Thank You for an Amazing K-Messe

Economy meets Ecology

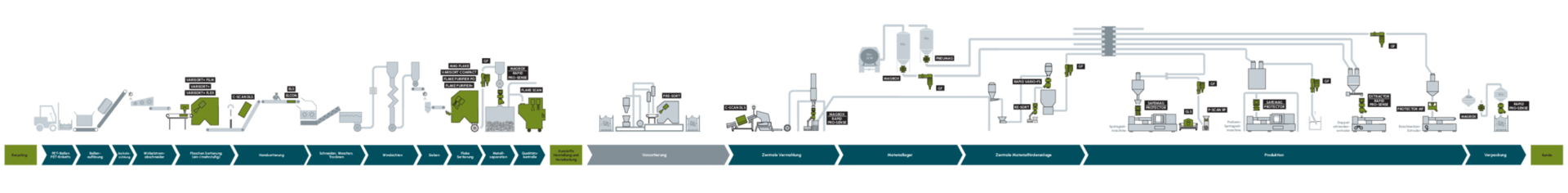

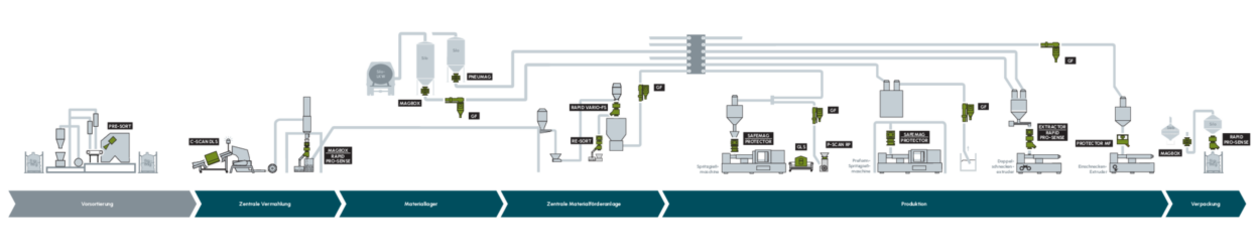

Climate protection, circular economy, and digitalization – three megatrends that Sesotec transforms into tangible solutions. At K 2025, we demonstrated how efficiency and sustainability are already becoming a reality in the plastics value chain.

Now, after an intense and inspiring week at the trade fair, we want to share the highlights and key moments with you – insights, encounters, and innovations that further pave the way for a sustainable plastics industry.

Sesotec Moments at K 2025

Impressions

Media Engagement

At the K-Messe 2025, our booth became a hub for numerous media representatives. We seized the opportunity to showcase our latest innovations and discuss current industry trends. A huge THANK YOU to all the journalists for visiting and showing great interest in our breakthroughs.

ZDF also made a point to stop by the Sesotec booth, capturing video segments of our solutions for the Circular Economy. You can watch the full coverage of the event in the ZDF media library.

.JPG)

.JPG)

.JPG)

.jpg)

.JPG)

If ever there was a time in history when we could change our global economy, it's right now.

Our Highlights from K 2025

NEXT LEVEL AI

SUSTAiN Technologies

Where high-tech sensors fall short, our AI solutions empower you to reliably detect and differentiate nearly any material.

