Design and alternative configurations

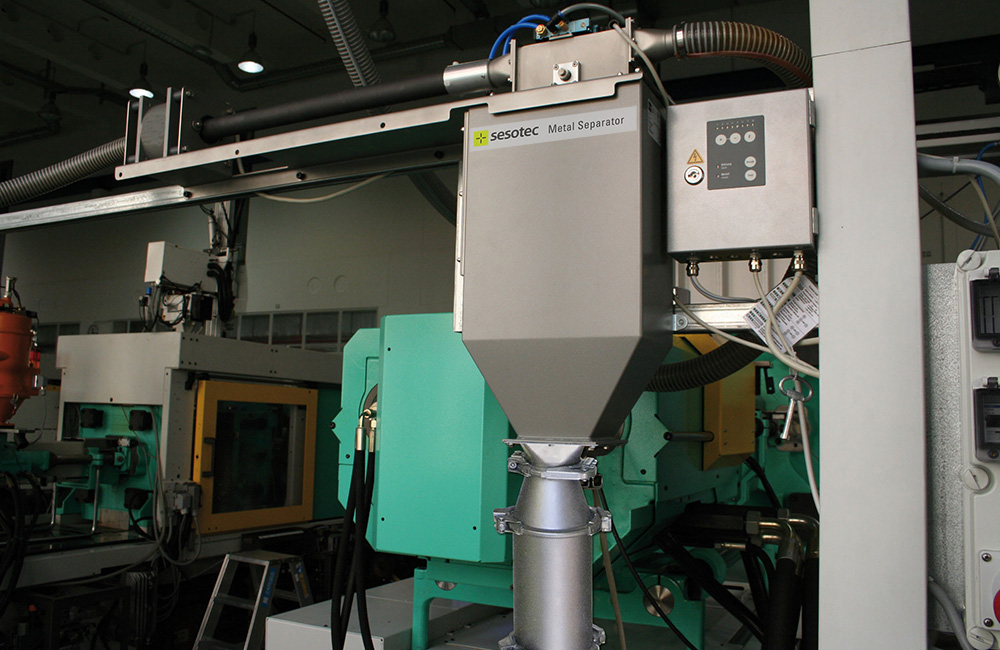

Simple and easy assembly

All components come pre-assembled, and the assembly

frame ensures quick and easy installation. A compact design also helps you to save

space.

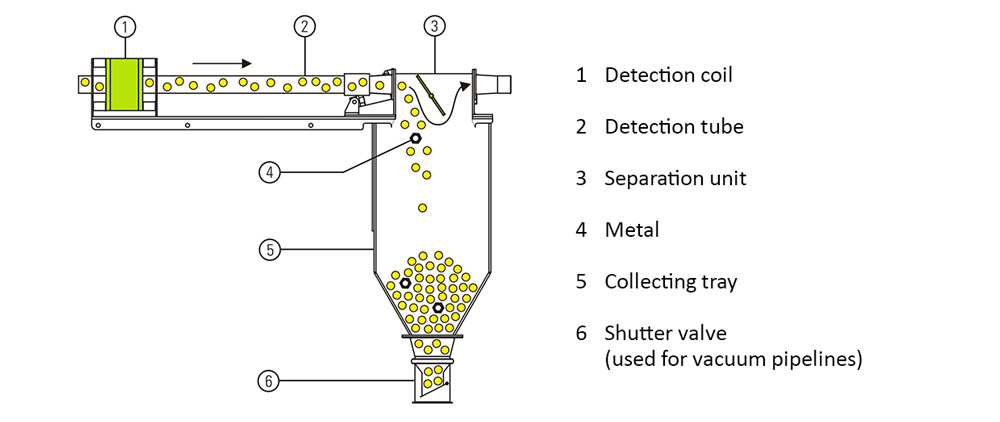

Separation system

Thanks to its responsive shutter flap, the “Quick-Flap” separation unit

safely removes metal particles even at high conveying speeds without

interrupting the flow of the conveyed material. It also prevents leak air from

entering the conveyor pipes. The entire

separation mechanics, junctions and separation flap are made out of stainless

steel (1.4301).

Different pipe diameters

Integration into already existing conveyor pipe systems with standard

nominal widths up to 150 mm is possible without any issue thanks to

quick-lock couplings and ventilation flanges.

Products

GF

Metal separator for pneumatic conveyor pipes

Product Brochure

GF 4000

Metal separator for pneumatic conveyor pipes with high hygienic requirements

Product Brochure