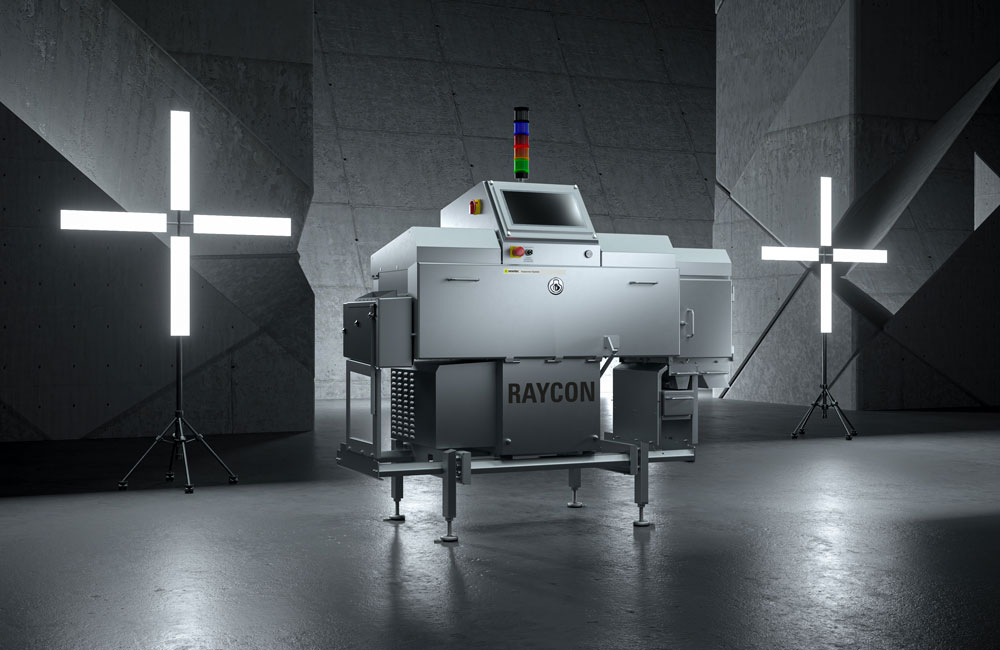

Product quality is the number one priority in the food industry. Manufacturers are liable for contamination, and impurities and quality issues can result in a tarnished reputation. Our X-ray inspection systems detect a wide range of contaminants and product defects, protect you against customer complaints and product recalls − and consumers against harm to their health.

Our portfolio of X-ray inspection systems comprises leading technology in end-of-line detection. If our standard solutions are not the right fit for your needs, we find another way using customization. Our many years of experience in a variety of user-focused industries enable us to quickly immerse ourselves in your processes and offer solutions that will integrate perfectly into your production line!

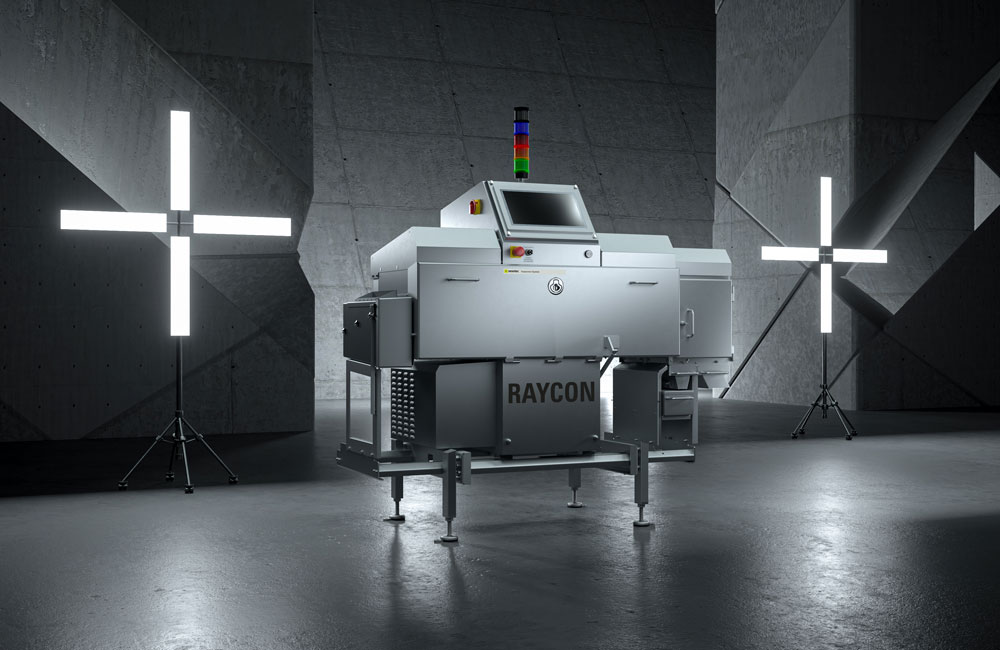

In terms of design and development, we focus on making the installation, operation and cleaning of our X-ray inspection systems as quick and easy as possible. Our machines also feature sturdy construction – quality that is engineered and made in Germany.Looking for more information or advice? Contact us

Unser White Paper beschreibt einige der Herausforderungen, die sich

in der Fleischindustrie hinsichtlich der Produktreinheit und -sicherheit

ergeben und erklärt die verfügbaren Technologien, die für die Detektion

von Fremdkörpern zur Verfügung stehen.