INNOVATIONS

Maximize Profits with Flake Sorting

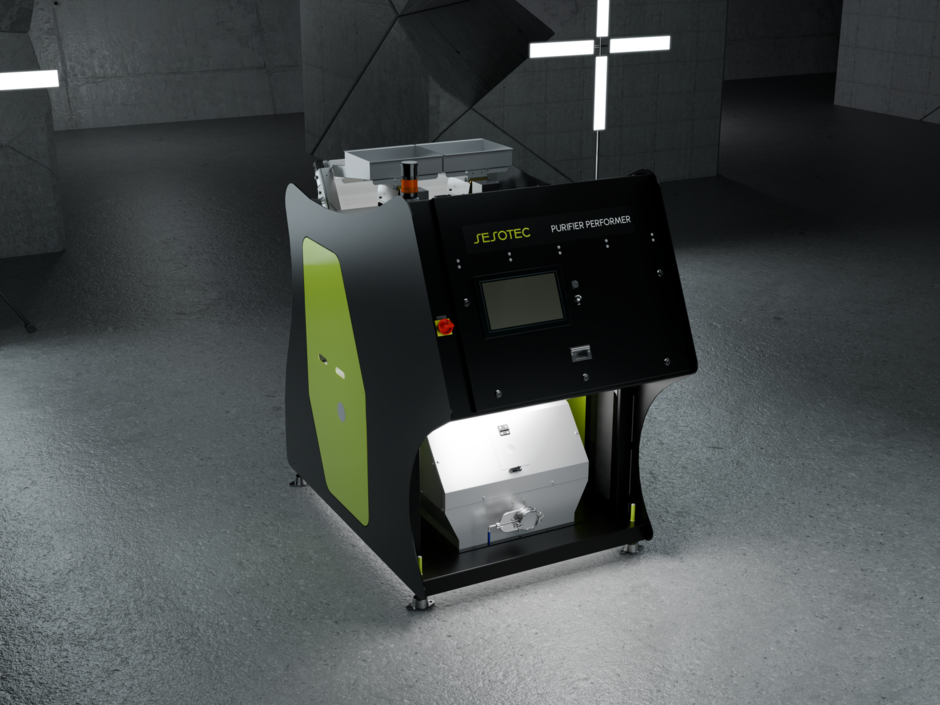

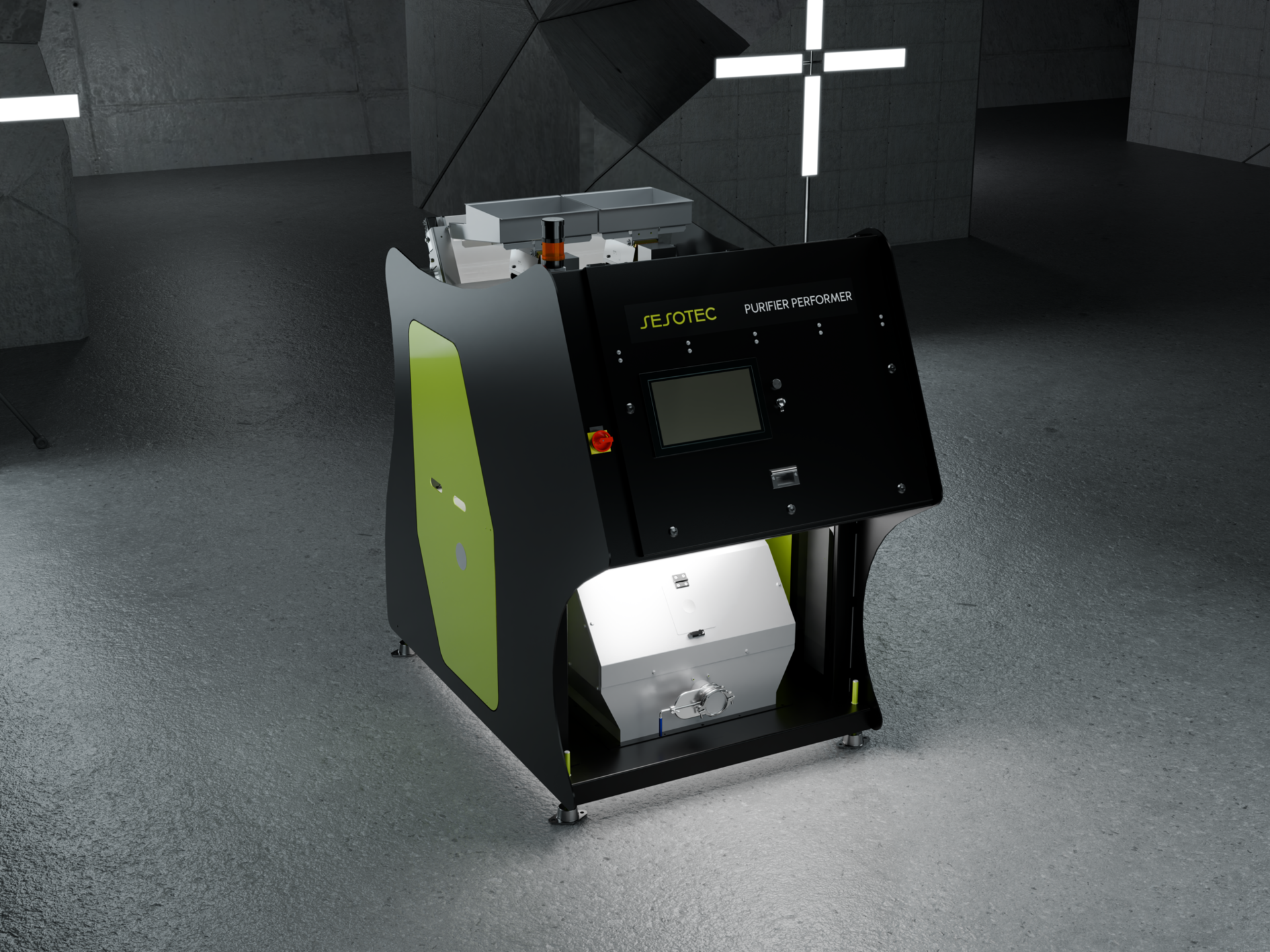

Our new PURIFIER PERFORMER sorting system for plastic flakes sets new standards in efficiency and precision

Maximize Profits with Comprehensive Flake Sorting

The New PURIFIER PERFORMER

Our new PURIFIER PERFORMER sorting system for plastic flakes sets the standard in efficiency and precision:

With dual-sided inspection, even opaque materials, labels, prints, or attachments are reliably detected. The enhanced C- & NIR resolution identifies the smallest impurities, ensuring minimal loss and maximum purity. Offering customizable sensor combinations (C, N), working widths from 768mm to 3072mm, and throughput rates from 2.3 to 9.0 t/h, the system delivers unparalleled flexibility for diverse applications.

Instant Flake Analysis with FLAKE SCAN

High material quality is a crucial profitability factor for manufacturers and processors of plastics. Our FLAKE SCAN analysis system is specifically designed for use in plastic recycling and processing, enabling quick and reliable spot checks by plastic type, color, and foreign bodies.

In addition to qualitative material data, FLAKE SCAN also provides granulometric insights into particle size distribution—essential for targeted process optimization in recycling.

