Purity is value

Purity is value

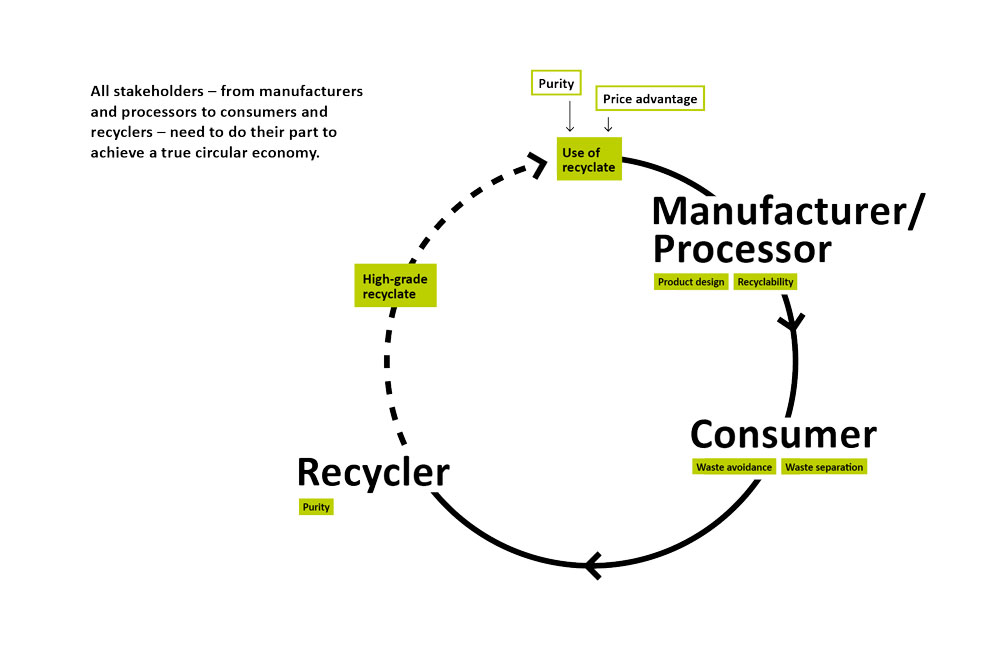

A circular economy must not only be sustainable and environmentally friendly, but also profitable for the companies that manufacture, process, and recycle plastics. To this end, the purity of the raw materials and sorting streams plays a decisive role.

Using intelligent technologies and services, we help businesses in the plastics sector operate with circularity and efficiency. In this way, profitability, sustainability, and environmental protection go hand in hand.

The plastics industry is under pressure. Between climate change, the depletion of finite resources, and the vast amounts of plastic waste floating in the world’s oceans, the perception of plastic is changing among politicians, businesses, and consumers alike. Establishing a circular economy promises numerous opportunities for manufactures, processors, and recyclers of plastics; but it would also come with a variety of challenges.

From processors and manufacturers, to consumers, to recyclers: to establish an enduring circular economy, all actors must see a benefit.

The availability, quality, and price of raw materials play a significant role in the profitability of plastics manufacturing and processing. The same also applies to the recycling industry, where fluctuations in the price of recyclate and virgin material pose additional challenges.

