FOREIGN OBJECT DETECTION FOR NUTS, DRIED FRUITS, AND VEGETABLES

Crunchy. Clean. Safe.

Imagine eagerly reaching for a handful of nuts or dried fruits, only for your teeth to crunch down on something hard. Such incidents not only ruin the moment but also risk your customers' trust and your brand's reputation. Sesotec provides the solution: Our high-precision detection systems ensure that unwanted foreign bodies like glass, metal, or stones have no place in your products.

The Most Common Foreign Bodies in Nuts, Dried Fruits, and Vegetables

Metal

Metal parts from faulty machines or tools pose a significant risk to consumers.

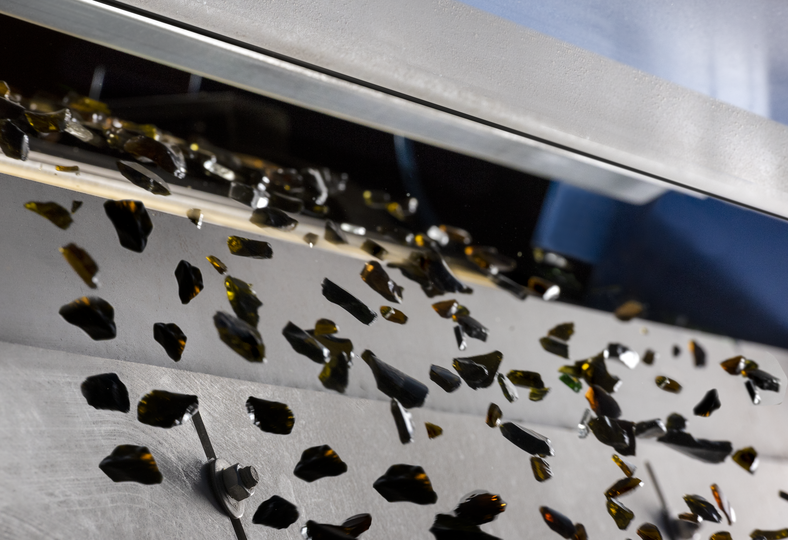

Glass

Glass breakage often occurs due to defective containers or packaging, making glass fragments difficult to detect.

Stones

Stones can enter production during harvest or processing, posing a significant safety risk.

Metal

Metal parts from faulty machines or tools pose a significant risk to consumers.

Glass

Glass breakage often occurs due to defective containers or packaging, making glass fragments difficult to detect.

Stones

Stones can enter production during harvest or processing, posing a significant safety risk.

No more foreign bodies in your dried fruits. Sounds good?

Nuts? Safety First!

