Design

and alternative configurations

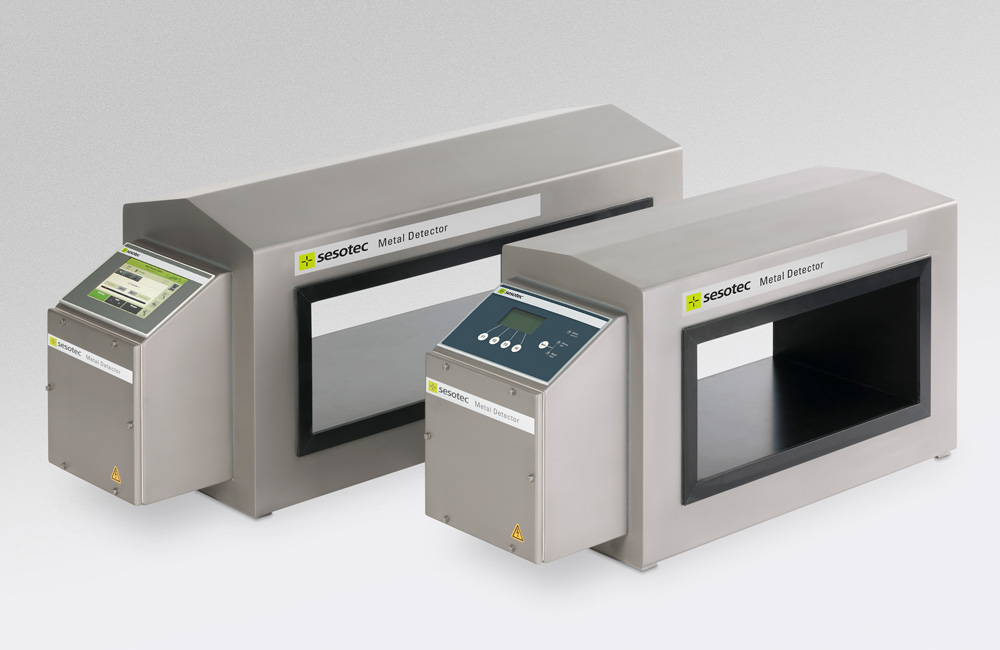

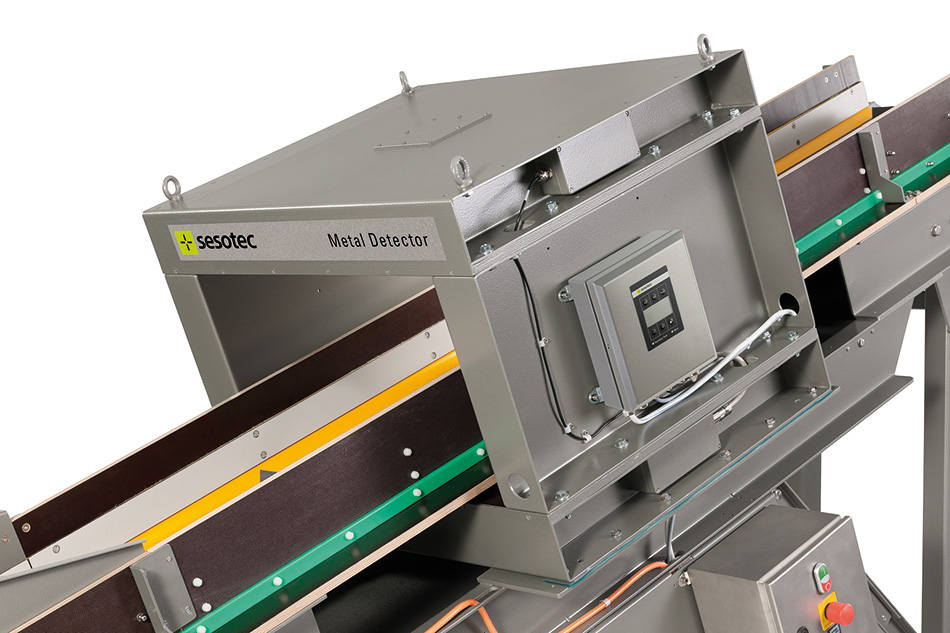

Tunnel metal detectors

enclose the conveyor belt or

material chute, and they are suitable for production heights over 100 mm.

They are available with differently sized apertures.

