PRODUCT INSPECTION FOR MILLING AND HULLING PRODUCTS

Not a Grain of Risk

Milling and shelling mills process grain, playing a crucial role in global food supply. The goal is to create a flawless foundation for further processing of grain products. Sesotec detection systems are tailored to the unique demands of the milling industry, offering reliable foreign body detection without halting production.

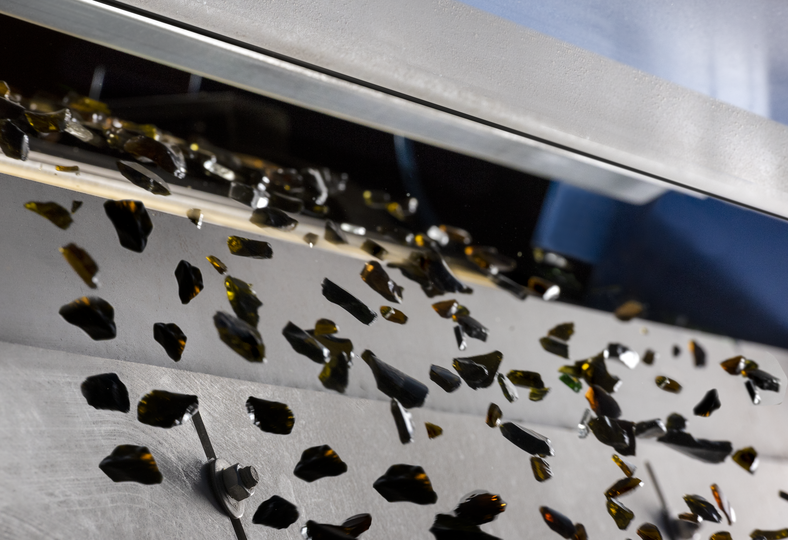

The Most Common Foreign Bodies in Grain Mill Products

Metal Particles and Wear Debris

Metal parts from machines or tools can end up in grain, leading to injury risks and quality defects.

Stones and Minerals

Stones and small mineral particles from the field or during transport can inadvertently enter production and damage the mills.

Wood Pieces and Organic Impurities

Foreign bodies like wood splinters or plant stem remnants can enter the grain during harvest or storage and must be consistently removed.

Insects and Feeding Residue

Insect infestations and contamination from droppings pose not only a quality issue but also a health risk.

Metal Particles and Wear Debris

Metal parts from machines or tools can end up in grain, leading to injury risks and quality defects.

Stones and Minerals

Stones and small mineral particles from the field or during transport can inadvertently enter production and damage the mills.

Wood Pieces and Organic Impurities

Foreign bodies like wood splinters or plant stem remnants can enter the grain during harvest or storage and must be consistently removed.

Insects and Feeding Residue

Insect infestations and contamination from droppings pose not only a quality issue but also a health risk.

Facing challenges with foreign bodies in grain mill products?

Grain? Safety First!

