards for food safety, X-ray inspection equipment must be integrated at the identified critical control points and consistently maintain a detection accuracy appropriate to the risk.

2. Security

The system reliably protects employees, products, brand, and data.

In addition to protecting consumers from contamination hazards, X-ray inspection devices should also serve to protect the company that uses them in multiple ways.

On the one hand, the consistent detection of physical contaminants in products is crucial for avoiding product recalls. This, in turn, protects the brand from financial and reputational damage. And to ensure the traceability of food, the data processed by the X-ray inspection devices must be securely stored so that they can be quickly retrieved and referenced.

Furthermore, the X-ray systems must be constructed in such a way that radiation exposure for employees and products is kept as low as possible.

3. Operation

The system is simple and intuitive to use to reduce the risk of human error.

The initial setup of a new X-ray inspection device is always a complex process that must be carried out by an experienced professional. After commissioning, however, an X-ray food scanner should have an electronic interface that is so intuitive that all responsible employees, regardless of their level of experience, can feel confident in operating it. Clear and simple functionality and navigation help to avoid errors and reduce the time and resources required for staff training.

4. Hygiene

The system is designed according to proven hygienic design practices and offers easy cleaning and maintenance.

Like all equipment used in a food processing facility, X-ray inspection devices should be designed to minimize the risk of the device itself becoming a factor for cross-contamination. An X-ray inspection device built according to the proven practices of hygienic design should, among other things, be easy to clean, wear-resistant, and free of areas where moisture can accumulate.

5. Efficiency

The system increases productivity and reduces food waste.

The optimal X-ray inspection device should enhance the productivity of a processing operation rather than hinder it. To achieve this, the system must work reliably with the production pace and should have as few unplanned downtimes as possible. Furthermore, the X-ray inspection devices should be as precise as possible to avoid food waste due to incorrect rejection.

I'm sorry, but there is no content provided under "6. Service" for me to translate. Please provide the text you would like translated.

The system manufacturer offers comprehensive service and support to ensure continuous performance.

Throughout the lifecycle of an X-ray device, continuous service from the device manufacturer is crucial to ensure that the previous five points are adequately addressed. From support during pre-purchase validation, through the initial installation and calibration of a device, to ongoing maintenance visits, predictive maintenance, and the rapid delivery of spare parts - the scope and quality of services provided by the original equipment manufacturer are critical to ensuring the continuous performance of your device and avoiding unplanned downtime.

Checklist for the Optimal X-ray Testing Device

The following checklist contains concrete examples of features and specifications that a food processor might consider when evaluating a device according to the 6-P framework:

1. Compliance

- Detection accuracy - The X-ray system meets or exceeds the detection accuracy requirements of common food safety standards. For example, IFS Food V7 requires systems to detect stainless steel particles as small as 0.8 mm.

- In-process integration - The X-ray system can be directly integrated at all critical control points specified in the HACCP plan.

- Documentation - The X-ray system archives inspection data in accordance with traceability protocols.

- Certifications - The X-ray system has, among others, UL and CSA certifications.

2. Safety

- Radiation dose - The radiation of the X-ray system is below 1 mSv/a, a value that poses no danger to employees.

- Safety concept - The device has safety features, such as a safety cover, whose removal automatically shuts off the X-ray beam.

- Data security - The X-ray system uses a secure user login system, such as RFID, to protect data.

3. Operation

- Ergonomics - The user interface of the X-ray system is easy to use (e.g., touchscreen operation, height position, readability, RFID login)

- Intuitive design - The user interface of the X-ray system is easy to navigate, requires no prior knowledge, and has a self-learning function.

- Multifunctional - The interface of the X-ray system can automatically inspect different products on the same line.

4. Hygiene

- Accessibility - The X-ray system has features such as tool-free access to the conveyor belt, which simplifies cleaning and maintenance.

- Hygienic design - The X-ray system is designed to reduce cleaning effort, for example, by eliminating radiation protection curtains.

- Hygienic materials - The X-ray system is made of materials that are proven to be food-safe, wear-resistant, and suitable for wet cleaning.