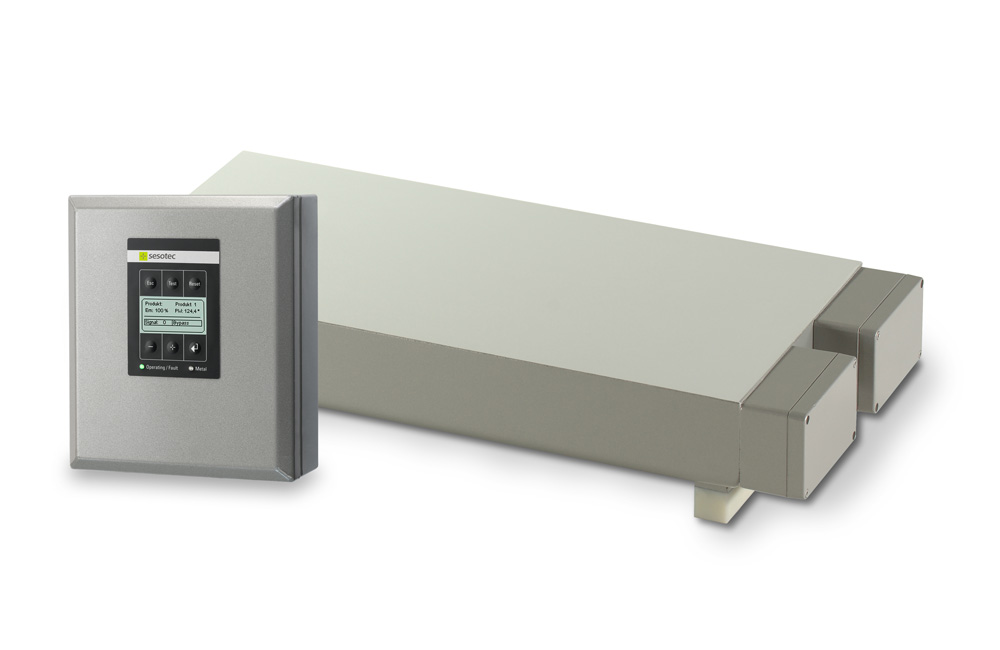

Flat metal detectors

are located under the conveyor

belt and are suitable for flat products up to 100 mm.

Housing/Surface

We

offer the right options for housing and surface finish, even when it comes to

special hygienic requirements and mechanical load.

Metal Detection with

Artificial Intelligence

Products with high or

fluctuating levels of product effect (due, for example, to metallized packaging

or storage in brine or water) can be more reliably inspected with THiNK. False

rejects, and the food waste they cause, are reduced. Learn more about

THiNK.

Products

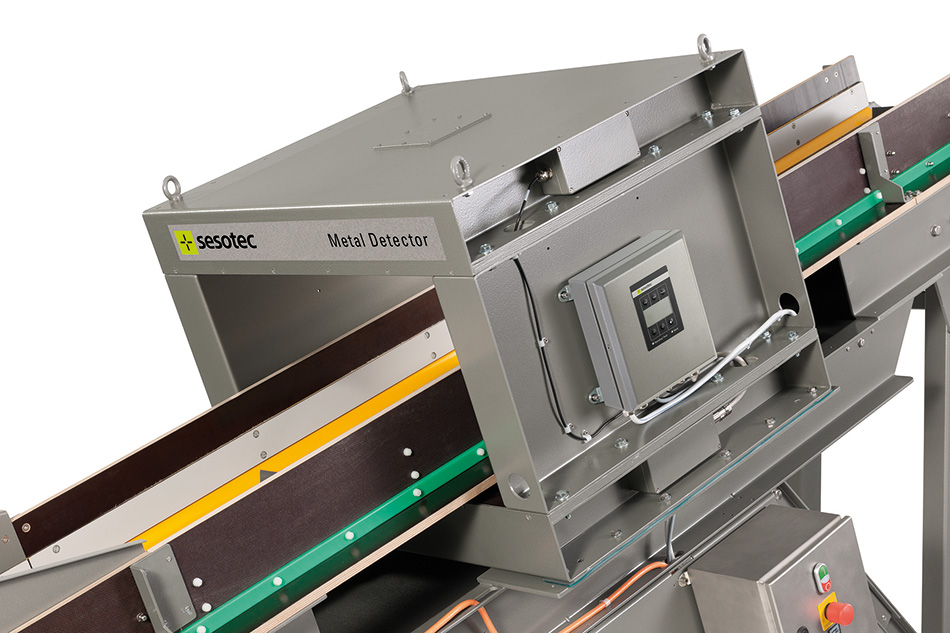

INTUITY

Metal detector for installation in conveyor belt systems - High-End model with multi-simultaneous-frequency technology

Product Brochure

GLS-MF

Metal detector for installation in conveyor belt systems - Standard model with multi-frequency technology

Product Brochure

INSIGHT.HMI Brochure

GLS

Metal detector for installation in conveyor belt systems - Entry model with single/dual-frequency technology

Product Brochure

C-SCAN DLS

Splittable metal detector for installation in conveyor belt systems

Product Brochure

ELCON

Plate-type metal detector with integrated skid plate for installation in conveyor belt systems