In this White Paper we show you the key benefits and

diverse application possibilities of x-ray technology and how these systems help

you to ensure your product quality.

With our booklet

about X-ray inspection of food products we give you an overview of x-ray

inspection in general, important food standards and Sesotec's

solutions.

In our

e-book we show you, amongst others, what challenges the development of the

world's population and especially food safety pose for manufacturers and

processors and how they can still be mastered.

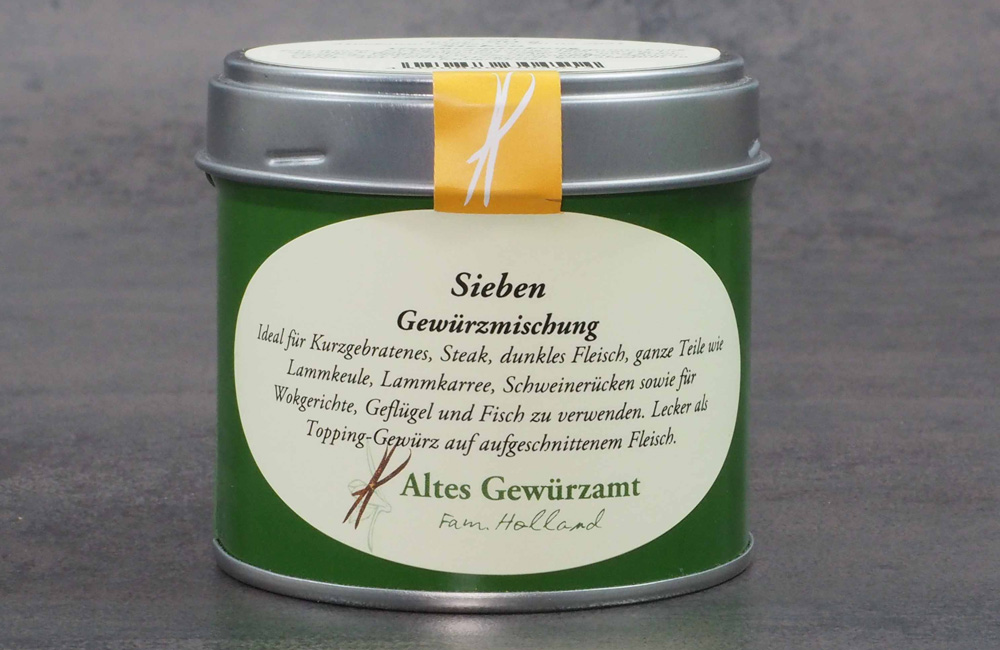

The „Alte Gewürzamt“ produces 120 tons spices and spice mixtures per year on 4.000 square meters. The HACCP analysis revealed an increased risk of contamination with metal, stones and glass. An inspection at the outgoing goods was therefore required to meet the quality standards.

