Sesotec GmbH, a leading manufacturer of foreign object detection, sorting, and analysis systems, will also be represented at the FAKUMA trade fair in Friedrichshafen from October 15 to 19. Under the motto "Economy meets Ecology," Sesotec shows how intelligent technologies and sustainable business go hand in hand. Visitors have the opportunity to discover Sesotec's latest developments and services in Hall B1, Stand 1301 & 1302.

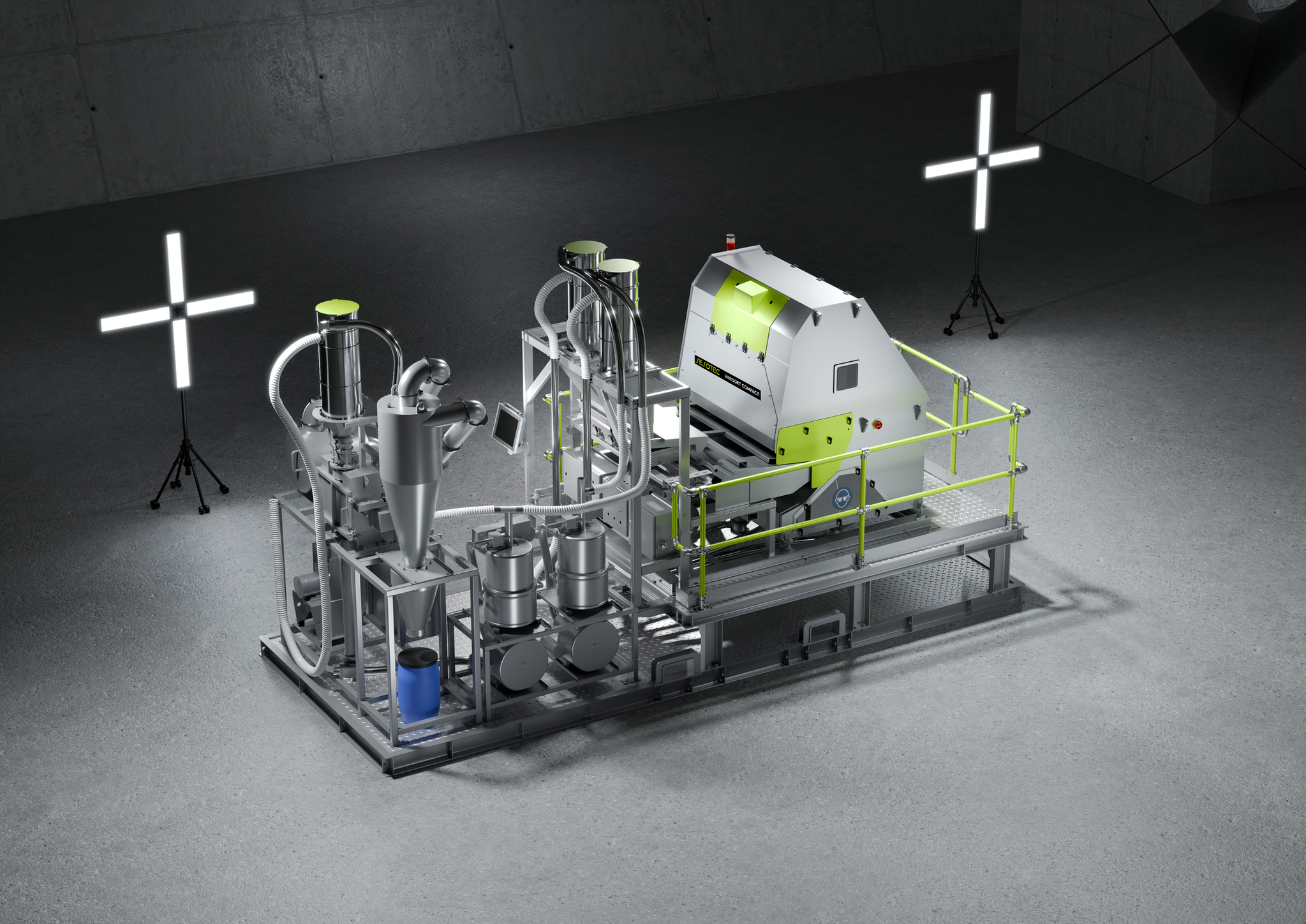

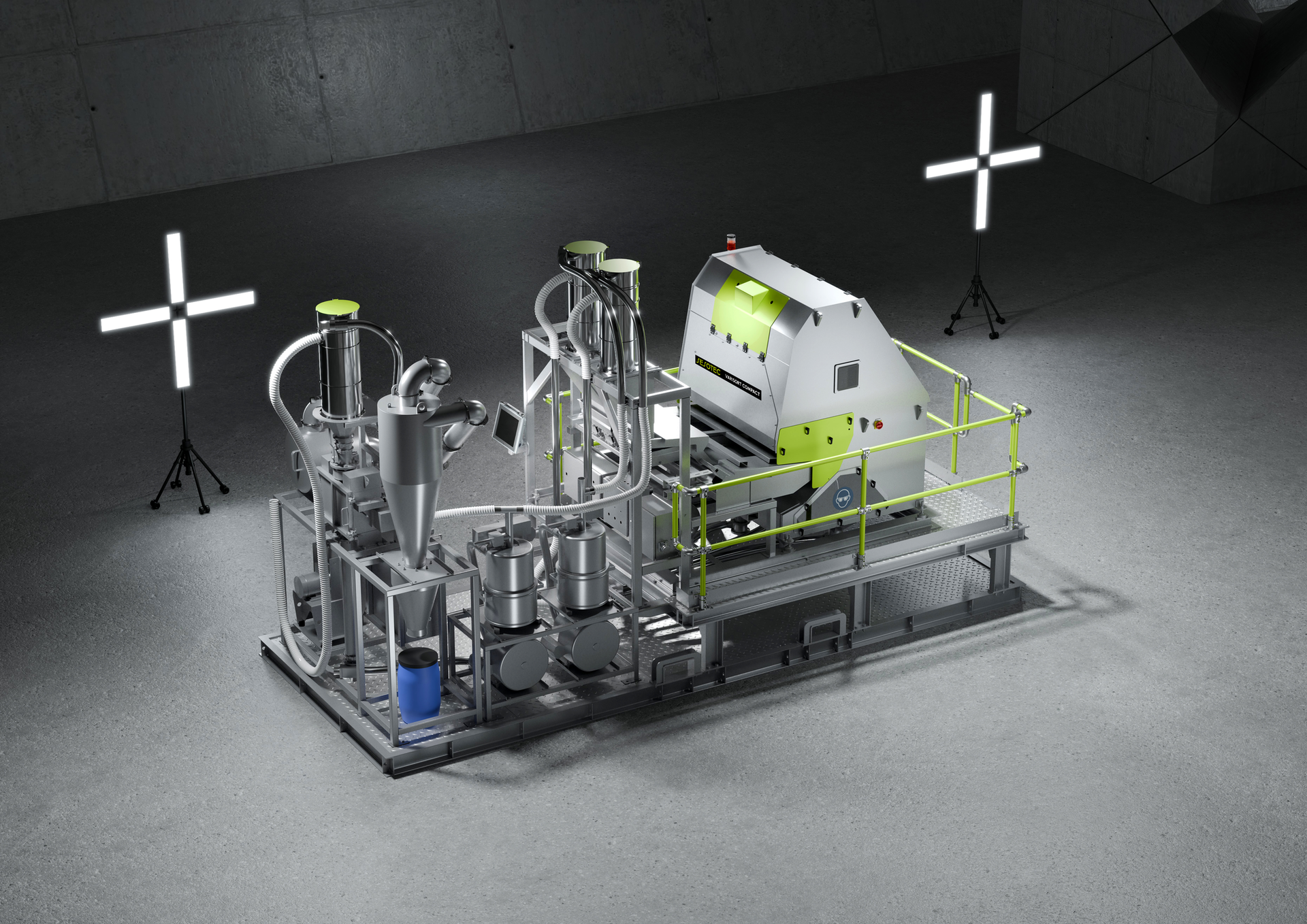

At the FAKUMA trade fair, Sesotec presents innovative solutions for an efficient and profitable circular economy. The centerpiece of the exhibition is, as in 2023, the PRE-SORT sorting platform. This combines the VARISORT COMPACT sorting system, dust extraction units, material conveying, and a central control into one complete solution. The system components have been further optimized to achieve even more precise sorting results. With a modular design of sorter, dust extraction, and conveying, the PRE-SORT platform offers easy access to the respective device components. Additionally, a maintenance area has been implemented that provides direct access to the control of each individual component.

Besides the PRE-SORT platform, Sesotec also presents other proven systems, including the metal detector GF, the metal separator unit RE-SORT, the metal separator RAPID VARIO with rotating separator unit, and the metal separator PROTECTOR for extruders, injection molding, and blow molding machines, as well as the material analysis system FLAKE SCAN.

