Do

you want to avoid the risk of metallic contaminants halting production or

ending up in the final product? Our metal detectors reliably detect all

metallic contaminants und provide protection – perfectly tailored to your

application.

Regardless of whether the contaminant − exposed or embedded in the

product − is made of iron, steel, stainless steel or non-ferrous metals, such

as aluminum, copper and brass, our metal detection systems identify all

metallic contaminants using inductive technology (see below). They send a

signal to the process controls and, together with a separation unit, remove the

contaminated products – entirely automatically. Our machines for the food

industry comply with standards such as IFS, BRC and FSMA.

Our complete range of leading technology covers a wide range of products, types of conveyance and process steps. Whenever standard solutions do not provide the right fit, we find another way through customization. Our many years of experience in a variety of user-focused industries enables us to quickly immerse ourselves in your processes and offer solutions that will integrate perfectly into your production line!

In terms of design and development, we focus on making the installation, everyday operation and cleaning of our systems as quick and easy as possible. Our machines and systems also feature a high level of mechanical stability and resistance to interference – quality that is engineered and made in Germany.

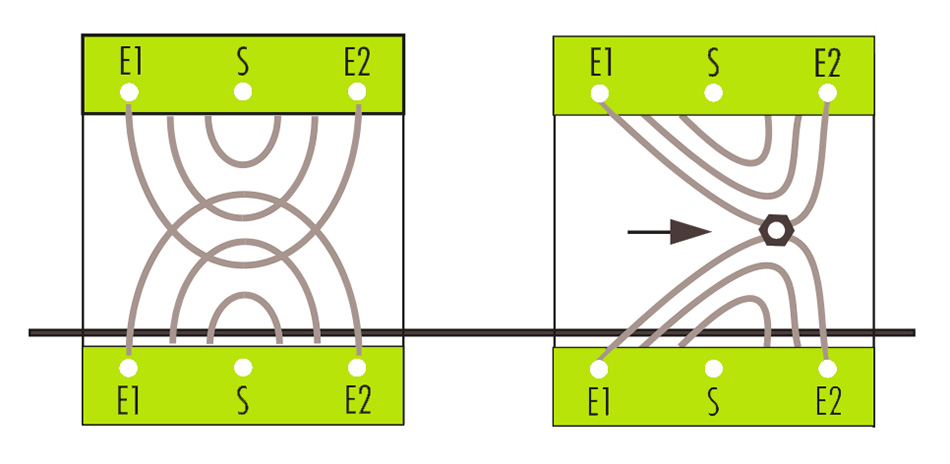

The detection abilities of our metal detection systems are not limited to

iron or magnetic materials, but rather include every type of metal. To make

this possible, they use the transmitter/receiver method based on

electromagnetic induction. While in operation, the metal detector generates a

constant electromagnetic field. If a piece of metal passes through the

detector, it disturbs the field. The signal subsequently received registers as the

presence of metal.

Our control systems therefore use sophisticated algorithms to analyze signals with reference values that either come preset or that are established during ongoing operations. This approach prevents them from triggering false alarms, while enabling them to reliably identify metallic contaminants. If a contaminant is detected, the module (depending on the configuration) sends a signal to the process controls, activates the downstream separation unit, notifies the operating staff and enters the incident into the integrated logbook.

Products with high or fluctuating levels of product effect (due, for example, to metallized packaging or storage in brine or water) can be more reliably inspected with THiNK. False rejects, and the food waste they cause, are reduced. Learn more about THiNK.

Do you still have questions? Are you looking for brochures or technical data sheets? Would you like us to advise you with respect to your specific application? Contact us!

Our technology center also provides the opportunity to test your products with our systems and machines. You can either send us the product for testing, or you can visit in person.

Unser White Paper beschreibt einige der Herausforderungen, die sich

in der Fleischindustrie hinsichtlich der Produktreinheit und -sicherheit

ergeben und erklärt die verfügbaren Technologien, die für die Detektion

von Fremdkörpern zur Verfügung stehen.

Our White Paper informs you about the criteria that

need to be considered when you choose machines and systems for the

protection against contaminants and for metal detection.

Our White Paper describes the development of technologies in

contaminant detection in the food industry.

