Nowadays, companies pursue both economic and ecological objectives. Profitability and sustainability are not in conflict but are of equal importance. In the food industry, quality is also of central importance. Food production and processing face numerous influencing factors, including fluctuating raw material prices, climate change, global population growth, and rising quality standards. To meet these challenges, companies must anchor food safety as a core point of their strategy in the global food industry.

Food safety should be consistently implemented and practiced throughout the organization. This can only be achieved through efficient process technology along the production chain. A consistent foreign body management, supported by advanced product inspection technologies and services, ensures profitability, conservation of resources, and compliance with regulations.

In particular, food safety plays a central role in the areas of management, production, and quality assurance; the diverse challenges must be mastered.

Would you like to be advised by our experts?

Contact us!

FAQs

Find out here, with the help of the following frequently asked questions, how targeted product inspection prepares you for the future and how you can find solutions for your priorities.

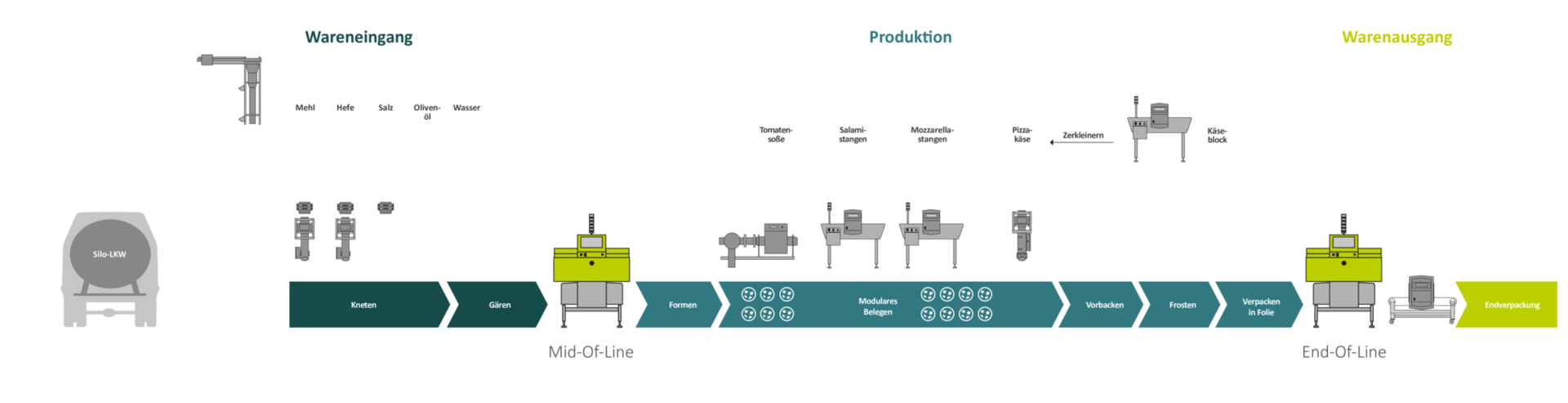

- How can product and process quality be maximized?With the best hardware and software solutions along your production line from goods receipt through production to goods dispatch

- How can you automatically adjust sensitivity settings to internal standards?With innovative software, sensitivity can be set to factory or audit standards at the push of a button. This reduces rejects and minimizes the loss of good material.

- How can you automate your compliance process?Continuous monitoring or an automatic function test module leads to immediate detection of deviations and increases the stability of the production process.

- How can you prove and document compliance with regulations?With a documentation tool that provides proof that the desired quality goals for the respective product are achieved.

- How do you compensate for strong product effects in your products?With artificial intelligence in its best form. This can achieve near-complete compensation of the product effect, metal detection in metallic packaging, and RFID tags.

- How do you have all relevant checkpoint information at a glance?With browser-based, intelligent data management. Software as a service that enables transparency, production optimization, customization, and documentation.

- How can Industry 4.0 become a reality?With the right software and hardware for digital networking, including a wide range of interface modules and secure compliance.

- How can the highest product quality be combined with the highest throughput?With innovative high-tech X-ray inspection, which works very quickly and reliably at up to 1000 pieces/min.

- How can the lifespan of machines be extended and the highest food safety ensured?With annual maintenance and warranty packages. The life of your equipment is extended with maintenance, repair, and retrofitting.

- How can you become more successful with not highly qualified operating personnel?With simple operating concepts in hardware and software design, e.g., auto-learn function.- Auto-learn function automates product-specific device settings- Audit check guides through the test routine and logs all steps- Continuous help menu supports the operator

- How can you automatically guide your operator through compliance processes?With an integrated process assistant tool that performs regular audit checks.

- How can you protect yourself from incorrect machine settings?With the checkpoint function of the detection devices. Checkpoints are used to restore product parameters, reconstruct individual products, and track changes.

- How can maximum security be achieved?With a higher-level security package that offers checkpoint functions. This exceeds international standards, SQF, IFS, FSSC 22000, BRC, etc.

- How can internal data protection and operational safety regulations be complied with?With the definition of different user groups, individual access rights, and a "Login2Go" function that stores the data on a USB stick - optionally RFID login.

- How can the highest hygiene standards be maintained?Simplified cleaning of X-ray devices through open, modular design, access and disassembly of the belt without tools, and suspension system for radiation protection curtains.

- How can you qualify your staff for X-ray devices?With an auto-learn function of the X-ray devices. The auto-learn function offers easy and intuitive operation. The configuration of the various filters is carried out by the device itself, and the detection sensitivity is automatically adjusted.

- How can you quickly get advice and help in machine emergencies?With remote maintenance via augmented reality. The augmented reality technology, which accesses your machine directly via an Ethernet connection, allows technicians and engineers to react very quickly.

Conclusion

Food safety, or in German Lebensmittelsicherheit, is not just a trendy buzzword, but a central element for companies in the food industry. This article makes it clear that high quality is not only ethically desirable but also economically sensible. In fact, profitability can only be achieved in the long term through consistent quality assurance. Companies committed to responsible food production recognize that food safety is paramount. It is not enough to conduct checks only at the end of the production chain. Effective assurance of food safety requires monitoring at every single control point of production.