- X-ray Inspection

- Metal Detection

- Magnetic Systems

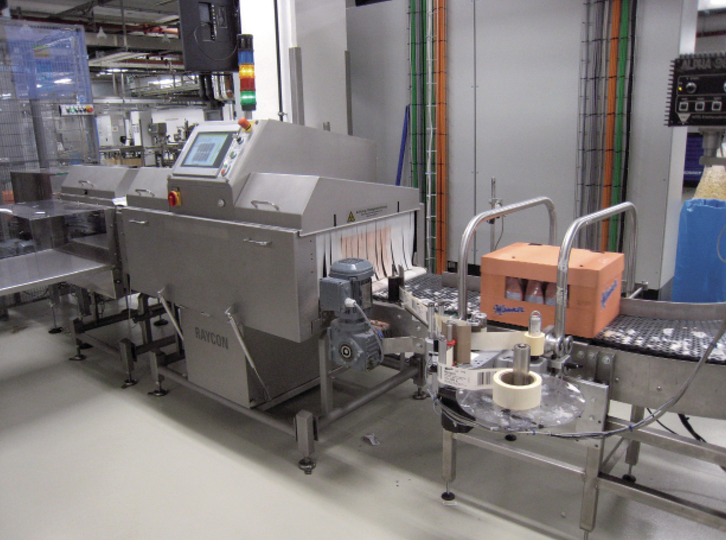

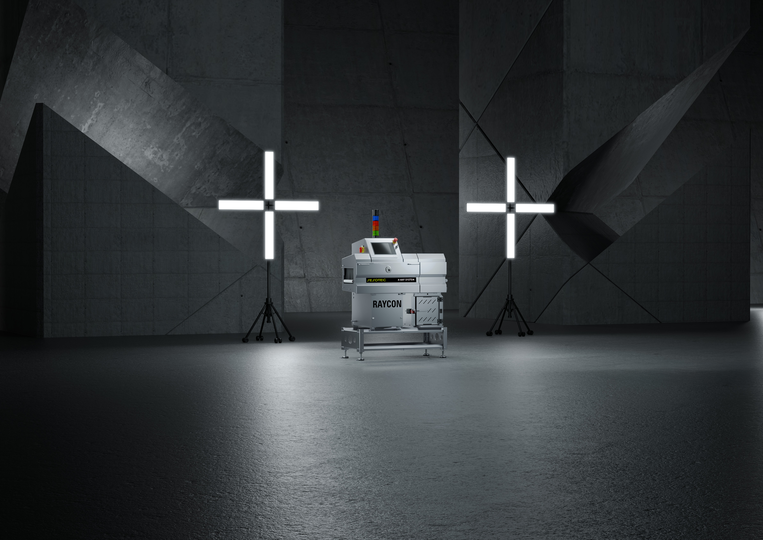

X-ray Inspection

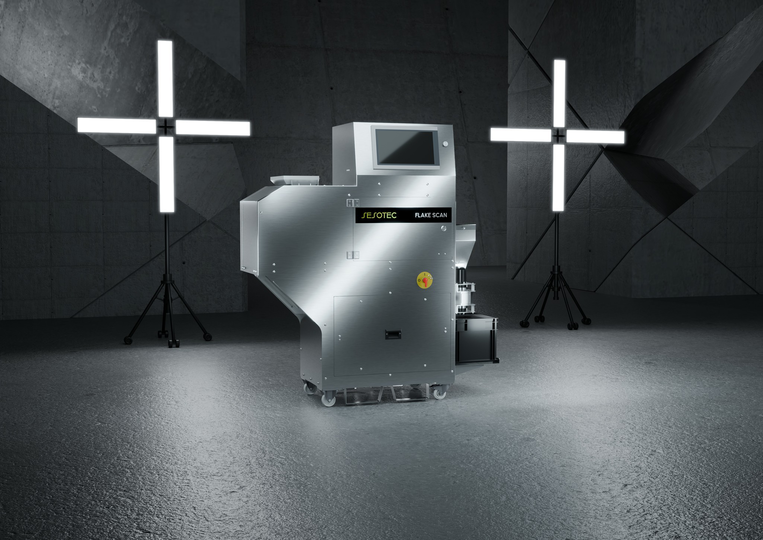

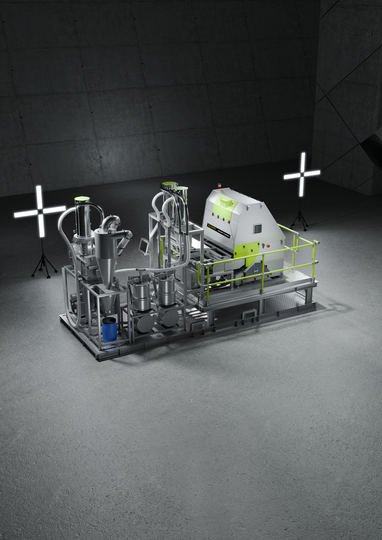

Our X-ray inspection systems ensure the highly precise detection of foreign bodies such as stones, metal shavings, glass fragments, plastic, or wood in the production of grain products.