How easy is it to install the metal detector in the production line – and

how easy is it for your staff to operate the device?

In our white paper, we provide a detailed

outline of the issues, their causes and the necessary countermeasures for

eliminating metal contamination in the plastics processing industry.

In our

e-book we show you, amongst others, what challenges the development of the

world's population and especially food safety pose for manufacturers and

processors and how they can still be mastered.

The Whitepaper explores the challenges that

metal contamination poses to compounding and masterbatch production and

considers the key features that metal separators must have to provide an

adequate solution.

Despite the breadth of technology available for foreign object detection, certain types of food products remain difficult to inspect via conventional methods. The reason for this is that some foods have high levels of product effect, which can interfere with metal detection. This white paper examines the phenomenon of product effect, the problems it can cause, and why artificial intelligence offers an innovative and promising solution.

The plastics industry is under pressure. Between climate change, excessive consumption of finite resources, and vast amounts of plastic waste in the world’s oceans, plastics are coming to be seen in a different light by politicians, businesses, and consumers alike. Read in our e-book about the most important factors of a functioning circular economy, especially which challenges and opportunities exist for recyclers and plastics processors.

This guide is intended to help quality managers and production managers in food processing companies to generate a common understanding regarding validation and verification processes in their own organization and to implement appropriate procedures.

Download

In the new Sesotec White Paper "Using recycled materials in plastics processing" you will learn about

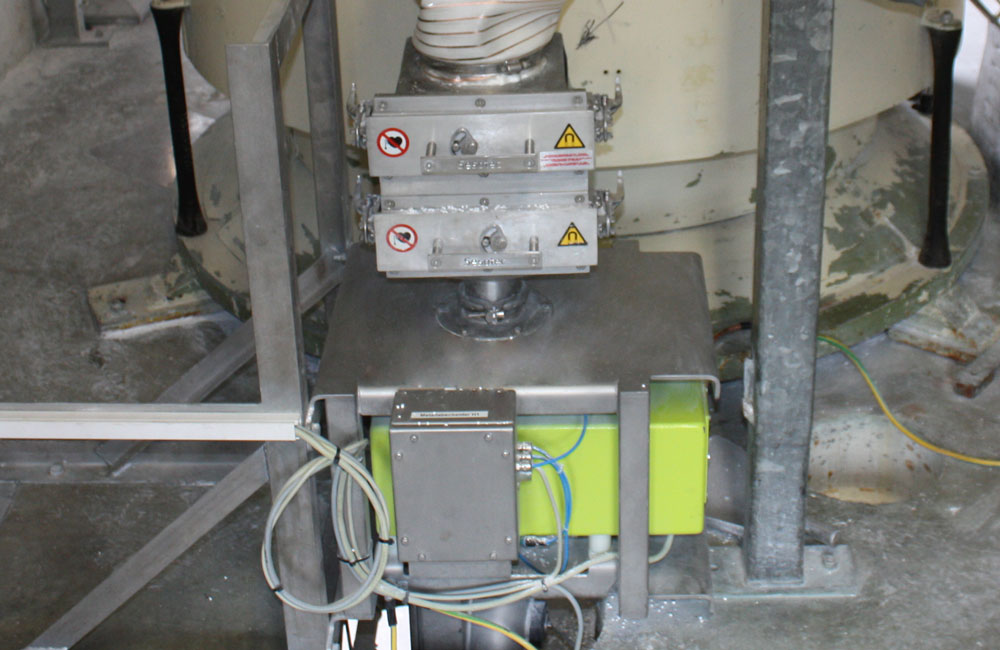

Almi, an Austrian company headquartered near Linz, and one of the

leading manufacturers of quality flavourings and additives for sausage,

meat, ham and fish products, uses Sesotec “Hygienic Design” metal

detectors throughout their entire production process.

Separately purchased recyclate often contains various different polymers as well as metal contaminants such as aluminum, brass, and stainless steel. Learn in our Case Study how Sitraplas has solved this problem.

SITRAPLAS GmbH is a producer of high-performance engineering plastic compounds. Unplanned downtime is a nightmare for every company, but especially for continuous production facilities. When metal separators are networked with plastic processing machines, the flow of information between machines can be monitored.

