FOREIGN OBJECT DETECTION FOR PASTA

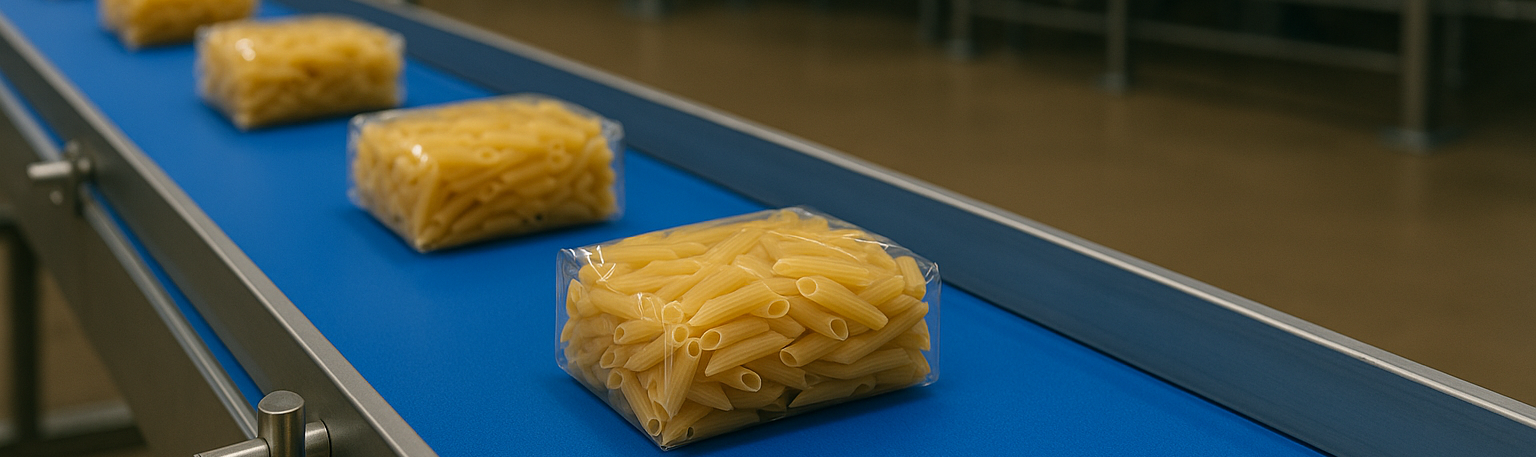

For Pasta that Delights

Perfect pasta starts with perfect safety. Sesotec's detection technology identifies and removes potential contaminants from your pasta. This means less waste and fewer disruptions with greater efficiency. Choose Sesotec for top-tier foreign body detection – ensuring a safe, seamless production and satisfied customers.

The Most Common Foreign Bodies in Pasta

Metal Wear

Wear and tiny metal fragments from machines and conveyors can unknowingly contaminate food products.

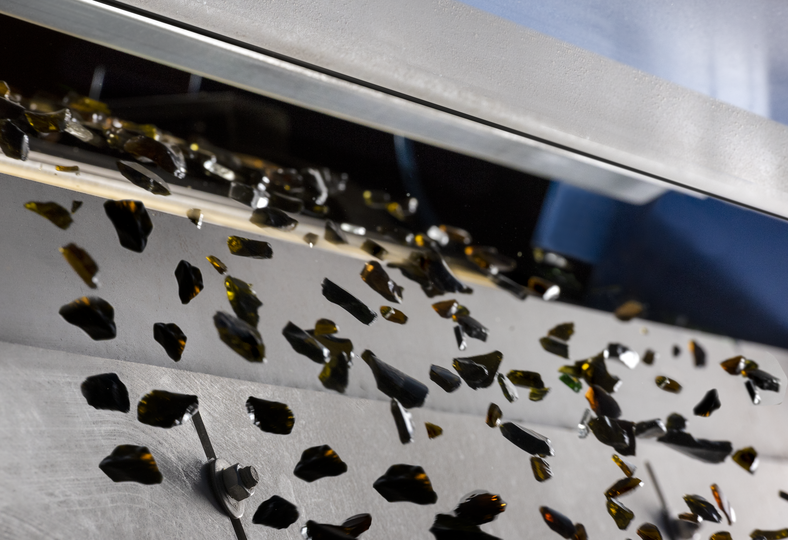

Glass Shards

Glass shards, such as those from broken lights or containers, pose a significant threat to food safety.

