In the plastics processing industry, there are many reasons to use recyclate and thus close the plastic loop. Like all used plastics, regrind must be as pure as possible so that the material can be used as a secondary raw material. Technologies for material sorting and foreign body detection play a crucial role in eliminating impurities: Foreign bodies such as metals, different colors, and types of plastics must be efficiently and reliably detected and automatically separated or sorted in regrind to ensure the use as recyclate works. Pre-sorting is not only a tool for quality assurance but also an interesting approach to increasing profitability.

Challenges in Purchasing Ground Goods

The plastics processing industry is faced with constantly increasing demands: Two very important points regarding the material are the inconsistent material quality and the lack of material availability. There are not enough post-consumer recyclates (PCR) of consistently high quality, i.e., without foreign bodies, foreign colors, and foreign plastics in the material, to meet market demand. Furthermore, there are no specifications that clearly regulate the quality of a recyclate.

Other challenges in the procurement of regrind are fluctuating raw material prices, complex supply chains, and long delivery times.

Requirements of the Plastics Processors

- Material efficiency: First-class quality of the material to be processed is the prerequisite for risk-free further processing in the drying, mixing, or production process. If the quality is right, production can run smoothly and at maximum performance.

- Process safety: The removal of dust particles and foreign bodies from the input material prevents machine damage and ensures a safe process flow. A defective system costs time and money - on the one hand due to production downtime and on the other hand due to repair work.

- Quality assurance: The early detection of contaminants contributes to ensuring the highest quality of end products and prevents potential image damage and costly recalls.

- Cost-effectiveness: The use of regrind must be economically viable. Through pre-sorting, plastic processors are able to purchase input material with lower purity levels and therefore lower prices, while still producing in high quality.

Complete solution for the use of grinding materials

Plastics processors should be able to take the quality of their input material into their own hands so that they can produce sustainably and with process reliability using foreign material.

