CHEESE & DAIRY

Taste the Safety

Cheese factories and dairies know the drill: Food corporations impose strict quality assurance standards on suppliers. Product safety and consumer protection are top priorities. Our systems detect and remove foreign bodies from cheese and dairy products—and can also handle fill level and completeness checks upon request.

The Most Common Foreign Bodies in Cheese and Dairy Products

Metal Wear

Metal wear from abrasion in conveyor systems can silently infiltrate food products, becoming a common source of contamination in production.

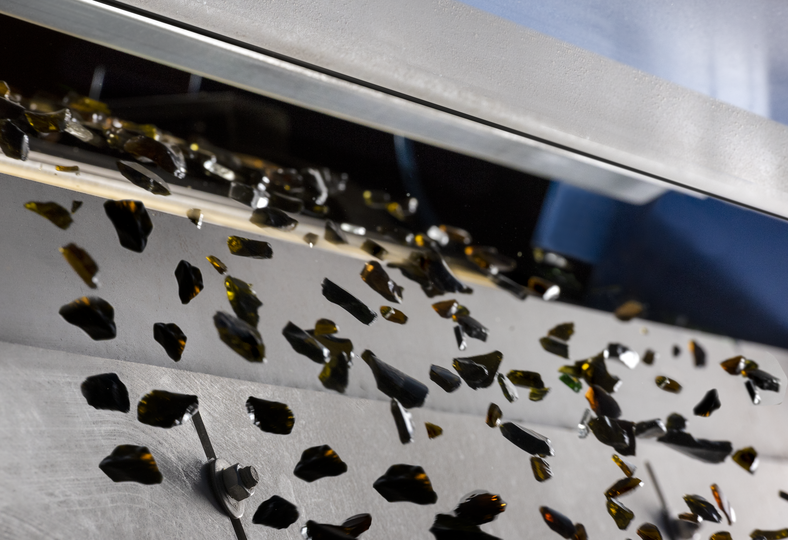

Shattered Glass

Glass shards from broken packaging pose a serious threat to the safety of dairy products and demand immediate detection.

Stones

Stones can inadvertently enter cheese or dairy products through raw materials, significantly compromising product quality.

Plastic Components

Plastic residues, such as those from packaging or machinery, can enter products during production and must be removed through inspections.

Protective Gear Components

Broken pieces of gloves, safety glasses, or other equipment can become foreign bodies and jeopardize product quality.

Metal Packaging Materials

Torn metal pieces (e.g., from yogurt lids) can enter products and demand precise detection.

Metal Wear

Metal wear from abrasion in conveyor systems can silently infiltrate food products, becoming a common source of contamination in production.

Shattered Glass

Glass shards from broken packaging pose a serious threat to the safety of dairy products and demand immediate detection.

Stones

Stones can inadvertently enter cheese or dairy products through raw materials, significantly compromising product quality.

Plastic Components

Plastic residues, such as those from packaging or machinery, can enter products during production and must be removed through inspections.

Protective Gear Components

Broken pieces of gloves, safety glasses, or other equipment can become foreign bodies and jeopardize product quality.

Metal Packaging Materials

Torn metal pieces (e.g., from yogurt lids) can enter products and demand precise detection.

No more foreign bodies in your cheese and dairy products. Sounds good?