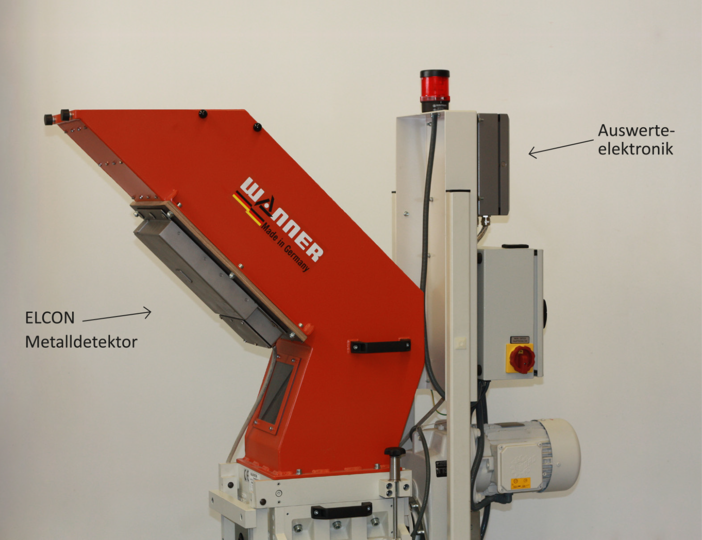

Metal Detection

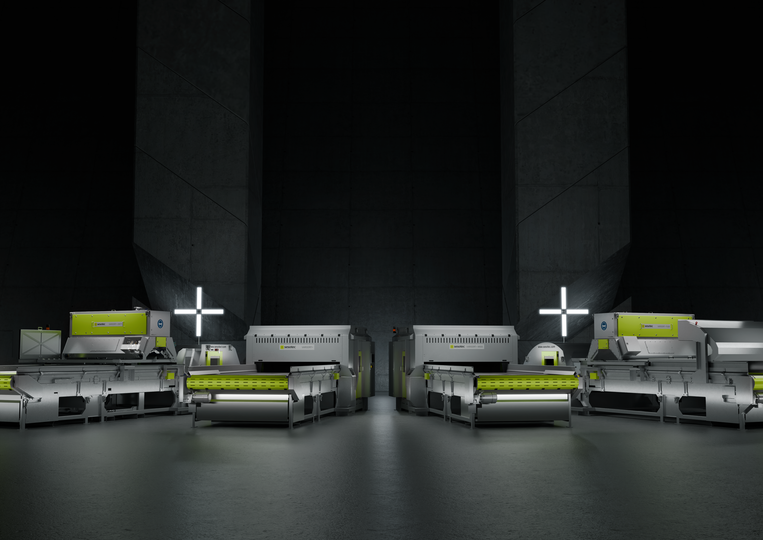

Sesotec metal detection systems reliably identify metallic contaminants in the milling industry.

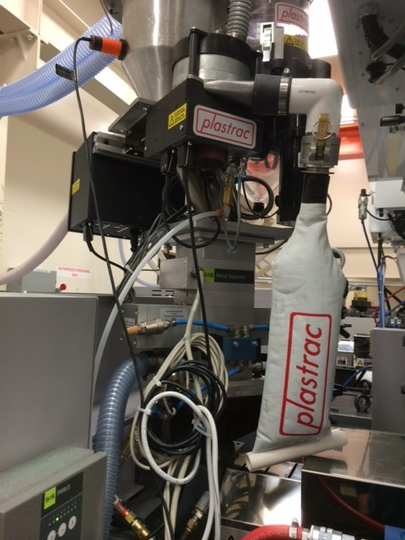

Magnetic Systems

Sesotec's magnetic systems efficiently eliminate metallic contaminants like iron filings from convenience products before further processing.

What grains and grain products are analyzed?

Our modular systems deliver solutions for the milling and hulling industry. Whether your business focuses on oats, millet, or rice:

With industry-leading detection technology and advanced AI features, Sesotec ensures maximum safety and product quality in your production.

Spelt

Spelt is processed as whole grain flour or whole kernels. Foreign bodies can easily be overlooked among the kernels, posing a risk when consumed. Thorough detection ensures pure, safe products.

Barley

Barley is often processed for breweries or as food. Foreign bodies not only disrupt production but also affect the taste and safety of the final product.

Oats

Oat flakes and oat products should have a smooth texture and high purity. Foreign bodies must therefore be consistently avoided.

