Act Smarter. Produce Sustainably.

With our AI-driven solutions, THiNK and SUSTAiN, we transform industrial processes to be smarter, safer, and more resource-efficient. Whether in the food, plastics, or recycling industries, our AI technologies empower you to achieve quality and sustainability goals efficiently—data-driven, future-focused, and proven in practice.

Optimized Decisions

Through Intelligent Data Analysis

Boosting Sustainability

and Resource Efficiency

Future-Proof Technologies

for Enhanced Competitiveness

THiNK Technologies

Rethinking Smart Detection – THiNK technology for metal detectors and X-ray inspection systems analyzes, learns, and safeguards your production with every inspection.

SUSTAiN Technologies

Enhance sustainability with smart data – SUSTAiN technology for sorting systems connects processes, delivers insights, and promotes resource-efficient actions.

Product Inspection with Artificial Intelligence

THiNK Technologies

THiNK represents the evolution of traditional detection through adaptive algorithms. This technology not only analyzes grayscale changes but also identifies deviations from a product's ideal state.

The AI models are trained live directly in the customer's environment—without any production downtime. Customers can conduct training themselves, anytime and anywhere. This creates a tailored AI model perfectly aligned with real-world applications—flexible, efficient, and independent.

AI with Real Value

Experience the next generation of product safety: Our adaptive AI software, THiNK, virtually eliminates the product effect, enabling the effective detection of even the smallest foreign bodies. The benefits for you: fewer false rejects, fewer product recalls, less hassle. THiNK also works with metallized packaging.

AI-Driven Anomaly Detection

Detect impurities that barely differ in grayscale from the perfect product—undetectable by traditional methods, but easily identified with THiNK.

Typical Use Cases

- Clip Detection

- Bone Detection

- RFID Tag

Clip Detection

THiNK identifies contaminants and product defects that are visible to the human eye but have minimal grayscale differences from the good product, making them undetectable with conventional methods, such as sausage clips.

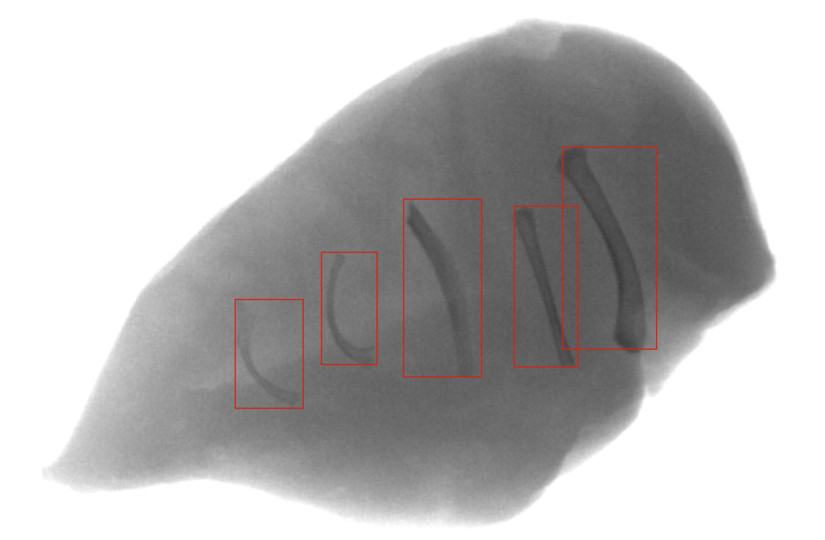

Bone Detection

Detecting bones in fresh meat is challenging due to the low density of bone fragments and the product's inherent inconsistency. This makes distinguishing between bone and meat difficult, especially with traditional inspection methods. THiNK now makes it possible.

RFID Tag

Concealment of RFID tags, such as those on E2 containers filled with meat and sausage products.

Your Benefits

With pinpoint detection and automatic classification by AI, manufacturers can minimize material loss while ensuring the highest product safety. Defective products are precisely sorted out, leaving quality products untouched – a true efficiency boost.

- Increased protection against product recalls

- Reduced food waste

- Enhanced production efficiency

- Improved product quality

- Higher profitability

- Reliable detection for products with high product effects

Material Sorting with Artificial Intelligence

SUSTAiN Technologies

Where high-tech sensors fall short, our AI solutions empower clients to accurately detect and differentiate nearly any material.

Sesotec SUSTAiN Technologies set new standards for intelligent sorting and recycling solutions in the circular economy. NIR-Ai and OBJECT-Ai unlock new opportunities for the global recycling industry.