Three Technologies, One Goal: Safe Enjoyment

- X-ray Inspection

- Metal Detection

- Magnetic Systems

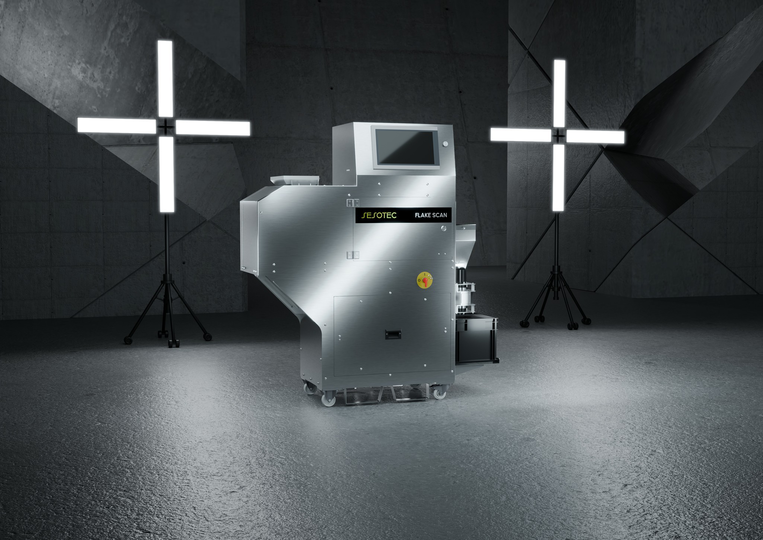

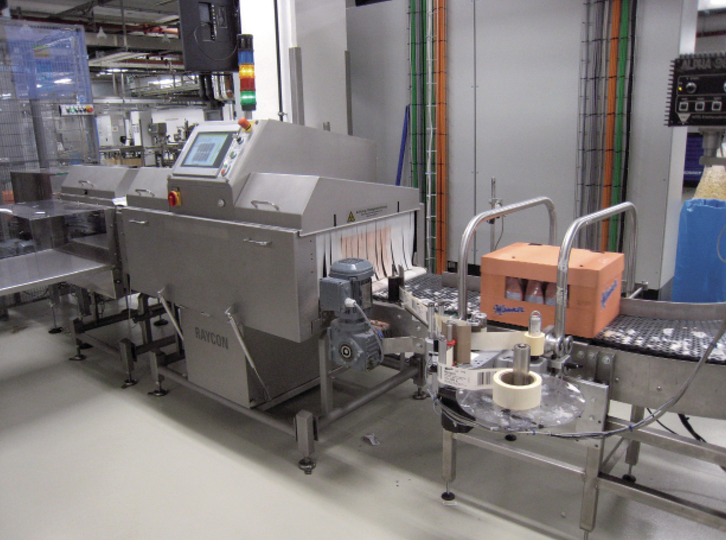

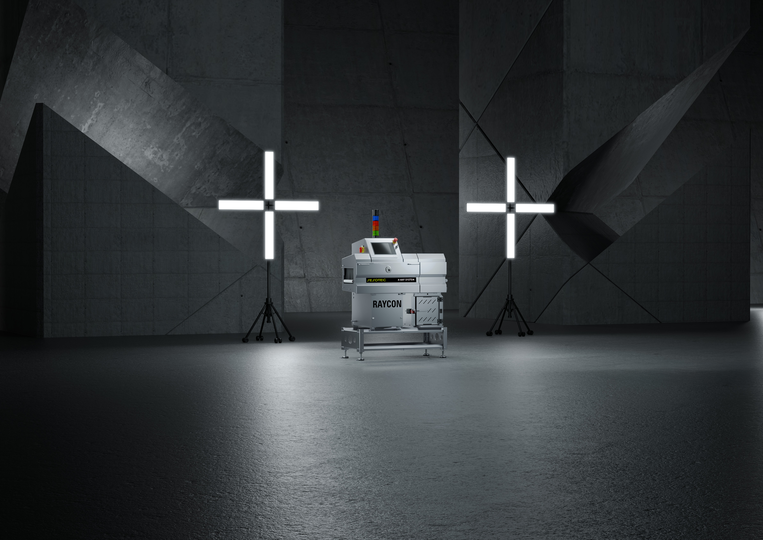

X-ray Inspection

Our X-ray inspection systems ensure the highly precise detection of foreign bodies such as metal, glass, or bone in cheese and dairy products.