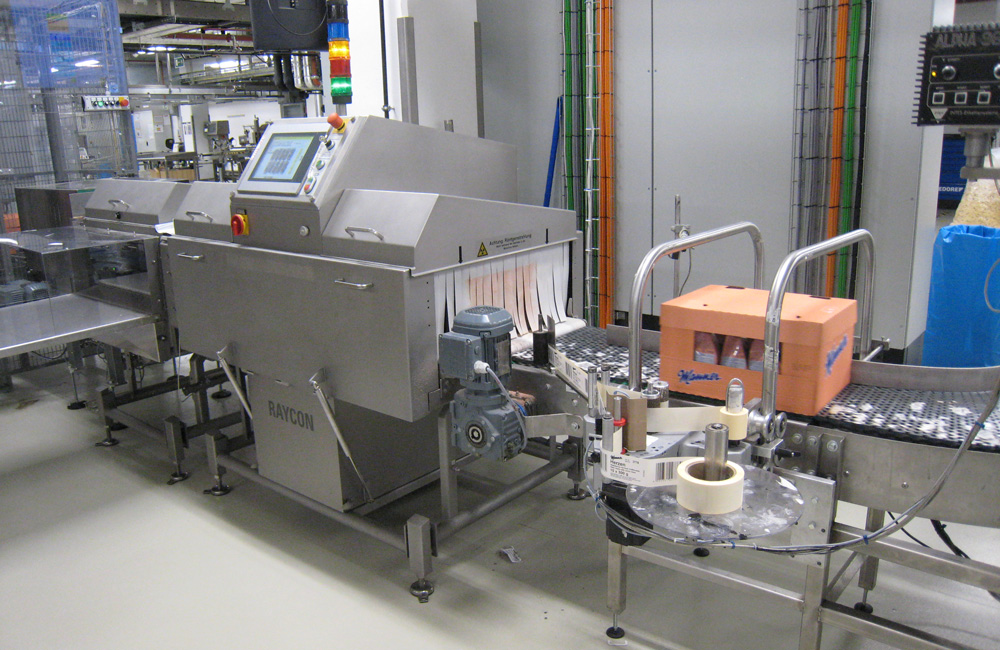

The Backwelt Pilz produces pre-baked and pre-cooked deep-frozen baked goods, for the food retail trade, petrol station shops and system gastronomy. In order to ensure that bread and rolls are absolutely free of foreign bodies, the Backwelt Pilz decided, in addition to the existing metal detectors, also to install RAYCON D+ X-ray inspection equipment for packaged products.

Founded in 1890, the Josef Manner & Comp. AG is the number one specialist for wafers, dragées,

and marshmallow products

in Austria.

As a leading

manufacturer of product

inspection technology, Sesotec supplied Manner with three RAYCON x-ray systems to help them renew their IFS certification in 2019. The solution was a success:

their IFS certificate was renewed and both production

sites continue to operate at the highest level of accreditation.

FF Frischfleisch AG was searching for a way to fully trace 100% of products subject to complaints.

In cooperation with Kundert, the Swiss sales partner, Sesotec was able to develop a solution to this challenge onsite.

EUROVERDE‘s entire product range is the result of a quality process at the highest level. In the field of foreign matter management, EUROVERDE has been using various metal detectors for years to separate metal particles of any kind from the products.

Our client in northern Germany employs around 600 people and produces single and double-sided adhesive tapes on production facilities that are among the most advanced worldwide. Raw materials for adhesive tape production can contain tiny metal particles. Even the smallest foreign object that enters production poses a significant risk.

Brochure about the production and processing of meat products.

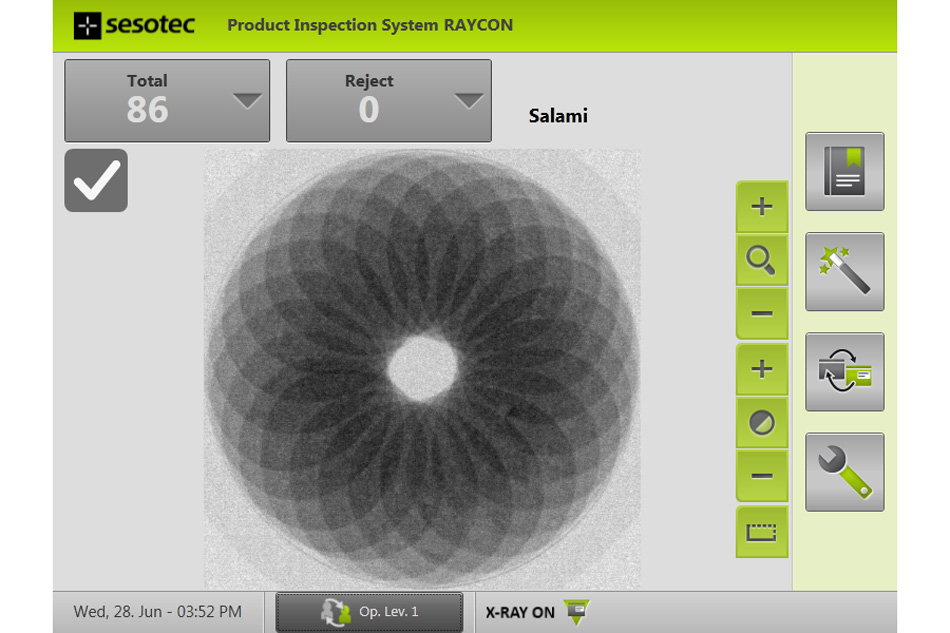

Product inspection system for slim and packaged products at moderate pricing

The RAYCON D+ MX LW is the standard model for inspecting lightly

packaged products. Therefore, this unit is equipped with an innovative

conveyor belt design that does not require curtains.

RAYCON D+ HX LW is the high-end model for inspecting light packaged

products. Therefore, this device is equipped with an innovative conveyor

belt design that does not require curtains. It achieves the highest

detection accuracies.

The RAYCON D+ MX BULK is the standard device for inspecting unpacked

bulk materials. Pneumatically driven flaps ensure minimal loss of good

material.

RAYCON D+ HX BULK is the high-end model for the inspection of unpacked

bulk materials. It achieves the highest detection accuracies.

Pneumatically driven flaps ensure minimal loss of good material.

The RAYCON D+ HX Dual Energy high-end X-ray inspection system detects

difficult-to-detect low-density contaminants such as certain plastics

and cartilage.

Sesotec

has completed the proven RAYCON product family and thus offers X-ray inspection

solutions for all applications in the food industry.