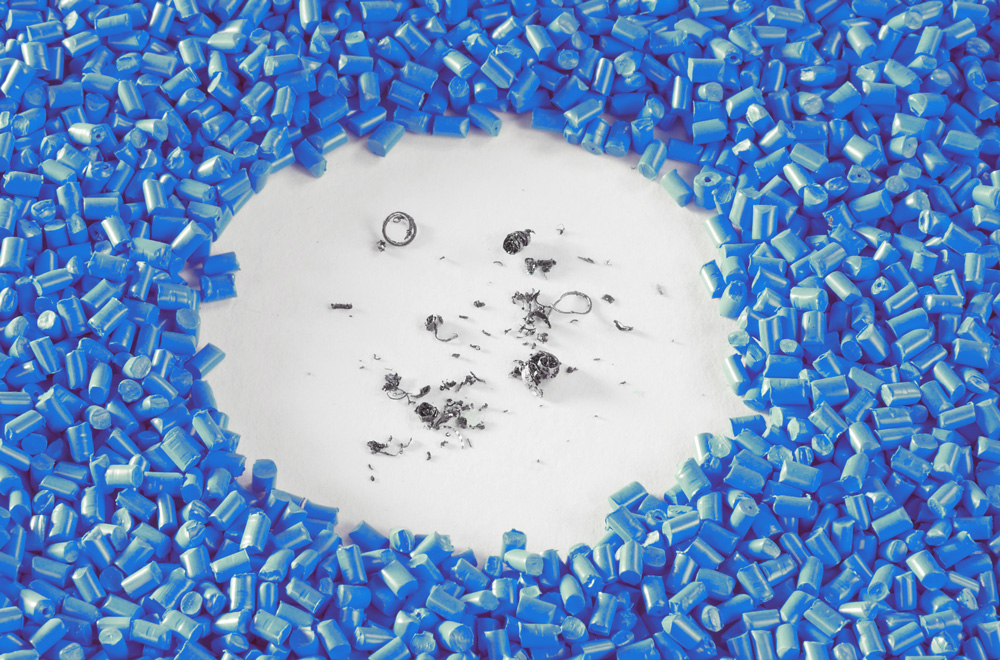

For businesses that manufacture, process, or recycle plastics, flexible technology is key to achieving optimum profitability. Facilities outfitted with a coordinated, sophisticated system of metal separators and sorting equipment are positioned for higher system availability and processing efficiency.Like recyclers, manufacturers and processors of plastics must contend with fluctuations in the availability of recycled materials. This is especially true in times of high demand. Furthermore, not all recycled materials are of high enough quality or available in sufficient quantities to be suitable for further processing. The higher the quality of the recycled material, the more efficient its processing.

The plastics, rubber and chemical industries often use expensive equipment, such as injection-moulding machines, calender rolls, extruders and blow-moulding machines. The continuous operation of these machines is tremendously important to a company’s profitability. However, operations can come to a standstill if even the tiniest pieces of metal become lodged in melt filters, hot runners or nozzle tools, obstruct check valves or cause damage to plasticising screws or cylinders. Metal detectors and magnet separators can prevent equipment failure from occurring. The timely detection and removal of contaminants increases process continuity and productivity by reducing downtime.

Our portfolio of modular products is compatible with all specifications required in diverse manufacturing and processing applications. We have standardized solutions for all process steps:

How easy is it to install the metal detector in the production line – and

how easy is it for your staff to operate the device?

In our white paper, we provide a detailed

outline of the issues, their causes and the necessary countermeasures for

eliminating metal contamination in the plastics processing industry.

The Whitepaper explores the challenges that

metal contamination poses to compounding and masterbatch production and

considers the key features that metal separators must have to provide an

adequate solution.

The plastics industry is under pressure. Between climate change, excessive consumption of finite resources, and vast amounts of plastic waste in the world’s oceans, plastics are coming to be seen in a different light by politicians, businesses, and consumers alike. Read in our e-book about the most important factors of a functioning circular economy, especially which challenges and opportunities exist for recyclers and plastics processors.

In the new Sesotec White Paper "Using recycled materials in plastics processing" you will learn about

Separately purchased recyclate often contains various different polymers as well as metal contaminants such as aluminum, brass, and stainless steel. Learn in our Case Study how Sitraplas has solved this problem.

SITRAPLAS GmbH is a producer of high-performance engineering plastic compounds. Unplanned downtime is a nightmare for every company, but especially for continuous production facilities. When metal separators are networked with plastic processing machines, the flow of information between machines can be monitored.