- X-ray Inspection

- Metal Detection

- Magnetic Systems

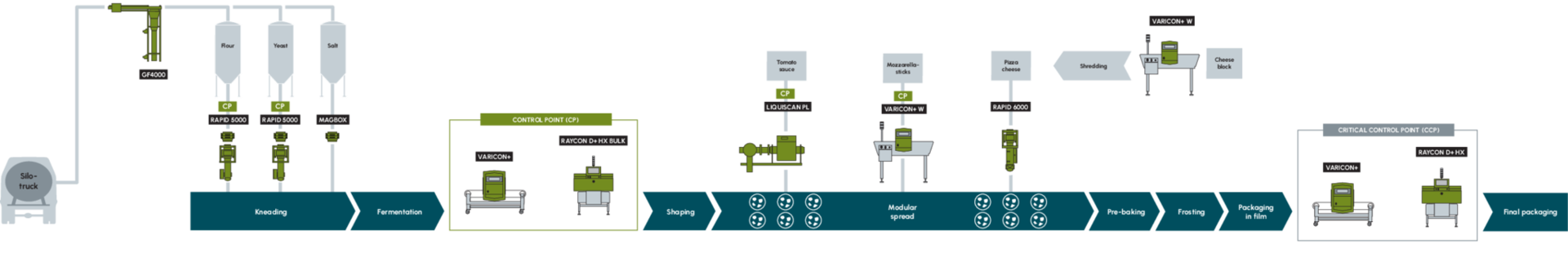

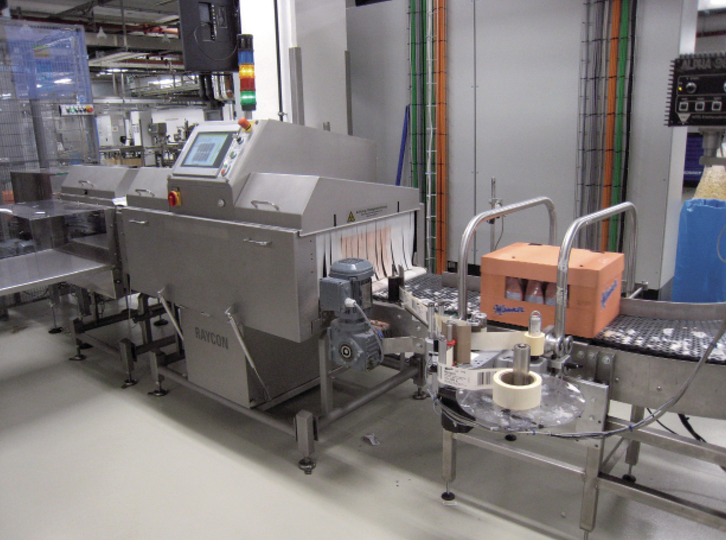

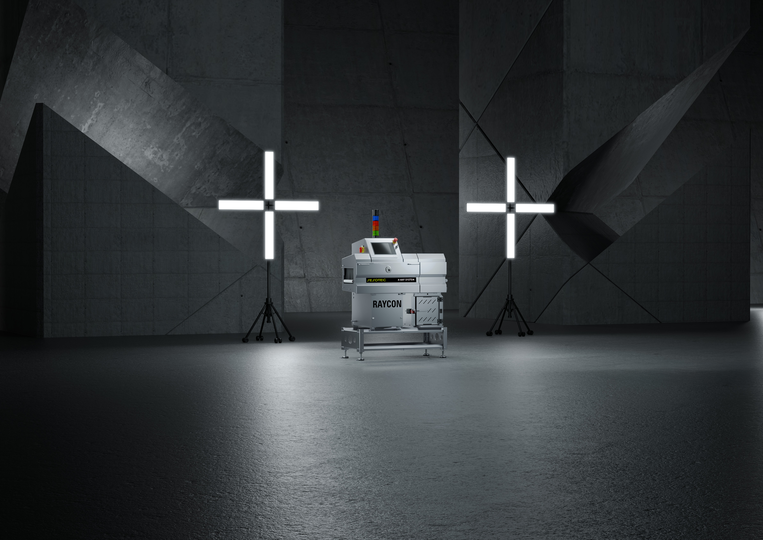

X-ray Inspection

Our X-ray inspection systems detect all relevant foreign bodies during the production of nuts, dried fruits, and vegetables.

