The Reiling Group of Companies, with more than 100 years of experience, is constantly striving to create new opportunities for the optimal recovery and use of valuable materials. Reiling contributes to resource conservation as well as environmental and climate protection through efficient recycling processes.

In addition to recycling glass, photovoltaic panels, and wood, Reiling operates PET recycling plants at locations in Hamm, Marienfeld, and since 2020 also in Burgbernheim. Especially in the PET recycling cycle, the purity of the recycled end product is the prerequisite for rPET to be used in a variety of ways. The production of new PET bottles or the manufacture of polyester fibers are just two individual examples of the use of rPET. When the highest quality recyclate is used, the recycling cycle is closed. The need for the production of new goods moves into the background.

The problem: Extensive and at the same time complex quality controls in the multi-stage PET recycling process.

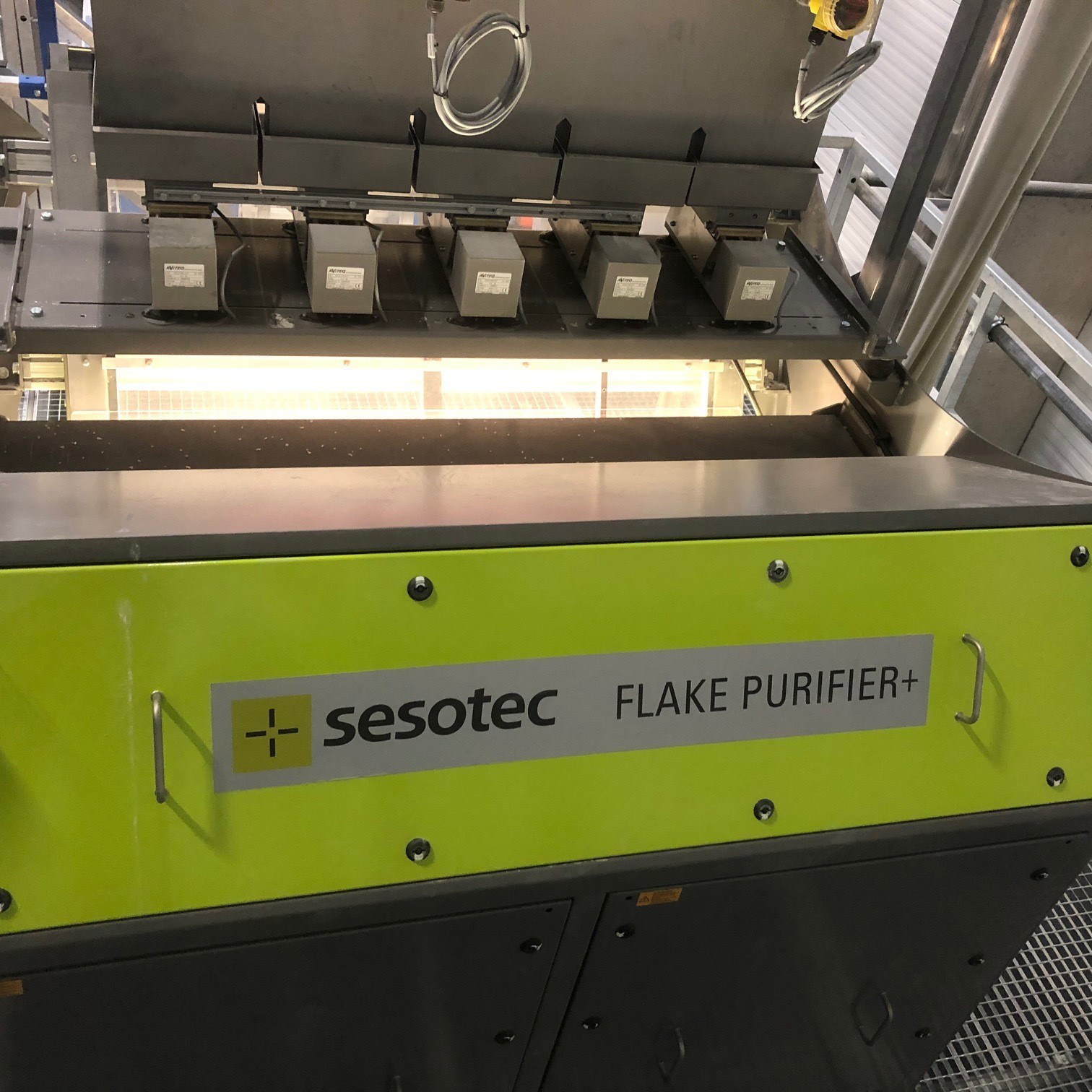

To produce recyclate of the highest quality and grade, Reiling Kunststoffrecycling relies on a multi-stage recycling process with state-of-the-art facilities. Only pure-grade recyclate can be reused for a wide range of new products. The PET bottles are delivered in the form of briquettes or bales. First, they are separated, then contaminants are removed, and the bottles are sorted by color. After crushing and washing processes, the PET flakes pass through the FLAKE PURIFIER+ sorting systems from Sesotec, which perform separation of colors and metals as well as sorting by types of plastic in a single pass.

In addition to state-of-the-art facilities, Reiling ensures through an internal quality management system throughout the entire processing process that only PET flakes of the highest purity leave the plant. To evaluate the recyclate in the recycling process, elaborate manual, thermal, and visual spot checks are necessary.

The solution: Reliable and precise laboratory analysis system ensures the highest quality in the end product.

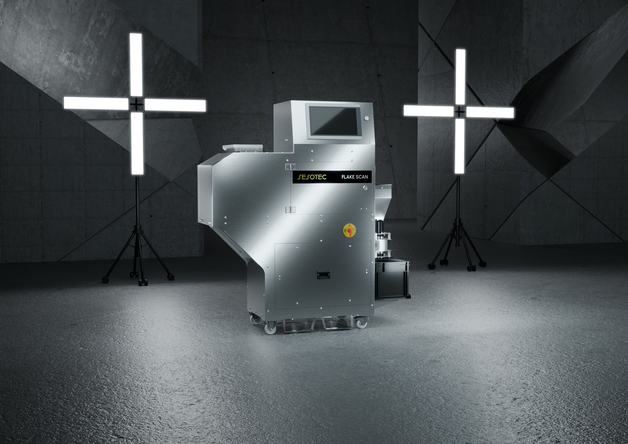

With the new laboratory analysis system FLAKE SCAN from Sesotec, Reiling is able to evaluate the quality of plastic flakes within a few minutes. This allows for quick and reliable decisions regarding the usability of the material. Every single BigBag and every silo delivery undergoes precise quality control. The Sesotec FLAKE SCAN material analysis system is installed directly in the facility. This allows material samples from each BigBag to be precisely and quickly examined and analyzed for foreign plastics, incorrect colors, and metals.

The customer benefit: Highest quality recyclate for a wide range of applications.

Dr. Hanns-Jörg Bentele, Managing Director of Reiling Kunststoffrecycling GmbH: "We had the opportunity to test the FLAKE SCAN shortly after its market launch and were convinced of its benefits after extensive trials. The FLAKE SCAN analysis system from Sesotec provides us with precise, automatic, and above all reproducible results in a significantly shorter time when analyzing material samples. The analysis system relieves the laboratory. This saves time and, of course, additional costs in this area."

The FLAKE PURIFIER+ sorting system and the FLAKE SCAN material analysis system from Sesotec make precision in material separation and quality monitoring possible. Sorting and analysis form a unit that helps achieve extremely high-quality secondary raw materials. Material cycles are closed. Sustainability, environmental protection, and profitability go hand in hand.

Download this case study as a document.