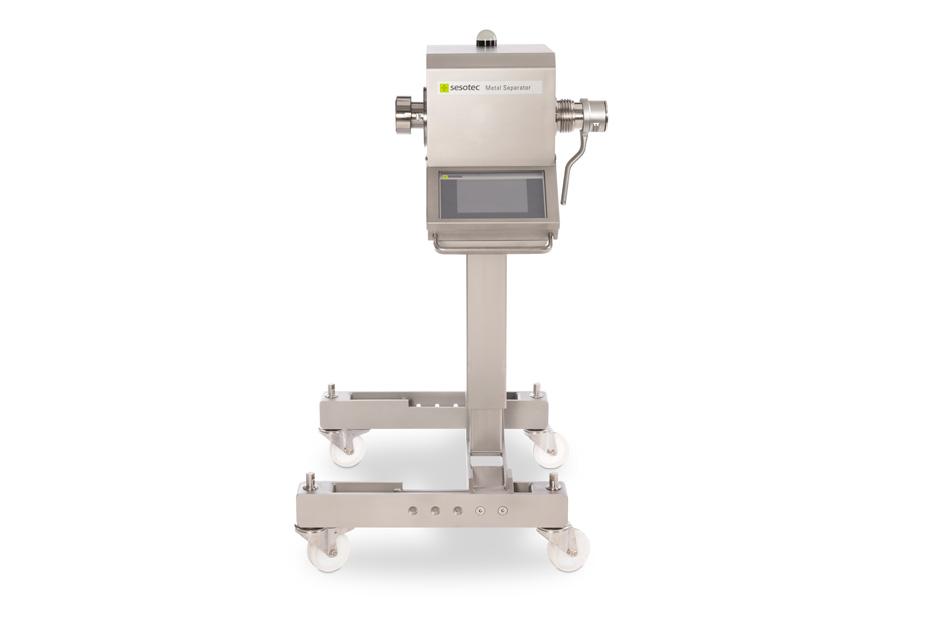

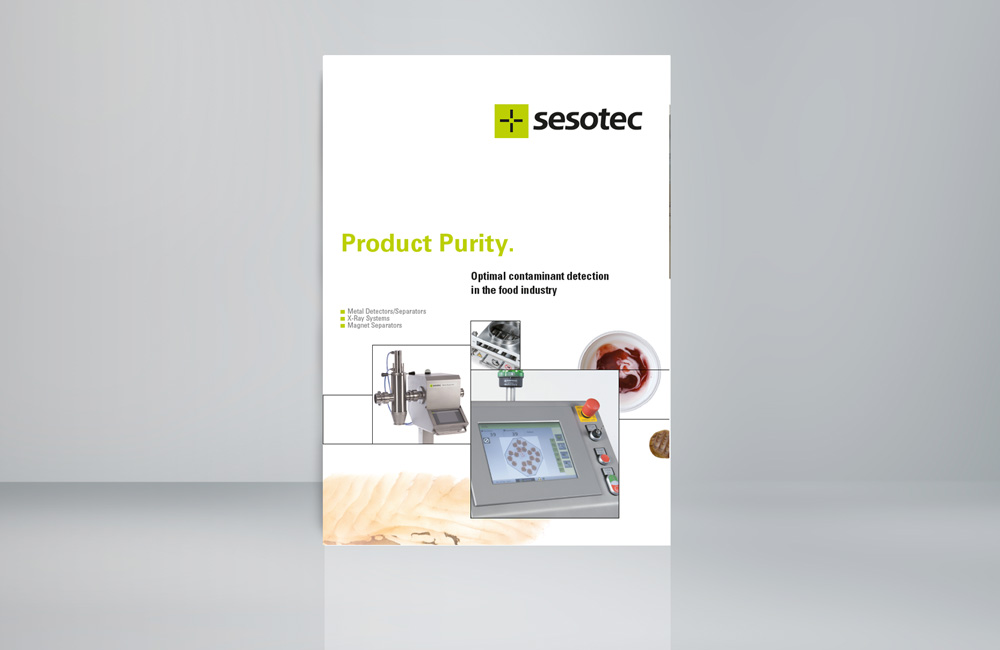

Metal detection systems for liquids and pastes

The food industry has to meet the highest quality standards. Regardless of whether you produce sausage meat, processed cheese, jam, mustard or soups, our metal detectors will help you to reliably protect machines and consumers from metallic contaminants. What is more, they are extremely easy to integrate into your production lines.

Our metal detection systems for liquid and paste

products can be quickly and easily integrated into existing piping systems and

connected to all common vacuum fillers, pumps, clipper machines and

sausage-filling machines. Thanks to the different separation systems to choose

from, they ensure the safe and efficient removal of all metallic contaminants. More

information on how Sesotec metal detectors and separators work is available

here.