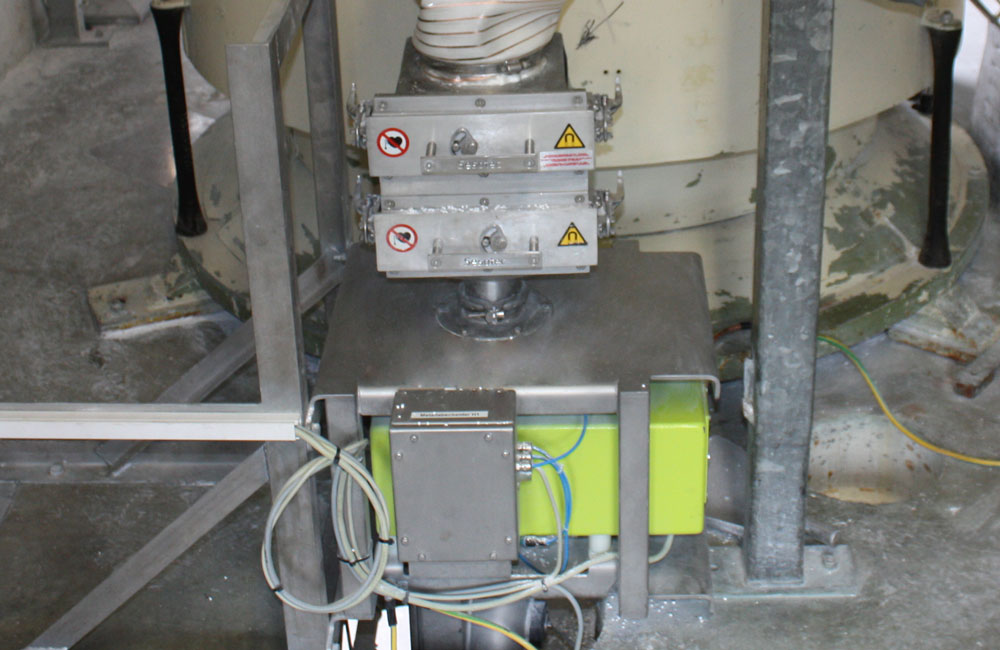

To avoid any metal in the powder, CIPSA wanted to inspect the PVC compounds before they enter the pelletizer. This was to protect the extruder screw from damage and avoid expensive production stops.

The quality requirements of the chemical industry are particularly high. Metal detectors play an essential role in the refinement of solids to ensure a consistently high product quality and safety. At the same time, the customers expect quick setup times to achieve high flexibility and efficiency.

Our client in northern Germany employs around 600 people and produces single and double-sided adhesive tapes on production facilities that are among the most advanced worldwide. Raw materials for adhesive tape production can contain tiny metal particles. Even the smallest foreign object that enters production poses a significant risk.

As Plastiques ZD grew, it became necessary to find an environmentally friendly and cost-effective solution for recycling defective parts and production waste. The company turned to the long-time Sesotec partner, MAT Technologic, for a solution.

Viet UC faced the challenge of eliminating metallic contaminants from masterbatch to prevent particles from entering plastic mixtures during production. These contaminants could not only compromise the quality of the final product but also lead to machine downtime and customer complaints.

Sorting and Detection systems for every stage of the Circular Economy in the plastics industry.

The brochure highlights

the entire Sesotec product portfolio, which is specially tailored to the needs

of the plastics industry.