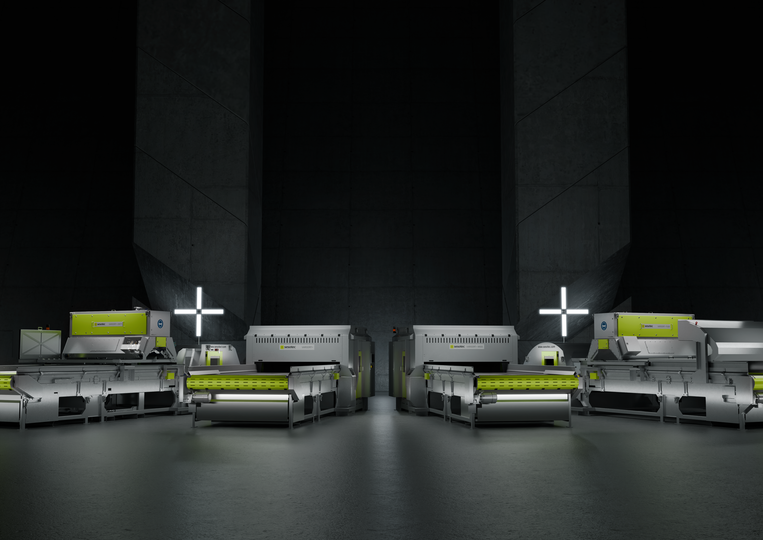

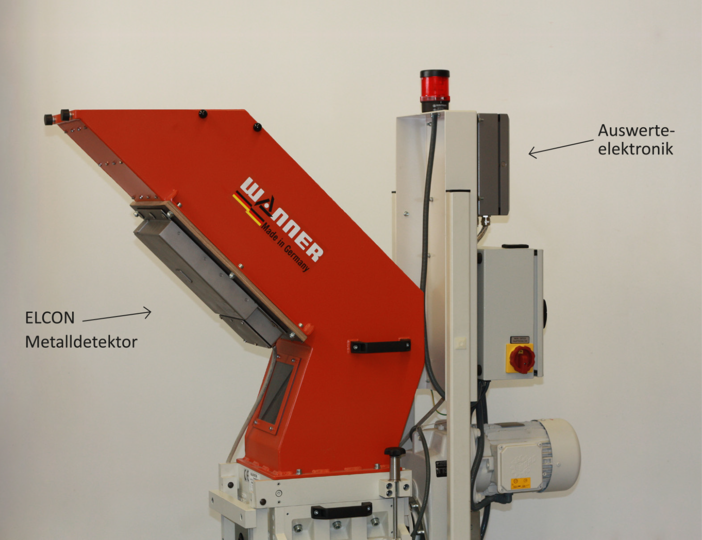

Metal Detection

Sesotec metal detection systems ensure the reliable identification of metallic contaminants in cheese and dairy products.

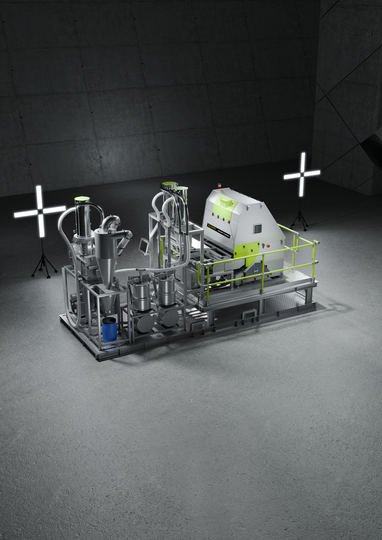

Magnetic Systems

Sesotec's magnetic systems efficiently eliminate metallic contaminants like iron filings from cheese and dairy products before further processing.

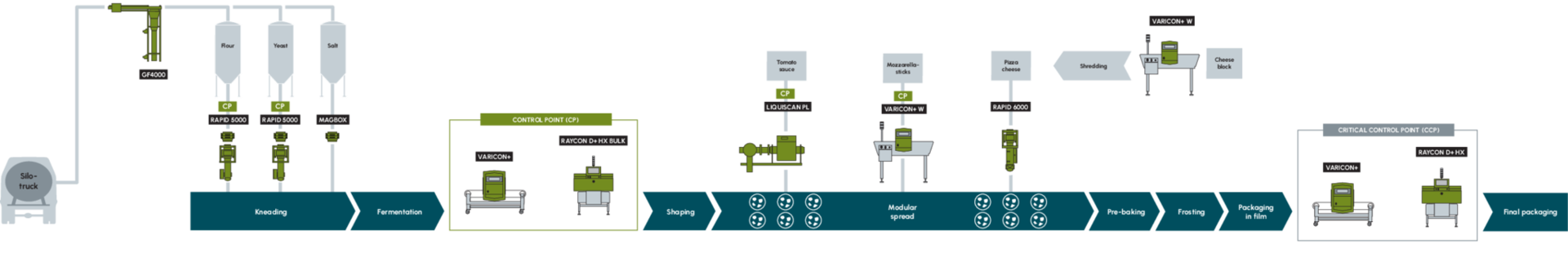

Where Do Dairies and Cheese Makers Use Our Solutions?