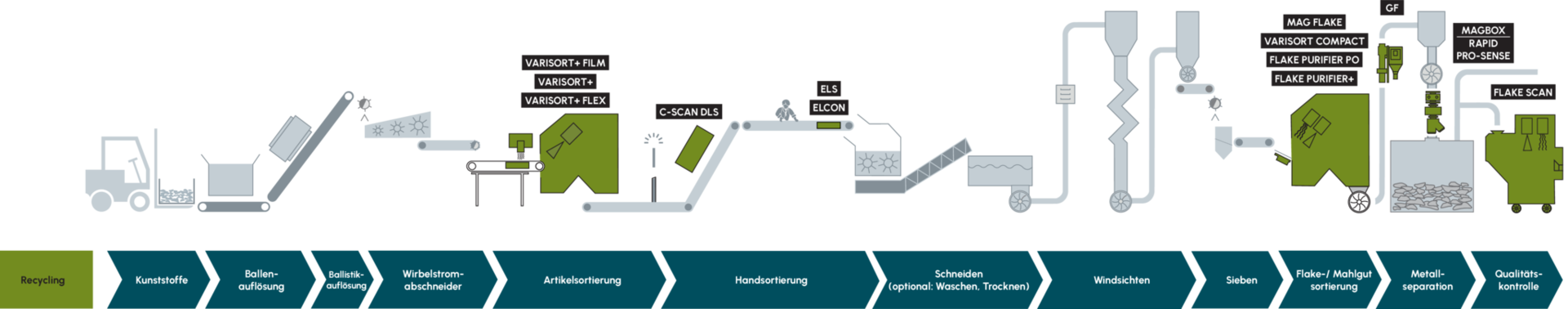

Recycling

Our Highlights in Plastic Recycling

Plastics Processing

Our Highlights for Plastic Processing

Efficiency and Security

Highlights for Plastics Processors

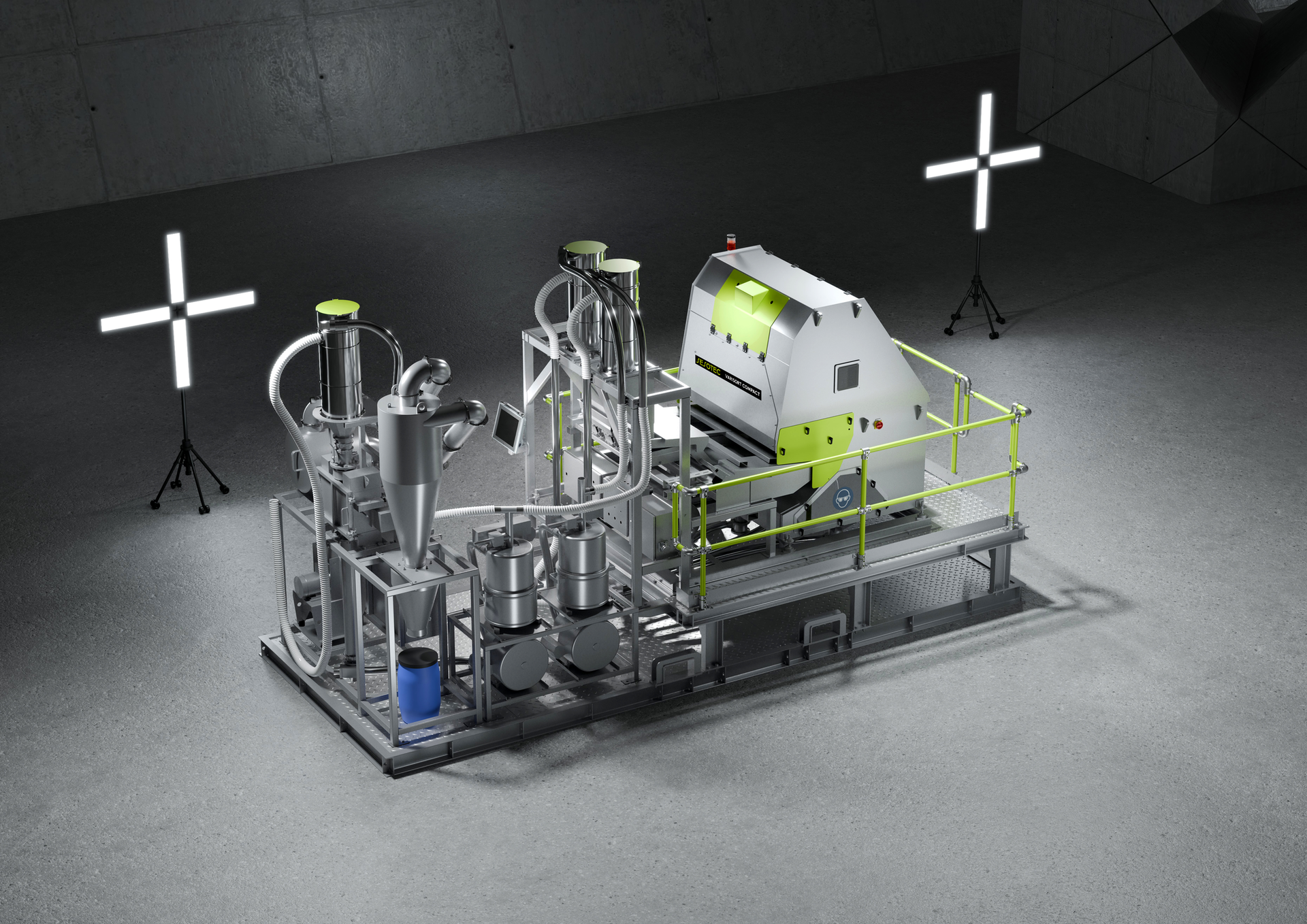

Live at K 2025

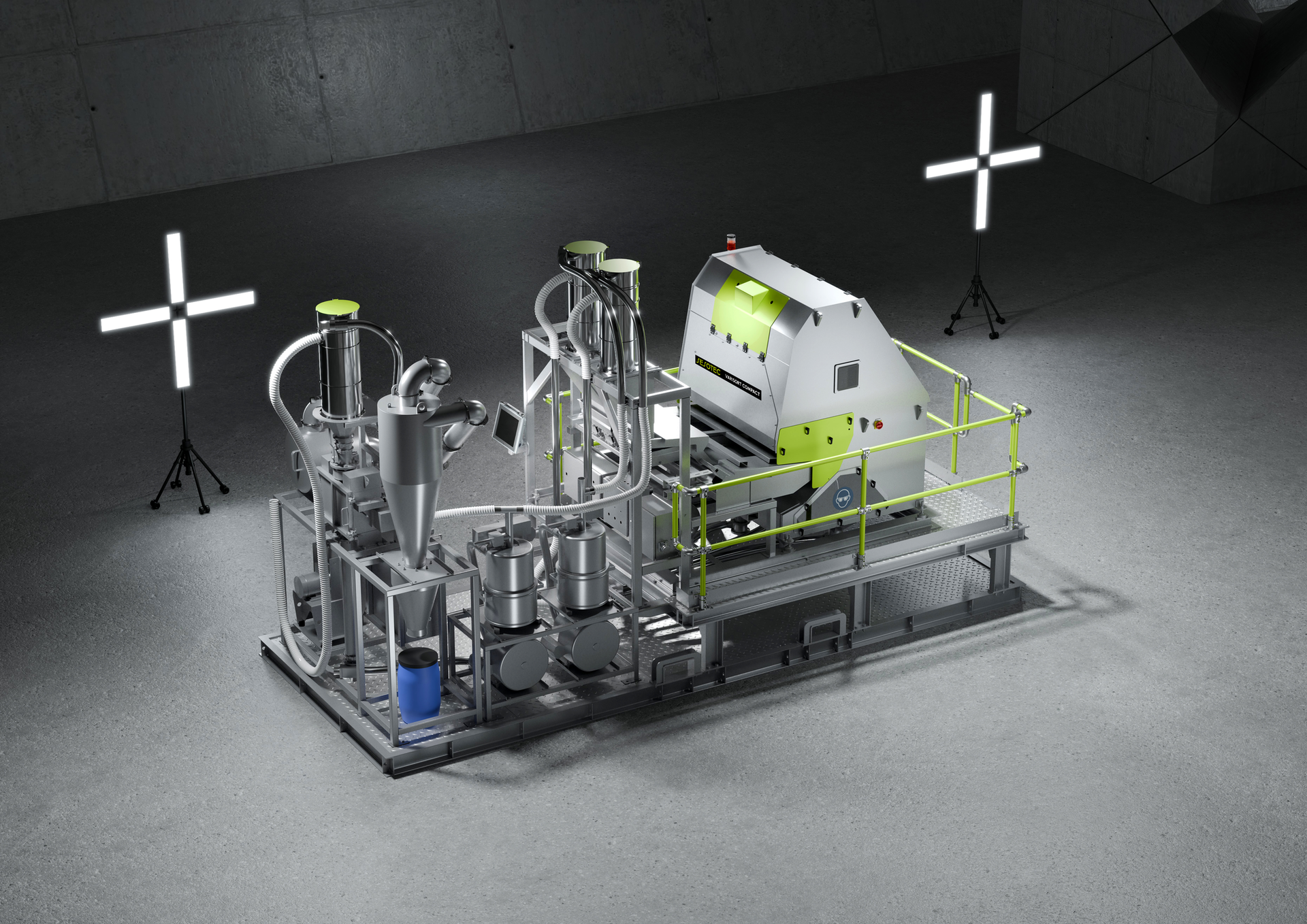

At PRE-SORT, the VARISORT COMPACT sorting device, dedusting, material conveying, and central control are all integrated into one platform. Plastic regrind is sorted by color, shape, metal type, or plastic type according to the production line's needs. This makes PRE-SORT an effective solution for regrind sorting. Its mobility is unmatched. Built on a mobile base, PRE-SORT can be deployed wherever the platform is needed.