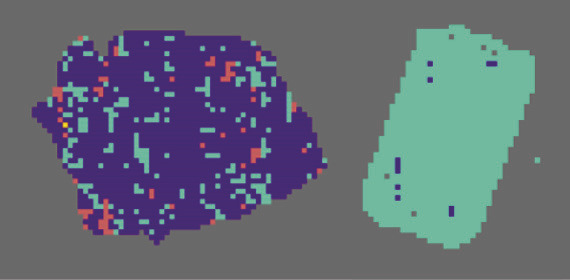

NIR-Ai

For precise differentiation, point clouds defined by the spectral analysis of the near-infrared sensor must be distinctly separate. When significant overlaps occur, as suggested in the image on the left, the risk of misidentification increases. Valuable resources intended for recycling are lost. A typical challenge for NIR sensors: Monolayer and Multilayer PET.

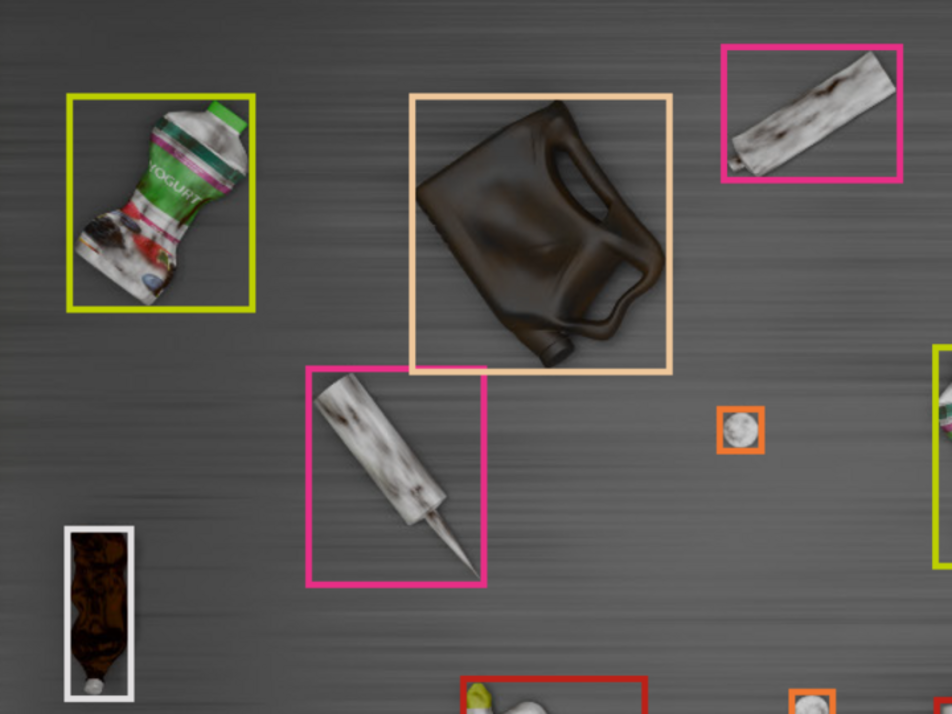

OBJECT-Ai

Harness the power of Artificial Intelligence with our Color Sensor, which assigns specific attributes to each object through advanced color and shape analysis. This ensures precise classification and differentiation of materials based on shape, color, and texture (bounding boxes).

Typical Use Cases

- NIR-Ai

- OBJECT-Ai

Making the Invisible Visible

- Differentiate between PET Monolayer and Multilayer (Tray and Bottle)

- Identify PE Multilayers

- Distinguish HDPE Bottles from Foamed PE

- Enhanced differentiation of PET and PETG (Bottles and Flakes)

- Detect various bottle-label combinations

Note: The list of use cases can be expanded to meet customer-specific needs.

Optical Sensor Perfection

- PE / PP

- Films

- Electronic Waste (WEEE)

- Food vs. Non-Food in diverse applications

- Food-grade examples: Juice and milk bottles, HDPE packaging, squeeze bottles (butter, oil, syrup,...), bottle caps

- Non-Food examples: Cleaning and cosmetic containers, silicone cartridges, oil canisters, pipes or cable sheathing

Note: The list of applications can be expanded to meet customer-specific needs.

Food vs. Non-Food with VARISORT+ UNITY

Valuable Downloads for Our AI Products

AI for Sorting Systems

SUSTAiN Technologies

AI for X-ray Inspection Systems

THiNK Technologies

AI for Metal Detectors

THiNK Technologies

White Paper

The Path from Preventive to Predictive Maintenance in the Food Industry

White Paper

How Sorting with AI Methods Elevates the Plastic Cycle to a New Level

White Paper

How Artificial Intelligence Is Taking Food Production to the Next Level

.JPG)

.JPG)