Pneumatic conveying is common within the milling industry to move large volumes of products. This firm was looking for a metal detection solution to provide enhancements to their food safety initiatives (GFSI) within the challenge of pneumatically conveying the finished product to bulk carriers.

To avoid any metal in the powder, CIPSA wanted to inspect the PVC compounds before they enter the pelletizer. This was to protect the extruder screw from damage and avoid expensive production stops.

The Backwelt Pilz produces pre-baked and pre-cooked deep-frozen baked goods, for the food retail trade, petrol station shops and system gastronomy. In order to ensure that bread and rolls are absolutely free of foreign bodies, the Backwelt Pilz decided, in addition to the existing metal detectors, also to install RAYCON D+ X-ray inspection equipment for packaged products.

When this customer looked for a metal detector, he expected this system to remove metallic contaminations from dry spices inspected in pneumatic pipes without causing any interruptions of the production process.

The quality requirements of the chemical industry are particularly high. Metal detectors play an essential role in the refinement of solids to ensure a consistently high product quality and safety. At the same time, the customers expect quick setup times to achieve high flexibility and efficiency.

Founded in the 1960s, H. Loidl Sausage Producers and Distributors GmbH & Co KG attributes their rapid growth to the high quality of their salami products. Once ripe, some Loidl salami products are packaged in slices. This requires

removing the casing and the aluminum clips by hand. In some cases, residue from the aluminum clips remains on the salami. The standard metal detection solutions Loidl had used up un til that point were not sensitive enough to reliably detect the metal contaminants. So Loidl turned to Sesotec in search of a solution for detecting and automatically rejecting metal contaminants from salami sticks.

For more than 335 years and 14 generations, Rubinmühle has been managed by the Rubin family.

Customers in Europe and beyond benefit from their reliable and flexible supply of innovative, high-quality grain products.

As quality requirements have become

more stringent over time,

Rubinmühle

commenced a search for a solution that could

inspect grain flakes with the best possible detection rates.

Among the favorite products of Tunacor Fishing Ltd are their fish sausages, which are especially celebrated in Spain. However, every now and then they would receive complaints from customers about bits of metal in the sausages.

Many customers face the problem of lacking the knowledge of which setting parameters can cause a significant change in product safety and process relevance. A validation process can aid these customers to overcome this challenge and take a successful path towards compliance with food safety standards. Such as process can also be used as a service.

Milchwerke

Schwaben processes 410 million kilograms of milk and whey each year.

Metal

detection must be installed at various checkpoints to control for the quality

of dairy products. Butter and rice pudding, for example, are transported

through pipelines prior to filling. In

order to ensure these packaged products are free of metallic contaminants,

metal detectors are used.

As a new major company with the highest quality requirements, CREMER needs a powerful and reliable metal detection system to ensure that its production facilities meet international standards and reliably produce safe products. All in the interest of food safety.

As Plastiques ZD grew, it became necessary to find an environmentally friendly and cost-effective solution for recycling defective parts and production waste. The company turned to the long-time Sesotec partner, MAT Technologic, for a solution.

Viet UC faced the challenge of eliminating metallic contaminants from masterbatch to prevent particles from entering plastic mixtures during production. These contaminants could not only compromise the quality of the final product but also lead to machine downtime and customer complaints.

Like in most recycling processes, companies such as World PET Recycling face the challenge of removing contaminants from recycled PET to meet the strict quality standards for food-grade materials.

Brochure about the production and processing of meat products.

Sorting and Detection systems for every stage of the Circular Economy in the plastics industry.