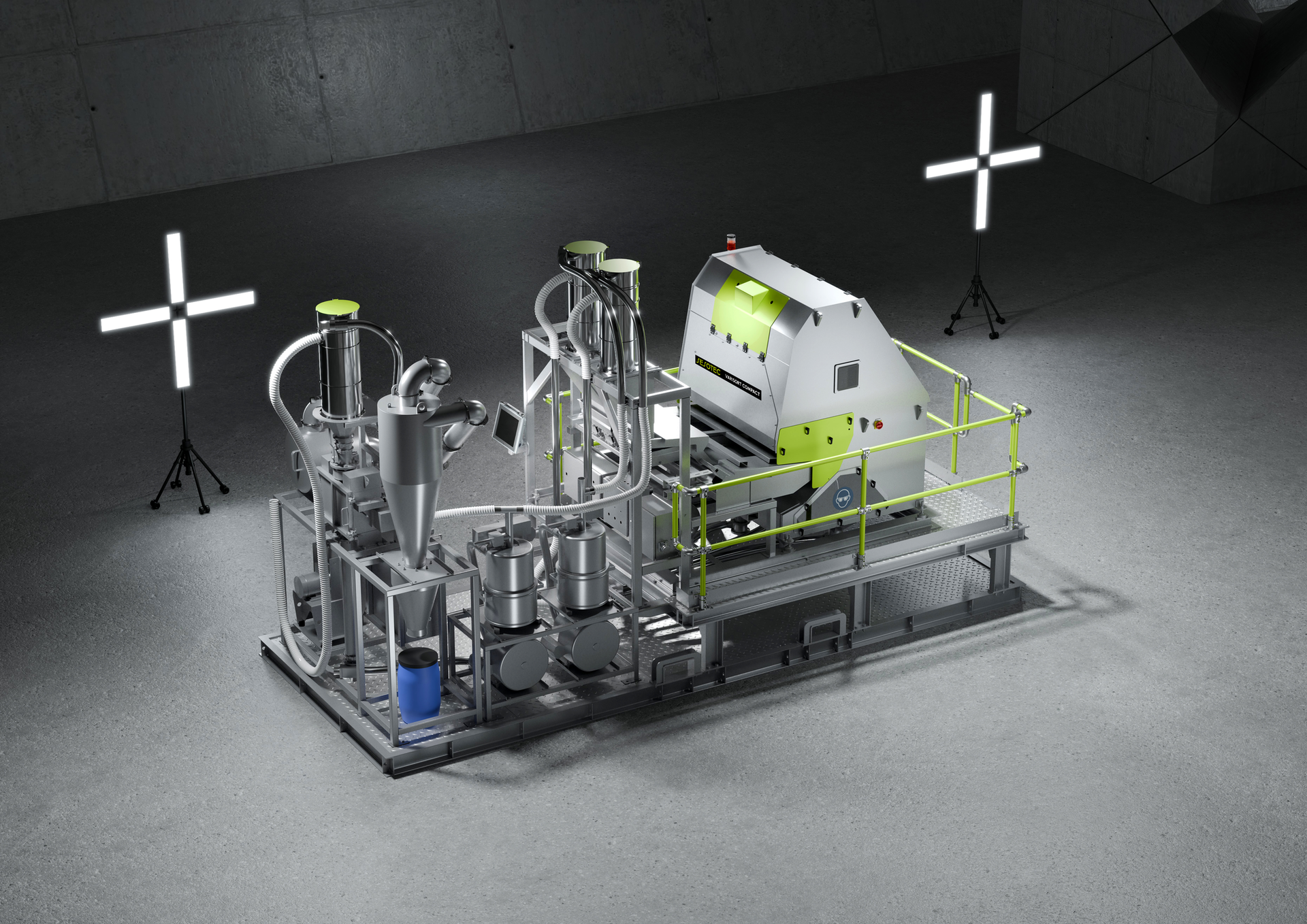

But how can this be achieved when quality, material availability, and prices are constantly fluctuating?The solution is pre- and post-sorting, which fully automated, efficient, and reliable, recognizes and separates types of plastics, colors, and metals from materials of various qualities according to the requirements of the production line. This pre-sorting can take place completely independently of the further processing process by, for example, combining all relevant process steps on a compact platform.

Important process steps in the presorting of plastics

- Dust removal: Dust and fine particles are reliably separated from the ground material by a counterflow sight system.

- Material transport: Standard suction conveying devices with a central vacuum station ensure smooth material transport over the dust removal to the sorter. The extraction can be done from containers, silos, big bags, or octabins.

- Sorting: A compact multi-sensor sorting system with high-resolution sensors that can be combined as desired. State-of-the-art signal evaluation technologies guarantee high detection accuracy and an evaluation of up to 500,000 parts per second. Possible sensors: color and shape sensor, metal sensor, and near-infrared sensor.

- Central control: The conveying technology and sorting are centrally connected via a control unit. An integrated automatic start and stop function ensures the highest possible operating comfort.

- Platform: A location-independent structural platform is designed for the rapid commissioning of the system. All necessary parts such as material transport, dust removal, and sorting are factory-installed and thus ready for use in the shortest possible time.

For every sorting requirement the right application

Plastics processors must flexibly handle input materials of varying qualities and different compositions.

Here are three examples of presorting:

Conclusion: Advantages of Pre-Sorting for Plastic Processors

Contaminations, color deviations, and visual defects impair the quality of plastics. The goal is to increase the purity of the regrind before processing, which automatically means more safety and higher quality of the end products.

The advantages of pre-sorting for plastic processors lie in producing more independently, profitably, and highly efficiently. A supply of high-quality and pure-grade material is ensured, enabling economical and efficient production – an investment that quickly pays off.

PRE-SORT by Sesotec.

Complex technology made simple, done efficiently.

The multi-sensor sorting on one platform offers:

- Mobility: Due to its design as a self-contained sorting platform, the PRE-SORT can be transported from one location to another, making it flexible and usable at different sites.

- Process Variability: By freely combining the sensors and selecting various sorting processes, the PRE-SORT offers maximum process flexibility. Thanks to two lanes for automated double sorting, the sorting platform also ensures top-notch material quality.

- Sensor Flexibility: Intelligent sensors for color, polymer, and metal sorting are combined in this device. Depending on the selected sensor combination, sorting can be done by colors, types of plastics, and metals, or only by individual factors.

Have we piqued your interest?

Speak with our experts