5. Efficiency

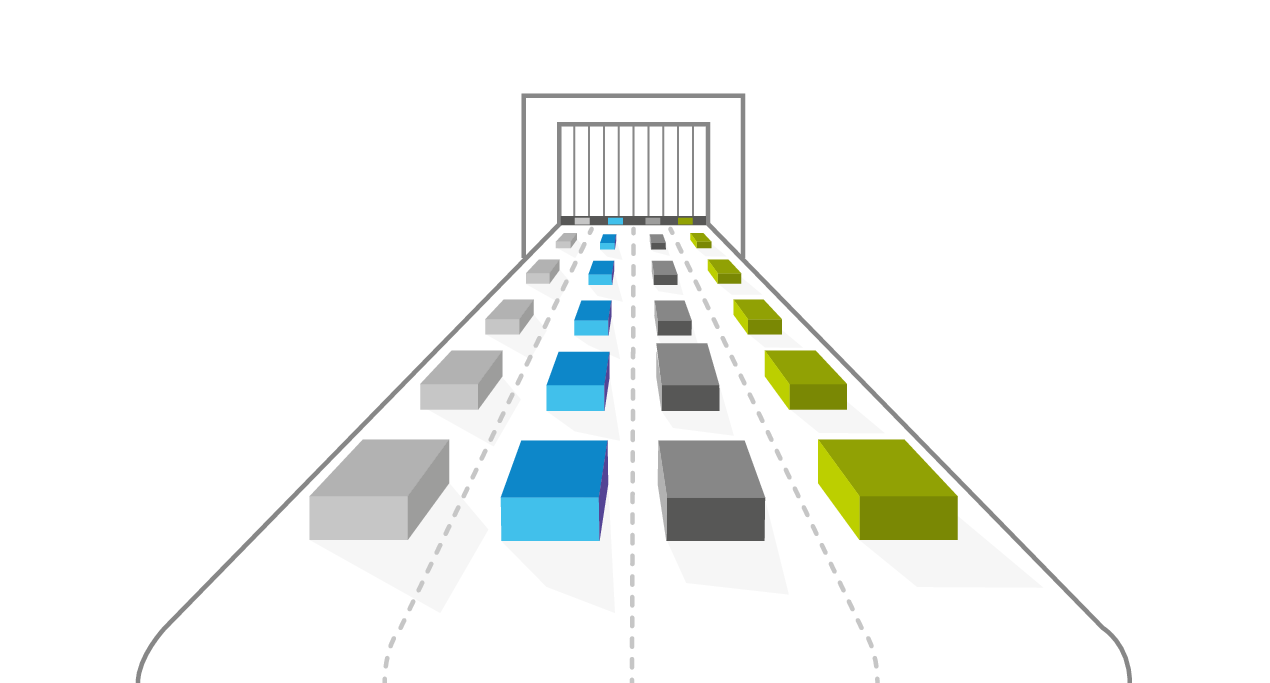

- Operating speed - The X-ray system can process goods in line with production through parallel lanes and high conveyor speeds.

- Sensitivity - The X-ray system can be configured to detect other defects such as underweight and overweight packages, broken and deformed products.

- False reject rate - The X-ray system has demonstrably low false rejects, thus reducing food waste.

- Predictive maintenance - The X-ray system provides early warnings of maintenance needs, such as when the X-ray source needs to be replaced.

6. Service

- Before purchase - The manufacturer of the X-ray system provides support for validation

- After purchase - The manufacturer offers installation and configuration services as well as training materials for employees.

- Technical support - The manufacturer provides comprehensive remote support and on-site maintenance as well as service packages for spare parts and replacement devices.

- Warranty - The manufacturer offers comprehensive warranty and service packages for every phase of the device's lifecycle.

Conclusion

To adequately support food safety in a processing plant, an advanced X-ray inspection device should fully meet all areas addressed in the 6-P concept. Over time, deficiencies in any of these six aspects can lead to significant performance issues that have negative consequences for food safety and the company.

On the other hand, X-ray inspection devices whose design, functionality, and service carefully adhere to each of the six priorities can provide your company's food safety management with reliable and long-lasting performance.