Even the tiniest metal particles in plastic melt can cause costly disruptions in injection molding, extrusion, and blow molding. As the use of regrind and recycled materials increases, so does the presence of these metal contaminants. Clogged nozzles, filters, and hot runner systems frequently result in production downtime, delays, and missed delivery deadlines. The GF Metal Separator is used in suction or pressure conveyor lines to protect injection molds and processing machinery.

The RAPID VARIO-FS metal separator is designed for inspecting bulk materials in free-fall conveyor lines. Its separate detection and separation units allow the reject outlet to be rotated to align with the collection container.

Companies transforming recyclate into new granulate rely on the FLAKE SCAN material analysis system for incoming goods inspection. In the recycling sector, quality labs use the device for outgoing goods control. Traditionally, these analyses are manual, time-consuming, and yield non-reproducible results. With FLAKE SCAN, you can generate reports on plastic composition and color discrepancies in just minutes, ensuring consistent high quality and reproducible outcomes.

The PROTECTOR metal separator is installed directly above the material feed of an injection molding machine, extruder, or blow molding machine. It detects all magnetic and non-magnetic metal contaminants (steel, stainless steel, aluminum, ...) – even if they are embedded within the product. Metal contaminants are removed via the separating unit (Quick-Valve).

Monitoring Package

The Monitoring Package's sensor suite ensures optimal ejection rates for applications involving standing material columns in extrusion, injection molding, or blow molding processes. Anomalies are reliably detected, elevating plastic processing to new heights in machine protection and product quality.

Speed Measurement

The airflow speed within the closed pipe system is known. But how can you accurately measure the actual product speed to optimize the production process and minimize the incorrect ejection of good material? It's simple with the innovative sensors and data analysis of GF.