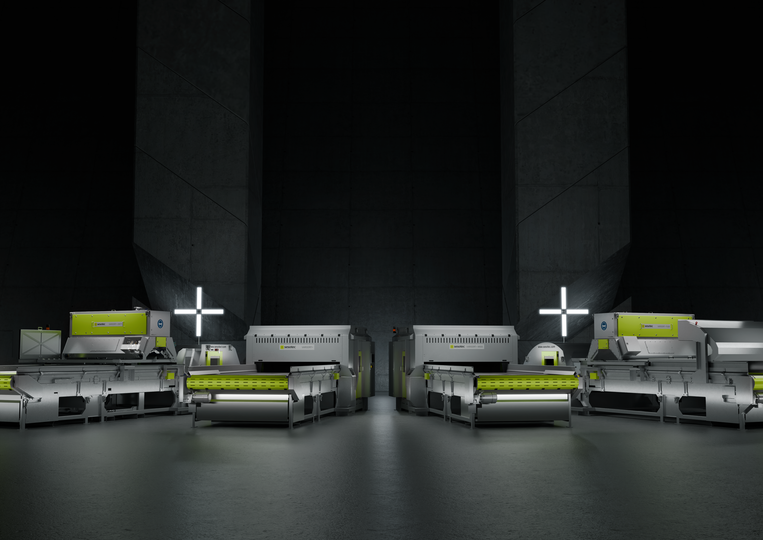

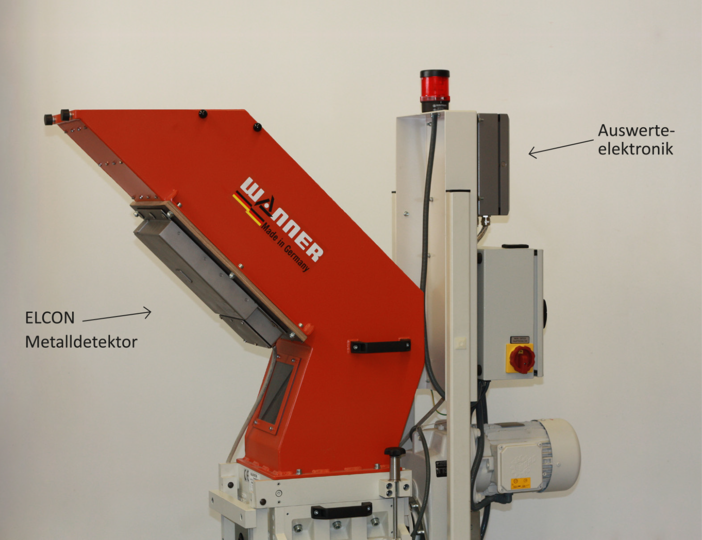

Metal Detection

Sesotec metal detection systems reliably identify metallic contaminants in nuts, dried fruits, and vegetables.

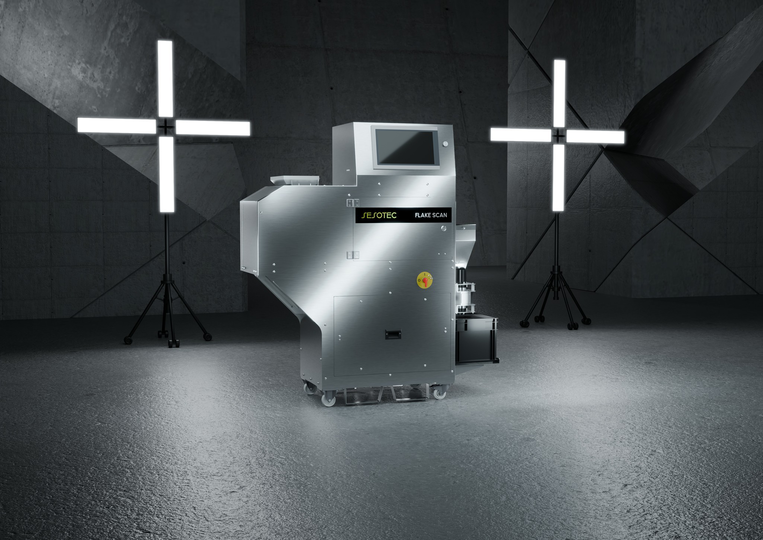

Magnetic Systems

Sesotec's magnet systems efficiently eliminate metallic contaminants like iron filings from nuts, dried fruits, and vegetables.

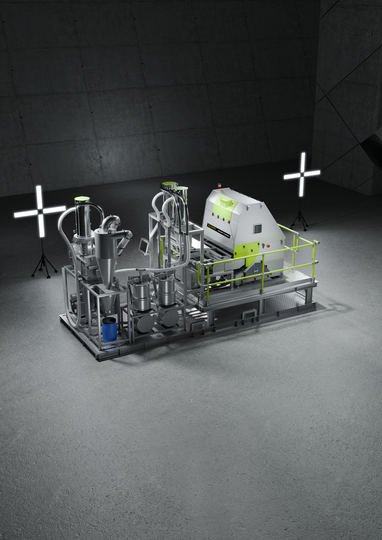

Where do processors of nuts, dried fruits, and vegetables use our equipment?