Stones

Stones can inadvertently enter the production process during raw material processing.

Plastic Components

Plastics can enter the dough through packaging materials or damaged machine parts.

Equipment Breakdown

When components like metal pieces break off, they can enter the dough and contaminate the product.

Operator Equipment

Small items like glove remnants or pen tips can unintentionally enter the production process.

Metal Wear

Wear and tiny metal fragments from machines and conveyors can unknowingly contaminate food products.

Glass Shards

Glass shards, such as those from broken lights or containers, pose a significant threat to food safety.

Stones

Stones can inadvertently enter the production process during raw material processing.

Plastic Components

Plastics can enter the dough through packaging materials or damaged machine parts.

Equipment Breakdown

When components like metal pieces break off, they can enter the dough and contaminate the product.

Operator Equipment

Small items like glove remnants or pen tips can unintentionally enter the production process.

Foreign bodies in your pasta?

Pasta? Safety First!

- X-ray Inspection

- Metal Detection

- Magnetic Systems

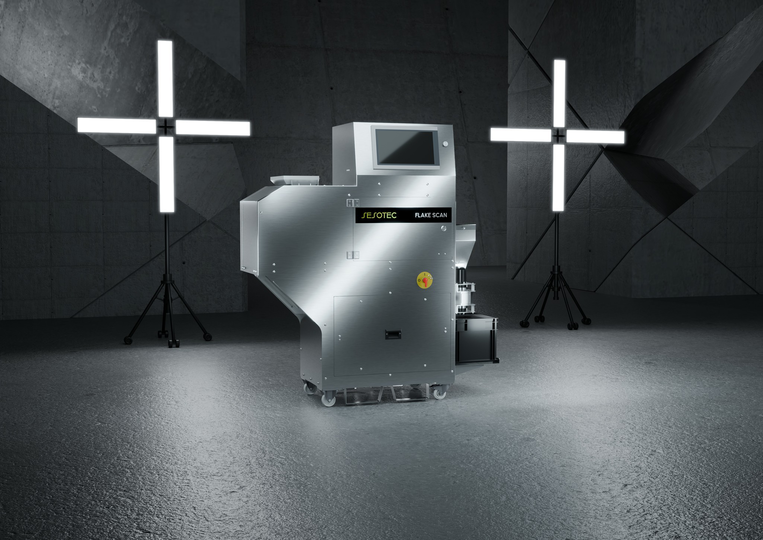

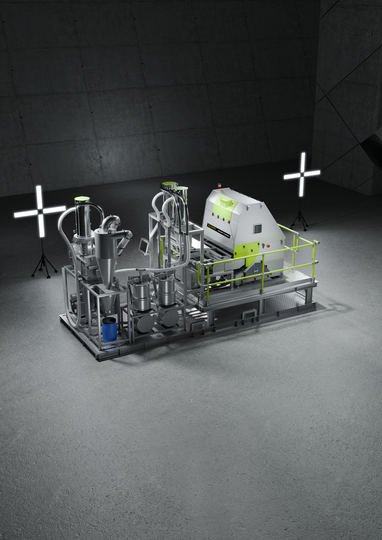

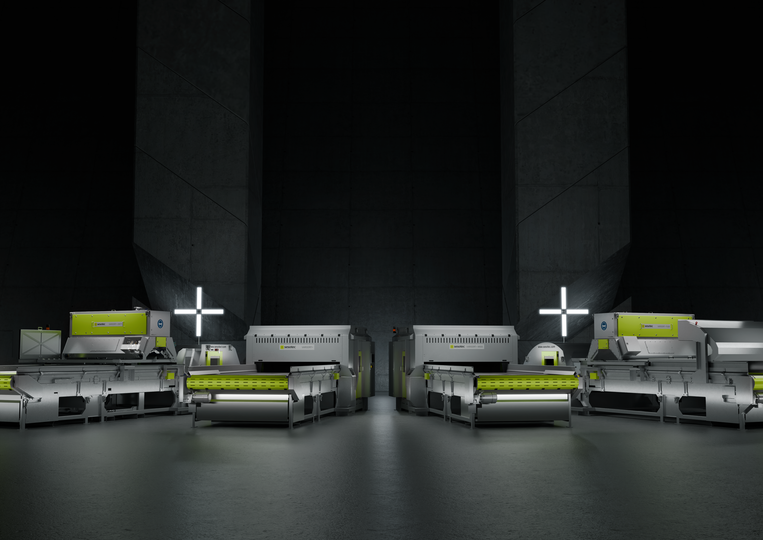

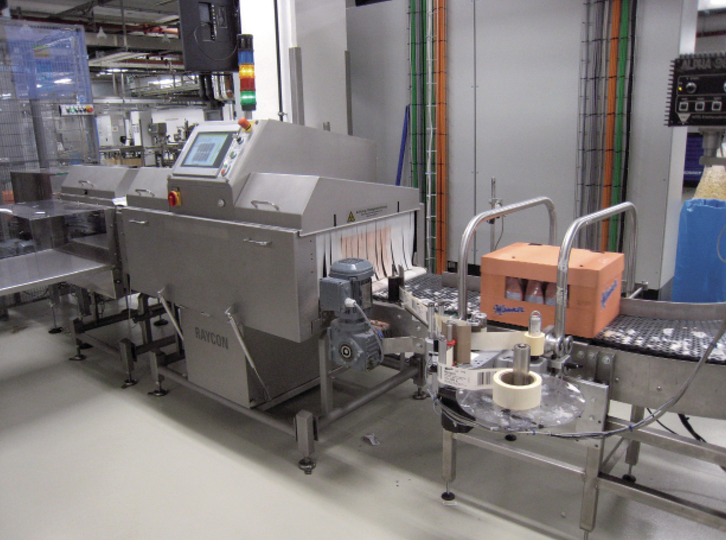

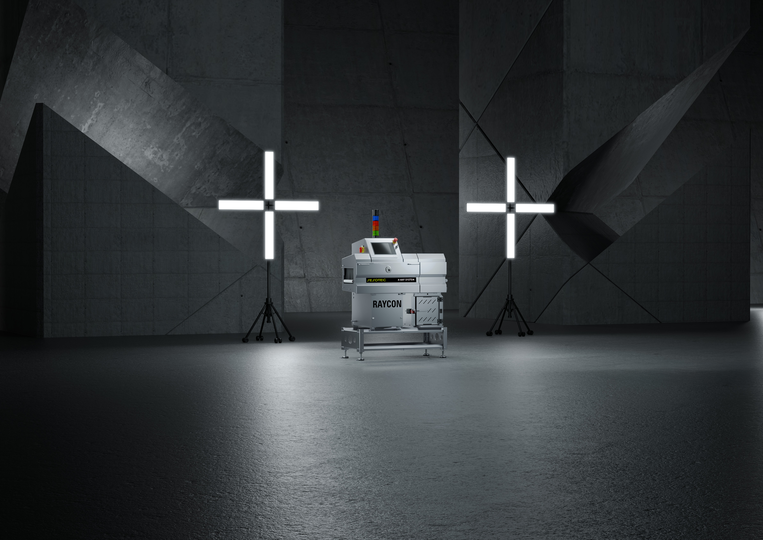

X-ray Inspection

Our X-ray inspection systems ensure precise detection of all relevant foreign bodies in pasta production.

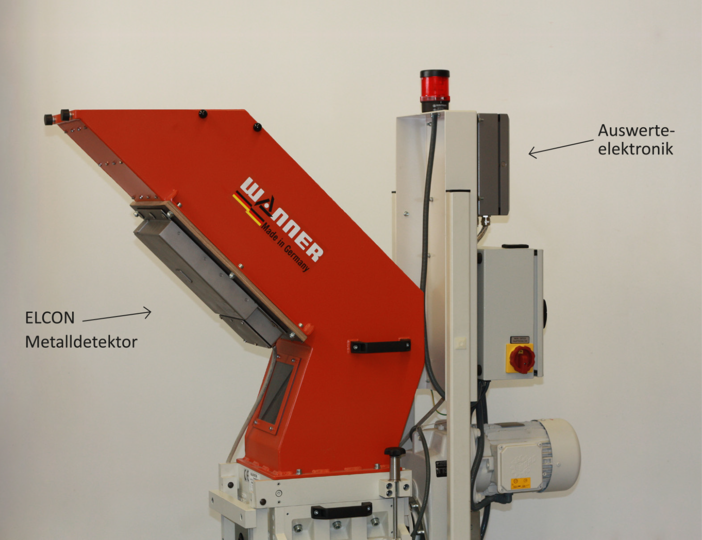

Metal Detection

Sesotec metal detection systems reliably identify metallic contaminants in pasta products.