Profitable Sorting

Highlights for Plastic Recyclers

Live at K 2025

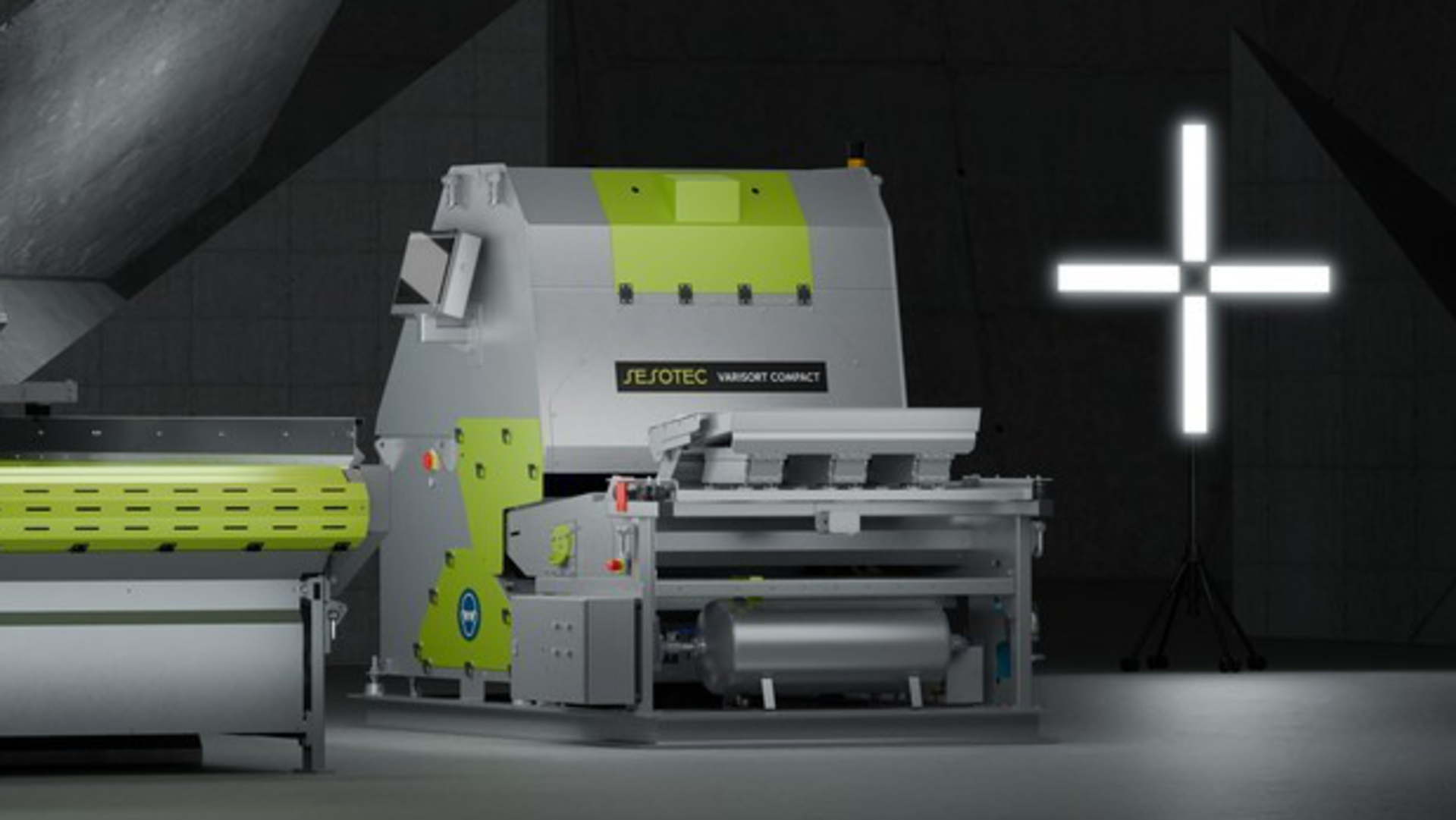

VARISORT COMPACT sorting systems offer a sleek, space-saving design that outperforms traditional belt sorters with unmatched mobility. Equipped with an inductive metal sensor, they efficiently detect and separate all types of metals. The color and shape sensor distinguishes between different colored metals and sorts by color and shape for a wide range of materials from 5 to 50 mm. The near-infrared sensor expertly separates various types of plastics.

Companies transforming recyclate into new granules rely on the FLAKE SCAN material analysis system for efficient incoming goods inspection. In the recycling sector, quality labs use the device for outgoing goods control. Traditionally, these analyses are manual, time-consuming, and lack reproducibility. With FLAKE SCAN, generate detailed reports on plastic composition and color discrepancies in just minutes, ensuring consistent high quality and reproducible results.

At PRE-SORT, the VARISORT COMPACT sorter, dedusting, material handling, and central control are seamlessly integrated into one platform. Plastic granulates are sorted by color, shape, metal type, or plastic type, tailored to your production line's needs. PRE-SORT offers an efficient solution for granulate sorting. Its standout feature? Mobility. Built on a mobile base, PRE-SORT can be deployed wherever the platform is needed.

The PURIFIER PERFORMER revolutionizes plastic flake sorting with dual-sided inspection, high-resolution C- and NIR technology, customizable sensors, and adaptable working widths, delivering unmatched purity, efficiency, and versatility.

Material Sorting with Artificial Intelligence

SUSTAiN Technologies

NIR-Ai

For precise differentiation, the point clouds defined by the near-infrared sensor's spectral analysis must be distinctly separate. When significant overlaps, as shown in the image on the left, occur, the risk of misidentification increases. Valuable resources for recycling are lost. A typical challenge for NIR sensors: Monolayer and Multilayer PET.

OBJECT-Ai

Harnessing the power of Artificial Intelligence, our Color Sensor assigns specific attributes to each object through color and shape analysis. This ensures precise classification and differentiation of quality materials from defects based on shape, color, and texture (bounding boxes).

Thank you for an unforgettable K 2025. See you in 2028.

The next K-Messe will take place from October 18-25, 2028, in Düsseldorf.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)