Metal separator for free-fall applications with turnable separation unit

Metall-Separator für Extruder, Spritzgieß- und Blasformmaschinen

Metall-Separator für Spritzgießmaschinen, Extruder und Blasformmaschinen

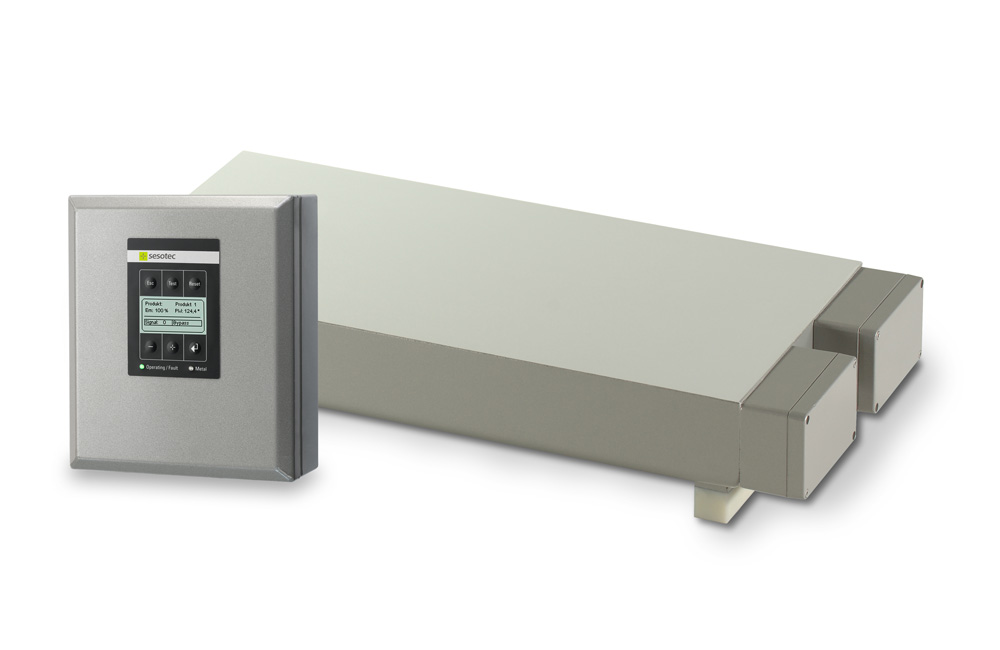

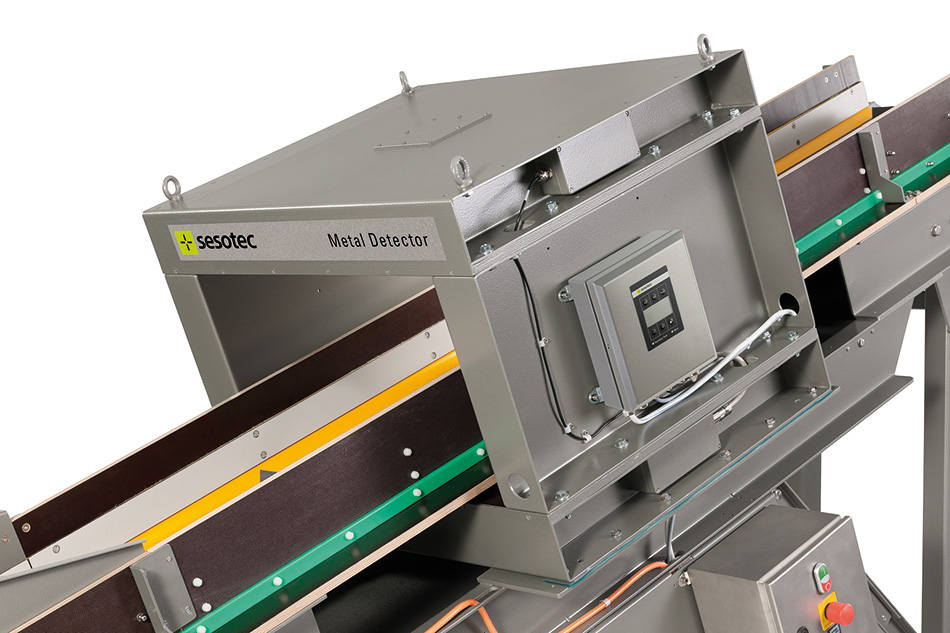

Plate type metal detector for installation in conveyor belts and material chutes

Splitable metal detector for installation on conveyor belts and material chutes

Flächen-Metalldetektor zum Einbau in Förderbänder und Materialrutschen

Kompaktes Metall-Detektionssystem mit Förderband zur Untersuchung von Stückgütern

Rohr-Magnet für Spritzgießmaschinen, Extruder und Blasformmaschinen

Rohr-Magnet für Spritzgießmaschinen, Extruder und Blasformmaschinen

High-performance metal separator for resin and compound manufacturers

Looking for more information or advice? Contact us