Sesotec's modular foreign body detection systems adapt to your unique needs and are utilized across a wide range of applications.

Here are some examples of products that can be inspected:

Almonds

Foreign bodies like shell fragments, stones, or metal shards can jeopardize health and product quality. Almonds are often consumed raw or processed. In both cases, foreign bodies must be eliminated.

Pistachios

Shell fragments or other foreign bodies can cause injuries or diminish enjoyment during consumption.

Peanuts

Foreign bodies like shell fragments, stones, or metal can enter the product during harvest or processing.

Banana Chips

During processing, such as cutting and frying, foreign bodies can enter production.

Dates

Foreign bodies like stones, seeds, or plastic fragments can disrupt consistency and pose a health risk when consumed.

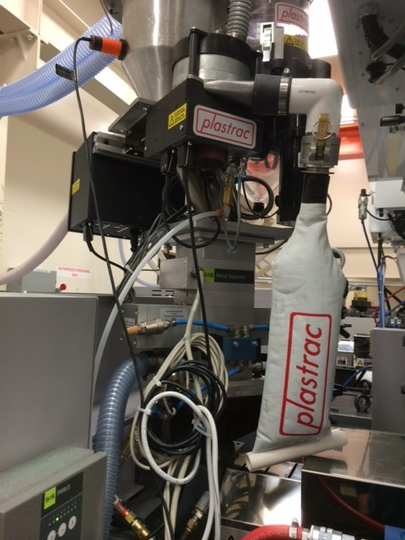

Across the Entire Production Line

From goods receipt to production to dispatch, our metal detection and X-ray inspection systems ensure maximum product purity and safe food production at every stage.

Discover the Perfect Sesotec Solution with Ease

Interested?

ADD-ONS & SERVICES

Smart Add-ons for Enhanced Performance

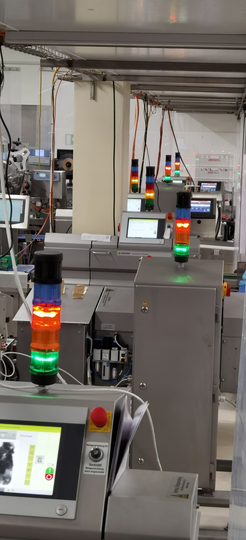

Insight.WEB, the visualization software for metal detectors, -separators and product inspection systems, brings transparency to your production processes, offering a clear overview for enhanced efficiency and increased profitability. Our smart machine monitoring reduces downtime and maximizes your OEE (Overall Equipment Effectiveness).

Centralized Control of

All Sesotec and Third-Party Devices

Clear Visualization & Control

of Your Processes

Maximize Profitability with

Data-Driven Process Optimization

We understand the challenges of processing nuts, dried fruits, and vegetables

CERTIFICATIONS AND AUDITS

Effective foreign body detection is a crucial quality factor for certifications and audits in the production of nuts, dried fruits, and vegetables.

LEGAL REQUIREMENTS

EU Regulation 178/2002 and national food laws require manufacturers to implement effective measures to prevent the contamination of nuts and dried fruits with foreign bodies.

CUSTOMER REQUIREMENTS

Customers rightly demand the highest level of product safety from nut and dried fruit manufacturers. Even the smallest impurities can permanently damage trust in your brand.

PROTECTION AGAINST RECALLS AND DAMAGES

Producers of nuts, dried fruits, and vegetables must minimize all risks of recalls, reputational damage, and legal consequences.

Sesotec currently provides the best technology to meet the high demands of our quality management.

Explore Case Studies

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.jpg)

.jpg)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.JPG)

.jpeg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.jpg)