New Features for Established Metal Separators

Another highlight at the fair is the new "Monitoring Package" for PROTECTOR metal separators, which addresses challenges such as fluctuating product quality, heterogeneous input material, and confusing process parameters.

The Monitoring Package is an optional sensor unit that directly captures parameters such as moisture, temperature, and color fluctuations of the material being processed on injection molding machines and extruders. This allows deviations to be reported to higher-level systems, enabling processes to be adjusted and ensuring the highest product quality. The Monitoring Package enables quick integration into the processing line, reduces plastic waste, and ensures a constant melting point for the conveyed material. In addition, the energy required for the melting process is reduced, which is environmentally friendly and increases profitability.

FLAKE SCAN Analysis System with New Features

The FLAKE SCAN analysis system from Sesotec has been enhanced with three new functions that significantly increase efficiency and user-friendliness.

1. Label Printer for Identifying Sample Bags: To facilitate direct assignment of analysis results to the respective samples, a label printer can now be connected. This feature allows labels to be printed that can be applied directly to BigBags or sample containers. This option is retrofittable, so existing FLAKE SCAN systems can also benefit from this new function.

2. Barcode Scanner for Simplified Batch Number Entry: For quicker and error-free entry of batch numbers, FLAKE SCAN now offers the possibility to connect a barcode scanner via the system's USB ports. This reduces the effort required for manual entry and minimizes the risk of input errors.

3. Particle Size Distribution: The enhanced FLAKE SCAN software now enables precise analysis of flake size. This function assists users in accurately determining the material's size distribution, which is crucial for optimizing the recycling process.

With these new features, the FLAKE SCAN analysis system offers even more precise and efficient analysis capabilities and makes a significant contribution to optimized plastic sorting.

Dietmar Dieing, Vice President Sales Plast at Sesotec, emphasizes the importance of the FAKUMA fair: "FAKUMA not only provides us with an ideal platform to present our innovative technologies, but also to intensify the dialogue with customers and partners. The fair underscores the importance of progress and sustainability in the plastics industry. For us, FAKUMA is more than just a fair - it is a showcase for the future of the entire plastics industry." Michael Perl, Group Director Sales Division Sorting Recycling, adds: “The plastics loop has evolved from a concept to an essential component of the modern plastics industry. The right sorting technologies, best combined with the use of AI, are the key to unlocking the true value of plastic waste and transforming it into high-quality, reusable materials.”

For more information about Sesotec's highlights at FAKUMA 2024, please visit the website www.sesotec.com/emea/de/lp/fakuma-2024.