Metal separator for free-fall applications with turnable separation unit

Metall-Separator für Extruder, Spritzgieß- und Blasformmaschinen

Metall-Separator für Spritzgießmaschinen, Extruder und Blasformmaschinen

Metall-Separator für pneumatische Förderleitungen in der Lebensmittelindustrie

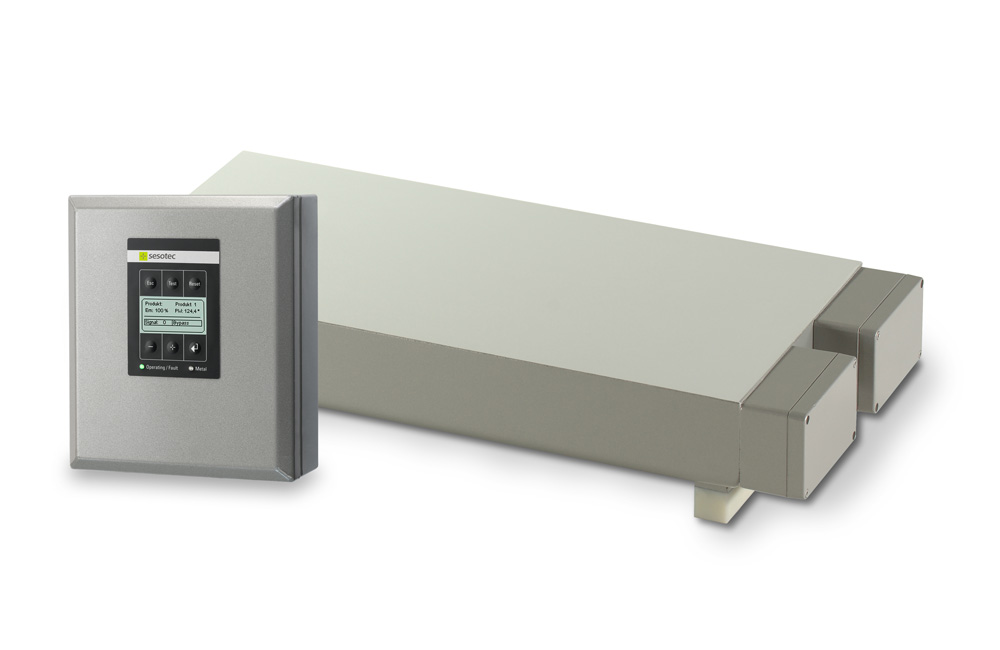

Plate type metal detector for installation in conveyor belts and material chutes

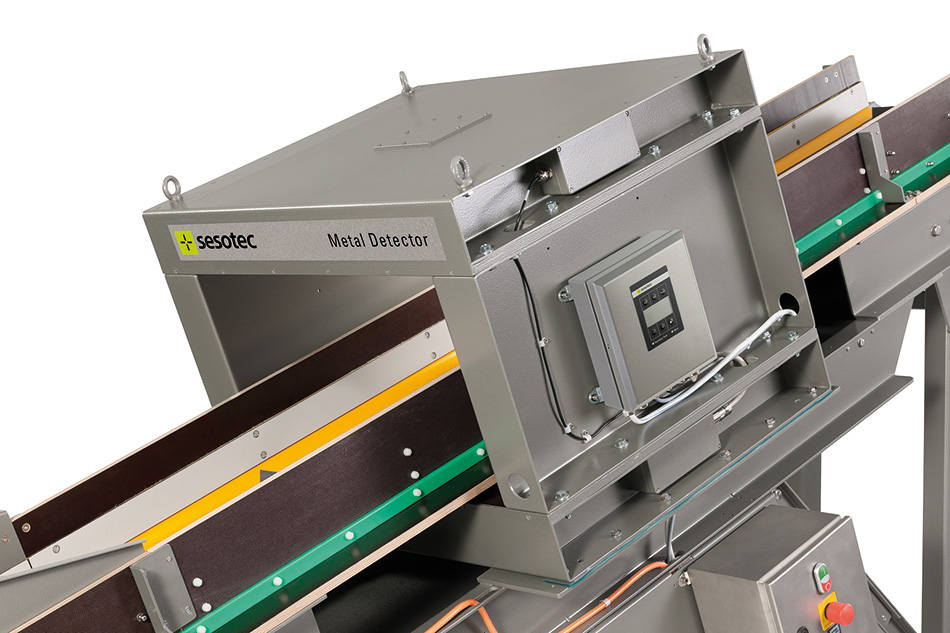

Splitable metal detector for installation on conveyor belts and material chutes

Flächen-Metalldetektor zum Einbau in Förderbänder und Materialrutschen

Kompaktes Metall-Detektionssystem mit Förderband zur Untersuchung von Stückgütern

High-performance metal separator for resin and compound manufacturers