Magnetic Systems

Sesotec's magnetic systems efficiently remove metallic contaminants like iron filings from pasta products before further processing.

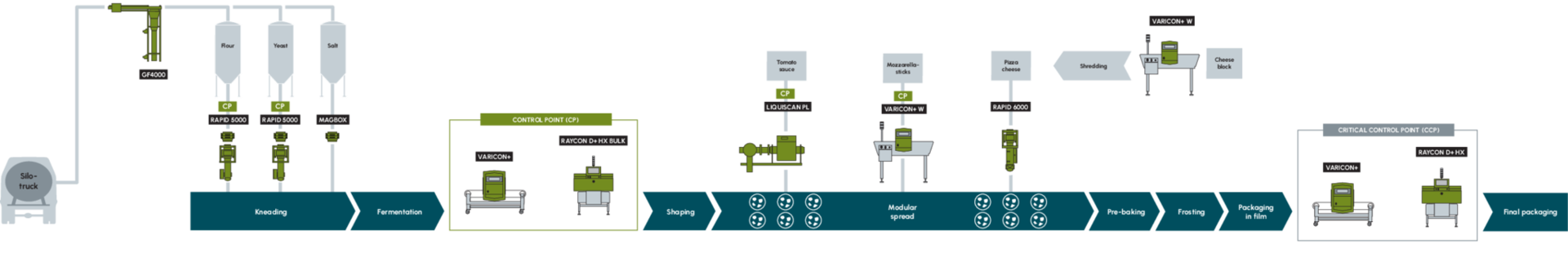

Where Do Pasta Processors Use Our Solutions?

Sesotec's modular foreign body detection systems adapt to your unique needs and are used across a wide range of applications.

Here are some examples:

Raw Materials

Inspect incoming goods to ensure quality of raw materials like flour and semolina.

Dough

Analyze dough during processing, such as before calenders, presses, and die-cutting machines.

Final Product

Ultimate quality control after packaging pasta, spaetzle, or other dough products.

Across the Entire Production Line

From goods receipt to production to dispatch, our metal detection and X-ray inspection systems ensure maximum product purity and safe food production at every stage.

Discover the Perfect Sesotec Solution Here

Interested?

ADD-ONS & SERVICES

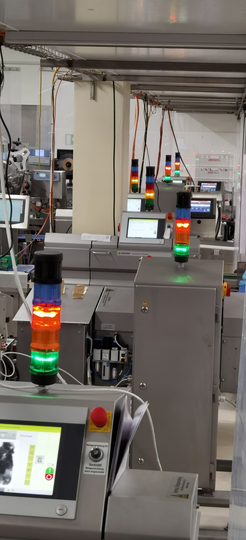

Smart Add-ons for Enhanced Performance

Insight.WEB, the visualization software for metal detectors, -separators and product inspection systems, brings transparency to your production processes, offering a clear overview for enhanced efficiency and increased profitability. Our smart machine monitoring reduces downtime and maximizes your OEE (Overall Equipment Effectiveness).

Centralized Control of

All Sesotec and Third-Party Devices

Clear Visualization & Control

of Your Processes

Maximize Profitability with

Data-Driven Process Optimization

We understand the challenges of pasta production.

CERTIFICATIONS AND AUDITS

Effective foreign body detection is a crucial quality factor in pasta production, especially when it comes to certifications and audits.

LEGAL REQUIREMENTS

EU Regulation 178/2002 and national food laws require manufacturers to implement effective measures to prevent contamination of pasta with foreign bodies.

CUSTOMER REQUIREMENTS

Customers rightfully demand the highest level of product safety from pasta manufacturers. Even the slightest contamination can permanently damage trust in your brand.

PROTECTION AGAINST RECALLS AND DAMAGES

Pasta manufacturers must minimize all risks of recalls, reputational damage, and legal consequences.

Beyond the technical criteria and delivered positive results, the exceptional service and flawless execution were decisive factors in choosing to partner with Sesotec.

Explore Case Studies

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.jpg)

.jpg)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.JPG)

.jpeg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.jpg)