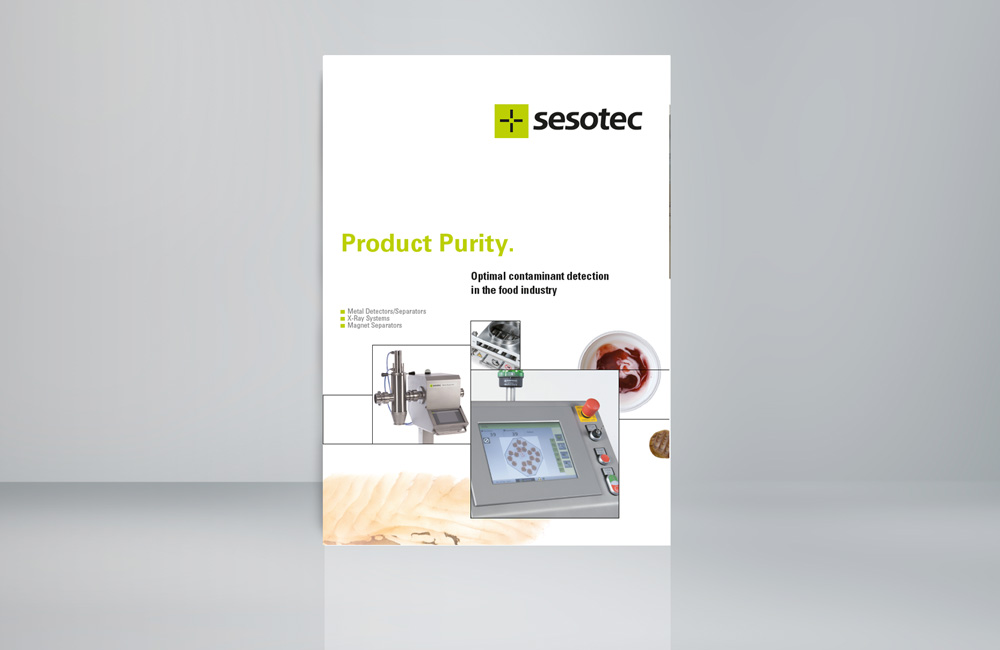

Metal detection systems with integrated belt conveyor

Remove

metallic contaminants – with individual product inspection. Our metal detectors

mounted to conveyor systems provide the ability to detect metallic contaminants

in individual products and remove from the line the contaminated products

quickly and reliably. The most effective protection for your consumers, your

machines and your image.

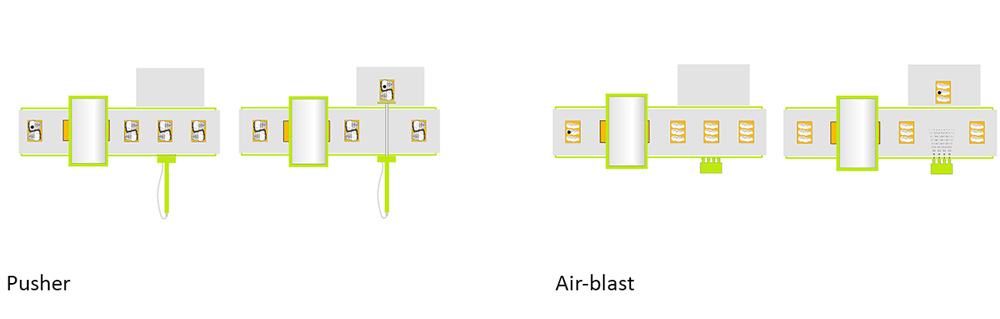

Metal detectors mounted to belt conveyors are an

all-in-one system consisting of a metal detector, a conveyor belt and an optional

reject system. They can be easily integrated into existing production lines.

Our metal detector conveyor systems are designed to be robust and incorporate hygienic

conveyor designs. The modular design allows for custom solutions designed to

your specific product and production line.

More information on the operations of a Sesotec

metal detectors is available

here.