Circular Economy

Mar 18, 2022 |

Promoting plastic recycling - potential for PS and ABS.

What is Polystyrene (PS)?

Polystyrene, or PS for short, is one of the standard plastics and is used - either as a thermoplastic material or as foam (EPS) - in many areas of everyday life. Above all, disposable articles made of polystyrene have become established in the scientific field as well as in many economic and household sectors.

In its solid state, polystyrene is crystal clear, hard, impact-sensitive and electrically insulating. However, it can be colored and printed without any problems. Its physiological harmlessness has also made the plastic attractive to the food sector as visible packaging. Other common applications include disposable drinking cups, lids with spouts for coffee cups or disposable cutlery while yogurt cups or packaging for honey or coffee cream are also produced from polystyrene. Polystyrene is also frequently used in industry settings, for example for component covers, coil formers or switch knobs.

As expanded polystyrene or ESP, also known as Styrofoam, polystyrene is used for the production of take-away packaging or trays and containers for fish, meat, fruit and vegetables. Polystyrene is very cost-effective compared to other plastics. It also has high permeability to gases and water vapor and is odorless and tasteless, which makes it ideal for food storage.

What is Acrylonitrile Butadiene Styrene (ABS)?

Acrylonitrile butadiene styrene (ABS) is the most important engineering thermoplastic in terms of volume. It is a polymer consisting of three monomers - acrylonitrile, butadiene and styrene, whose shape can be changed as often as desired at certain temperatures, and which is moisture- and dirt-repellent and largely resistant to grease and oil, electrostatic charge and temperature fluctuations. ABS is stiff, impact- and scratch-resistant and can also be easily bonded, welded and machined. The plastic is also well suited for coating with polymers or metals. The main applications for ABS plastics are 40% for household appliances and 26% for electrical and electronic (E&E) applications. ABS has also been used in the toy industry for decades: For example, well-known building blocks are molded from acrylonitrile-butadiene-styrene. In the automotive industry, ABS is used, for example, for body parts, trim, spoilers, headlamp lights as well as various interior parts. Last but not least, 3D printing technology has made ABS plastic known worldwide, as the substance is one of the most widely used materials in the 3D printing process.

Recycling potential for PS and ABS

Recycling of PS

Since the properties of polystyrene change only slightly even after repeated processing, it can be recycled very well.

The polystyrene used for packaging in the retail sector is collected by the dual systems throughout Germany. In the sorting plants, hard PS can be easily separated using near-infrared technology. Used EPS packaging containers are also well suited for mechanical recycling. They are collected separately and delivered to the recycling sites as a separate fraction.

Pure polystyrene is mechanically shredded and processed into high-quality recyclate, which in turn is used for the production of various everyday items such as folding boxes, furniture or clothes hangers. Alternatively, the used plastic packaging can be remelted into new products using an injection molding process.

Recycling ABS

ABS is basically very easy to recycle mechanically. The advantage of this plastic is that, as is the case with PS, as a recyclate it retains the same properties as before the recycling process. Here, however, recyclers often face a major challenge. In the case of household appliances or electrical scrap, after the metal fractions have been separated in the sorting plants, what remains is a plastic mixture that not only consists of a wide variety of plastic types, but is also contaminated by dust, wood, pieces of glass, residual metals and other impurities. The task is then to produce clean and recyclable plastic fractions from this complex mixture. Color also plays a major role in the recycling process. Electronic scrap, for example, has a particularly high proportion of black plastics, which in turn are not detected by the near-infrared technology used in sorting plants.

As a result, a large proportion of valuable ABS ends up as waste because of the black coloring. A solution is offered by so-called electrostatic separation technology, which can also separate completely black material mixtures and even achieve purities of up to 99% for ABS fractions. However, this is only possible if the electronic scrap is pre-concentrated, sorting out plastics that contain flame retardants, for example. This pre-concentration of plastics from complex material mixtures requires a combination of dry and wet processing techniques.

Conclusion

Both PS and ABS are, in theory, readily recyclable and can be returned to the plastics cycle. While PS is already being recycled successfully to a large extent and is used in the manufacture of new products, too much valuable ABS still ends up in the trash. The reason for this is that ABS is mainly used for household and electrical appliances, which are complex mixtures of materials, and recycling companies often lack the right sorting technologies to sort these complex mixtures and produce high-quality recyclate, which in turn can be used to create new products.

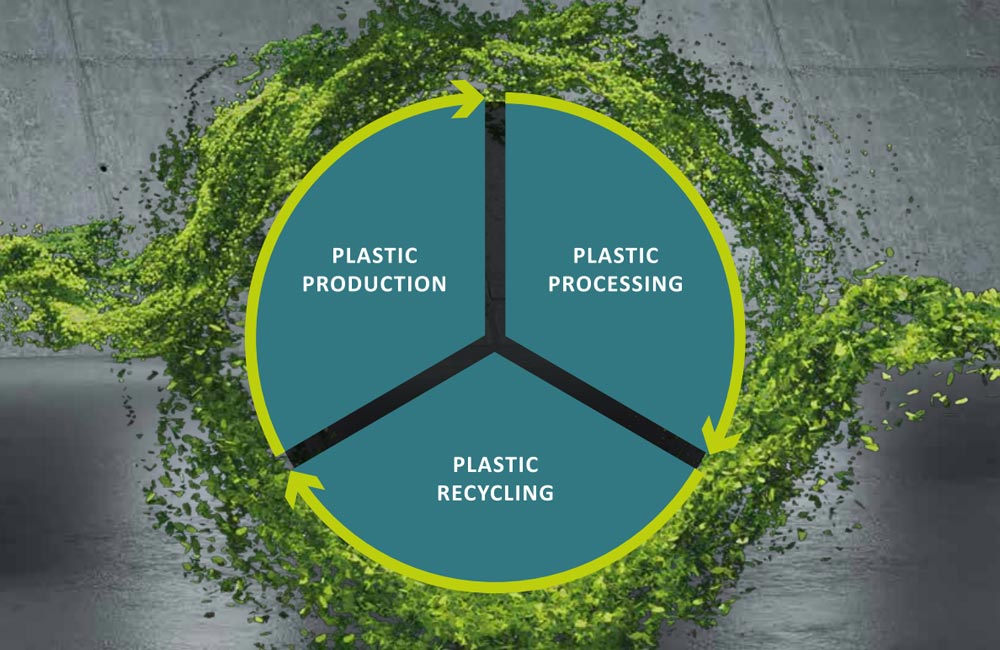

New E-Book: The Circular Economy - Challenges and opportunities for Recyclers and plastics processors

In this comprehensive e-book, you will gain insight into the most important factors of the Circular Economy. In particular, we look at the goal of creating a circular economy that must be profitable not only for people and the environment but also for recyclers, plastics manufacturers and processors.