Metal detectors and X-ray scanners play a crucial role in the final inspection of packaged dairy products before they are shipped.

Our X-ray systems are not only effective for foreign body detection but also for checking fill levels (e.g., in yogurt or yogurt drinks) and ensuring product completeness. In cheese production, foreign body detectors also help prevent damage to processing machinery.

Curds Before Storage

Foreign body detection in cheese curd ensures that no contaminants enter the aging process, safeguarding the quality and safety of the final product.

Liquid and Pasty Products Before Molding

Before shaping liquid and pasty products, foreign bodies must be detected and removed to ensure smooth processing and eliminate contamination.

Matured Cheese for Slicing or Grating

Foreign body detection in aged cheese before slicing or grating minimizes contamination risks and ensures consistently high product quality.

Yogurt, milk, cream, quark, cream cheese, etc. after packaging

Even after packaging, foreign body detection ensures that dairy products reach consumers in perfect condition and meet the highest food safety standards.

Butter Before Pressing

Purity and quality are top priorities in butter production. Our solutions assist in detecting foreign bodies before the pressing process.

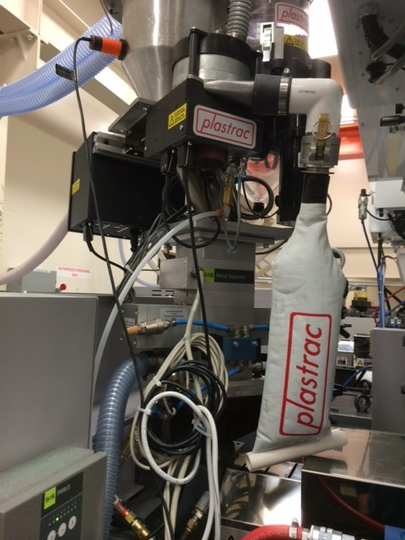

Across the Entire Production Line

From goods receipt to production to shipping, our metal detection and X-ray inspection systems ensure top-tier product purity and safe food production at every stage.

Effortlessly Discover the Perfect Sesotec Solution Here

Interested?

ADD-ONS & SERVICES

Smart Add-ons for Enhanced Performance

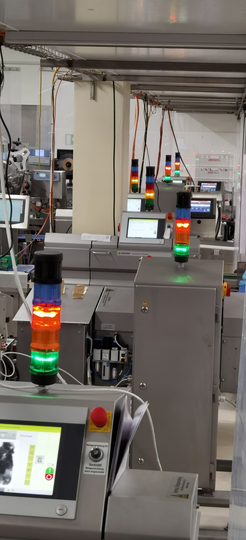

Insight.WEB, the visualization software for metal detectors, -separators and product inspection systems, brings transparency to your production processes, offering a clear overview for enhanced efficiency and increased profitability. Our smart machine monitoring reduces downtime and maximizes your OEE (Overall Equipment Effectiveness).

Centralized Control of

All Sesotec and Third-Party Devices

Clear Visualization & Control

of Your Processes

Maximize Profitability with

Data-Driven Process Optimization

We understand the challenges of the cheese and dairy industry

CERTIFICATIONS AND AUDITS

Effective foreign body detection is a crucial quality factor in cheese and dairy production, especially regarding certifications and audits. Reliable foreign body detection plays a vital role in maintaining hygiene standards and meeting quality requirements according to international standards like IFS or BRC.

LEGAL REQUIREMENTS

Laws such as the EU Regulation 178/2002 and national food laws require cheese and dairy producers to implement effective measures to prevent food contamination with foreign bodies. Failure to comply with these regulations can lead to consequences like recalls, fines, or the revocation of operating licenses.

CUSTOMER REQUIREMENTS

Customers rightfully demand the highest level of product safety and quality from cheese and dairy producers. Consumers and trade partners increasingly seek guaranteed safety, as even the slightest contamination can permanently damage brand trust.

PROTECTION AGAINST RECALLS AND DAMAGES

Cheese producers and dairies must minimize all risks of recalls, reputational damage, and legal consequences.

Sesotec's smart metal detection technologies empower us to make our production processes safe, efficient, and compliant.

View Case Study

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.jpg)

.jpg)

.JPG)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.JPG)

.jpeg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.JPG)

.jpg)