Millet

Millet is often processed in small grains where foreign bodies are hard to detect. Effective foreign body detection is essential for ensuring optimal product quality.

Rice

Rice is consumed globally in large quantities. Foreign bodies can endanger consumers and render the product unusable. Consistent detection ensures purity and safety.

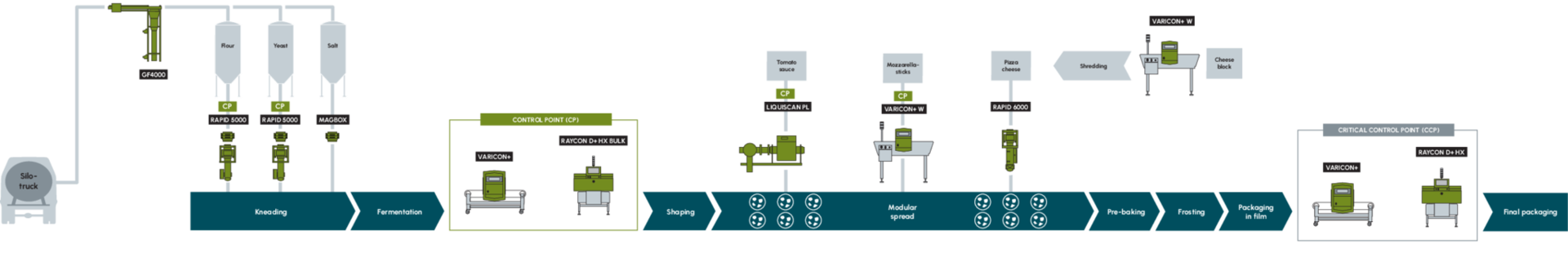

Across the Entire Production Line

From goods receipt to production to shipping, our metal detection and X-ray inspection systems ensure top-tier product purity and safe food production at every stage.

Discover the Perfect Sesotec Solution Here

Interested?

ADD-ONS & SERVICES

Smart Add-ons for Enhanced Performance

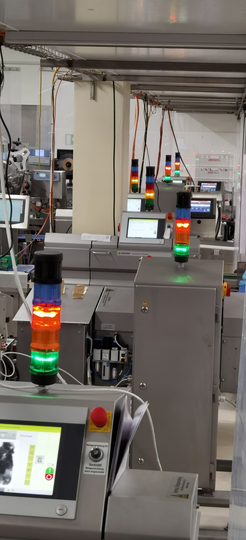

Insight.WEB, the visualization software for metal detectors, -separators and product inspection systems, brings transparency to your production processes, offering a clear overview for enhanced efficiency and increased profitability. Our smart machine monitoring reduces downtime and maximizes your OEE (Overall Equipment Effectiveness).

Centralized Control of

All Sesotec and Third-Party Devices

Clear Visualization & Control

of Your Processes

Maximize Profitability with

Data-Driven Process Optimization

We understand the challenges of producing grain mill products.

CERTIFICATIONS AND AUDITS

Effective foreign body detection is a critical quality factor for milling and peeling products, especially in the context of certifications and audits. Reliable foreign body detection plays a vital role in maintaining hygiene standards and meeting quality requirements according to international standards like IFS or BRC.

LEGAL REQUIREMENTS

Laws like the EU Regulation 178/2002 and national food laws require manufacturers to implement effective measures to prevent contamination of milling and shelling products with foreign bodies. Failure to comply with these legal requirements can lead to consequences such as recalls, fines, or the revocation of operating licenses.

CUSTOMER REQUIREMENTS

Customers rightly demand the highest level of product safety and quality from milling and peeling products. Consumers and trade partners increasingly seek guaranteed safety. Even the smallest impurities can permanently damage trust in your brand.

PROTECTION AGAINST RECALLS AND DAMAGES

Milling and peeling mills must minimize all risks of recalls, reputational damage, and legal consequences.

Sesotec metal detectors with THiNK AI make our products safer, streamline our processes, and boost our production profitability.

Read the Case Study

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.jpg)

.jpg)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.JPG)

.jpeg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.jpg)